Composite adsorbing material and preparation method and application thereof

An adsorption material and composite technology, applied in the field of material preparation and environmental science, can solve the problems of high technical requirements for synthesis process, high toxicity of synthetic raw materials, complex synthesis method, etc., and achieves strong operability, remarkable removal effect, and synthesis process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

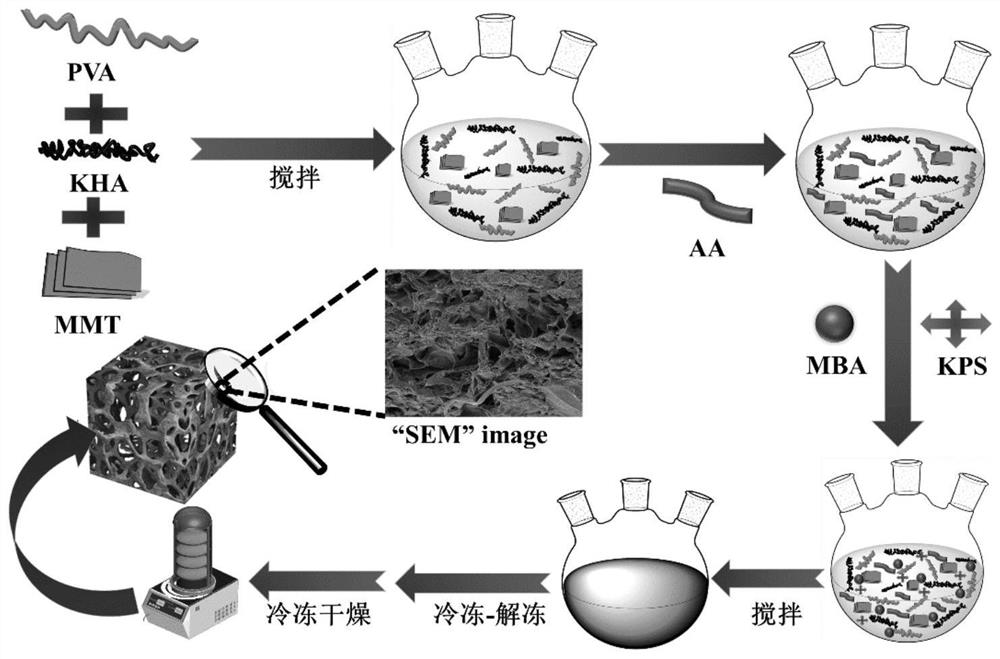

[0043]10 g 10% polyvinyl alcohol solution, 10 g of sodium hydrate solution and 6 g of 0.5% sodium monosil water dispersion solution were mixed at 55 ° C, and mixed with a rotational speed of 100 r / min, and mixed with mixed liquid A.

[0044]Then, 10 g of 0.2% N, N'-methylene double acrylamide solution was added to the acrylic solution of 20%, forming a mixed liquid B and dripped into mixed liquid A at a speed of 3 drops / S. At the same time, 10 g of 0.4% ammonium sulfate solution 2 drops / S was dripped into mixed liquid A. After the above solution is added, the mechanical stirring lasts for 20 min, warmed to 70 ° C, and stirring for 2 h, resulting in a viscous gel material. The gel material was placed in -4 ° C for 6 h, which was subjected to thawing 6 h under room temperature conditions, and the same condition and the freezing were frozen 3 times, and then placed in a cryogenic dryer to give a composite adsorbent material.

Embodiment 2

[0046]15 g 8% polyvinyl alcohol solution, 10 g of 0.8% hydrorate solution and 8 g 1.0% calcium-monovolid water dispersion solution were mixed with 60 ° C, and mixed with a rotational speed of 125 R / min.

[0047]A 10 g of 0.3% N, N'-methylene bis acrylamide solution was added to an acrylic solution of 40 g of an acrylic solution to form a mixed liquid B and dripped into mixed liquid A at a speed of 4 drops / S. At the same time, 10 g of 0.7% potassium sulfate solution was added dropwise to the mixture A. After the above solution is added, the mechanical stirring lasts for 30 min, warmed to 70 ° C, continued to stir for 3 h, resulting in a viscous gel material. The gel material was placed in -4 ° C for 9 h, and then thawed 9 h under room temperature conditions, the same conditions and the freeze were frozen 4 times, and then lyophilized in the cryogenic dryer to obtain a composite adsorbent material.

Embodiment 3

[0049]20 g 6% polyvinyl alcohol solution, 10 g of 1.5% hydrorate solution and 10 g of 1.5% sodium monosil dispersion solution were mixed with 65 ° C, and mixed with a rotational speed of 150 r / min, and mixed with mixed liquid A.

[0050]10 g of 0.5% N, N'-methylene double acrylamide solution was added to an acrylic solution of 60 g of an acrylic solution to form a mixture B and dripped into mixed liquid A at a speed of 5 drops / S. At the same time, 10 g 1.0% of ammonium sulfate solution was added dropwise to the mixture A. After the above-mentioned solution is added, the mechanical stirring lasts for 40 min, warmed to 70 ° C, and stirring for 4 h, resulting in a viscous gel material. The gel material was prepared in -4 ° C for 12 h, which was subjected to thawing 12h under room temperature conditions, and the same conditions and the freezing were frozen 5 times, and then placed in a cryogenic dryer to obtain a composite adsorbent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com