Preparation method of a highly dispersed ruthenium-based catalyst and its application in the purification of chlorine-containing volatile organic pollutants

A ruthenium-based catalyst, highly dispersed technology, applied in the field of air pollution control, can solve environmental and human health hazards and other problems, achieve low-temperature catalysis, excellent low-temperature reducible performance, and avoid the effects of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

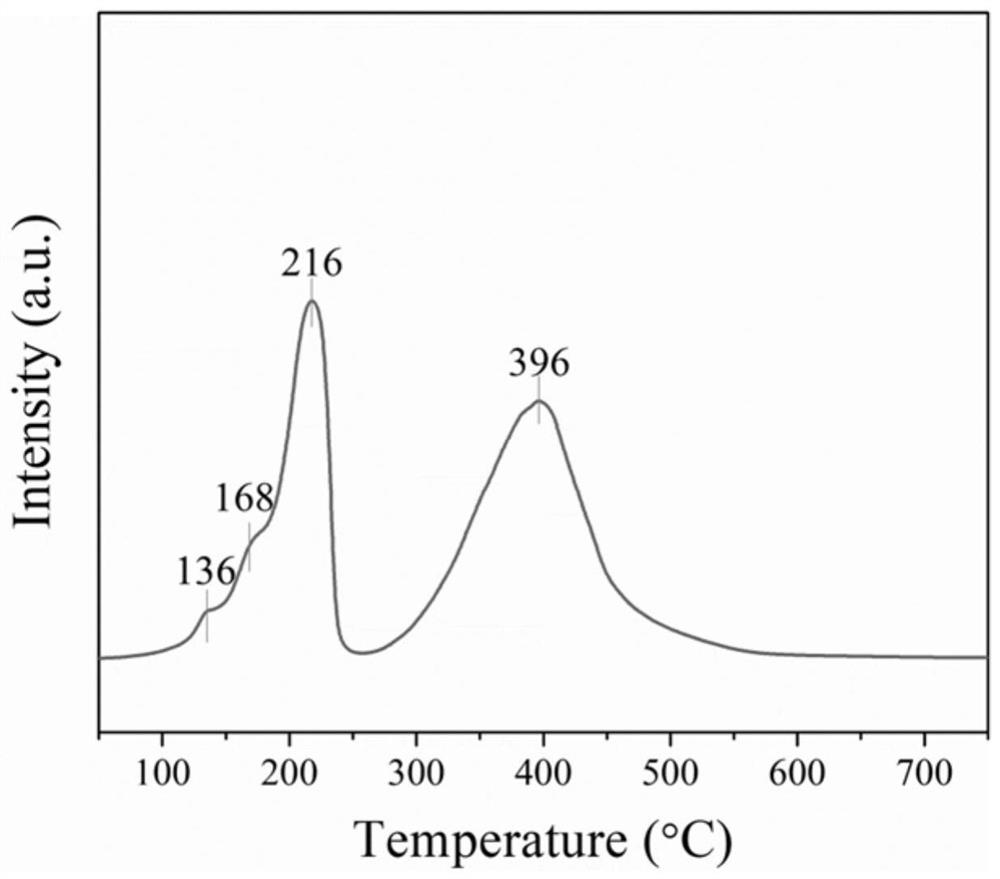

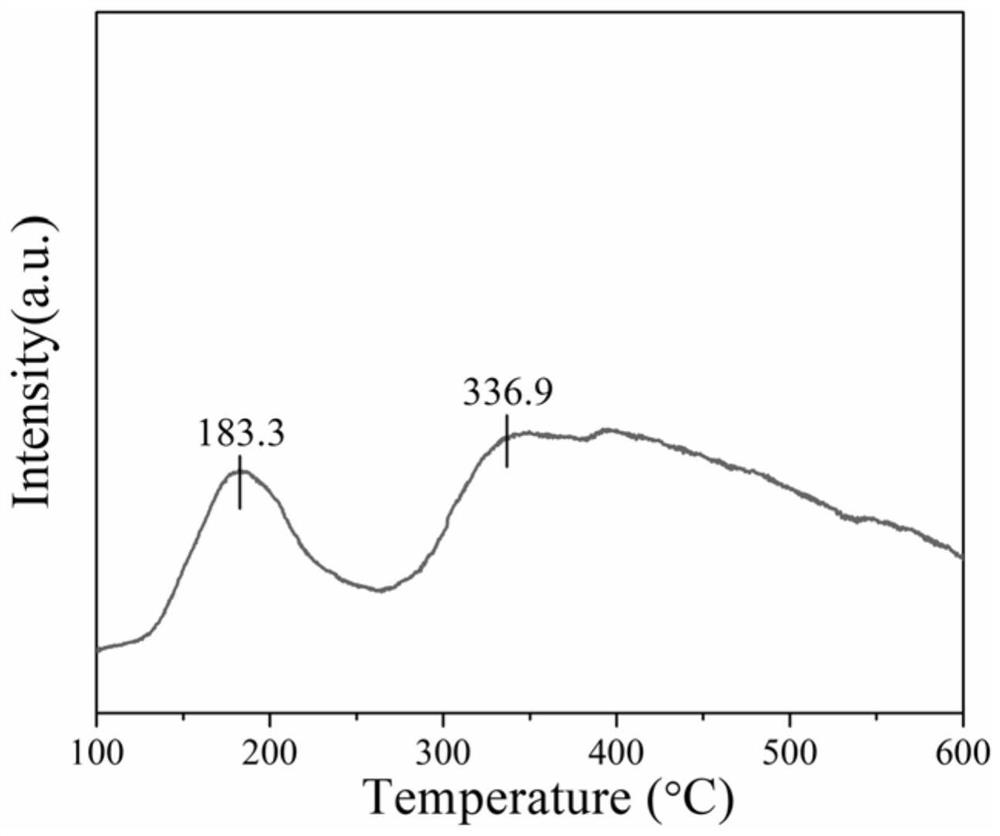

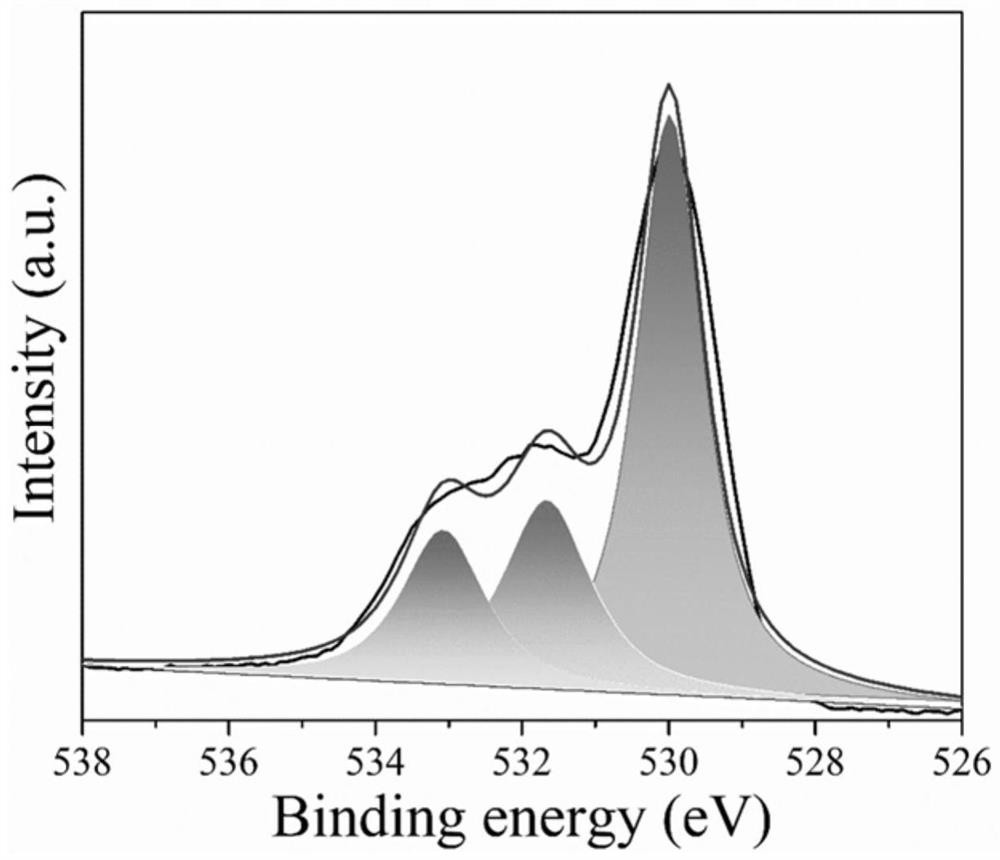

[0039] Example 1 Preparation of highly dispersed ruthenium-based catalytic materials by multi-phase co-precipitation method, thermal oxidation method, in-situ photochemical reduction deposition method combined with thermal reduction

[0040] Dissolve 0.4g of potassium permanganate in 500mL of deionized water, stir at 600r / min for 20min at room temperature until completely dissolved and form a clear and transparent solution, and first heat the solution to 60 degrees; then add dropwise Completely dissolved 30mL containing 2.0g of cobalt sulfate solution, after the dropwise addition is completed, stir for 2 hours to promote the solution to fully react, then raise the mixed solution system to 80 degrees and continue to stir for 2 hours, then let the mixed solution naturally cool and stand 6h, then the solution was filtered to obtain a black solid powder.

[0041] The prepared black powder was redispersed in deionized aqueous solution, and a certain amount of precious metal source ...

Embodiment 2

[0042] Example 2 Activity Test and Evaluation of Catalytic Degradation of 1,2-Dichloroethane by Highly Dispersed Ruthenium-Based Catalytic Material

[0043] Get the solid powder tableting obtained in Example 1, sieve (40-60 mesh), and accurately take by weighing 0.5g catalyzed material after sieving with 1,2-dichloroethane as probe gas, the reactant The concentration was controlled at 1000ppm, the reaction space velocity was 42000mL / g h and the oxygen concentration was 21%. °C, 330 °C and 340 °C) catalytic activity, and the reaction products were monitored and analyzed by gas chromatography.

Embodiment 3

[0044] Example 3 Stability Test of Catalytic Degradation of 1,2-Dichloroethane by Highly Dispersed Ruthenium-Based Catalytic Material

[0045] Get the solid powder obtained in Example 1 and press into tablets, sieve (40-60 mesh), accurately weigh 0.5g of the catalytic material after sieving and place it in the fixed bed of the evaluation device, and use 1,2-dichloroethane Alkanes are used as probe gas, the concentration of reactants is controlled at 1000ppm, and the reaction space velocity is 42000h -1 And the oxygen concentration is 21%, the catalytic reaction activity of the catalyst at 300° C. is continuously tested, and the reaction product is monitored and analyzed by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com