Processed cheese with long shelf life and preparation method thereof

A technology for remanufactured cheese and shelf life, applied in dairy products, cheese substitutes, applications, etc., to achieve the effects of easy operation, excellent texture and taste, and convenient consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

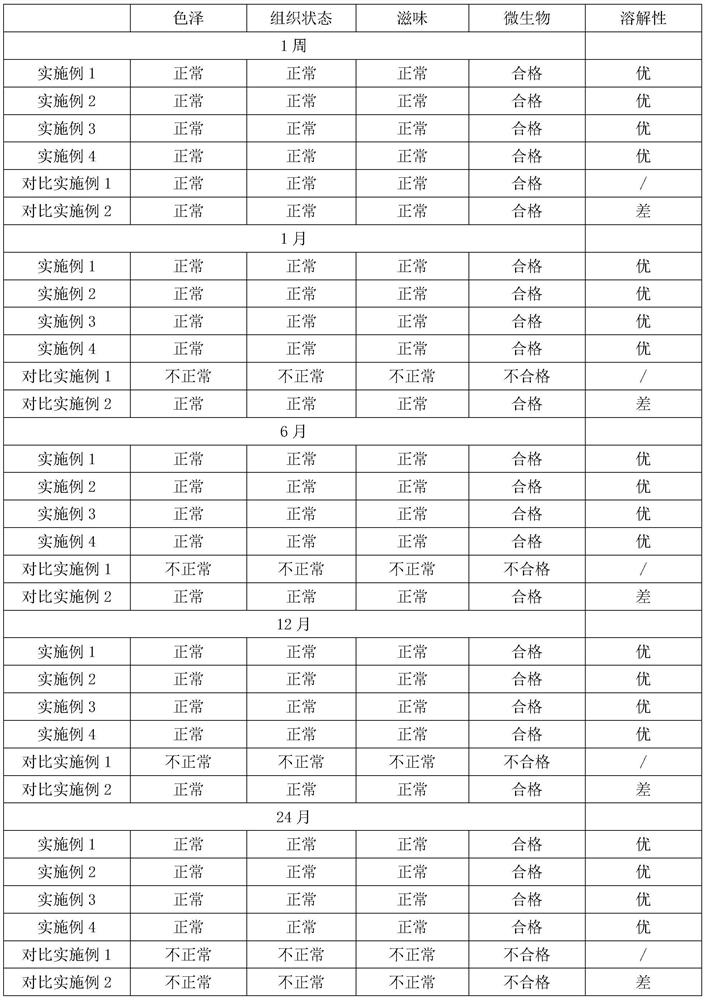

Examples

preparation example Construction

[0023] A method for preparing processed cheese with a long shelf life of the present invention, the raw materials include 3-7% casein, 50-65% natural cheese, 1-3% whole milk powder, 1.5-2.5% emulsifying salt, 8 -10% butter, the balance water;

[0024] The preparation method includes the following steps: (1) mixing casein, whole milk powder and emulsifying salt, and pre-mixing uniform auxiliary materials under the condition of 20-30°C; cutting natural cheese into pieces, and obtaining a size not exceeding 10*10* 20cm cheese block; mix the pre-mixed auxiliary materials, cheese block, butter and water, stir and heat to 85-95°C, keep warm and stir for 5-10min; (2) thick cheese sauce obtained in step (1) Carry out homogenization operation;

[0025] (3) the mixture of step (2) is instantaneously sterilized by ultra-high temperature;

[0026] (4) The base material obtained in step (3) is spray-dried through a spray tower to obtain raw material powder, which is cooled and packed. M...

Embodiment 1

[0042] Raw material formula: 3% rennet casein, 65% cheddar cheese, 1% whole milk powder, 8% butter, 1.5% emulsifying salt, and supplement the balance with water.

[0043] Preparation:

[0044] (1) Mix the raw materials of the powder, and mix evenly at 20°C; cut the cheese into pieces, the size of which should not exceed 10*10*20cm. Mix the pre-mixed auxiliary materials with the cheese, stir and heat to 85°C, keep stirring for 10 minutes;

[0045] (2) Homogenizing the thick cheese sauce obtained in step (1) under a pressure of 80 bar;

[0046] (3) The mixture is sterilized by ultra-high temperature instantaneously, and the sterilization condition is 135°C for 9s;

[0047] (4) The base material obtained in step (3) is spray-dried through a spray tower, the inlet temperature is 120-140° C., and the outlet temperature is 70-80° C. to obtain raw material powder to obtain raw material powder, which is cooled and canned;

[0048] (5) Mix the cheese powder obtained in step (4) with...

Embodiment 2

[0050]Raw material formula: 7% rennet casein, 50% cheddar cheese, 3% whole milk powder, 10% butter, 2.5% emulsifying salt, and supplement the balance with water.

[0051] Preparation:

[0052] (1) Mix the raw materials of the powder, and mix evenly under the condition of 30°C; cut the cheese into pieces, the size of which should not exceed 10*10*20cm. Mix the pre-mixed auxiliary materials with the cheese, stir and heat to 95°C, keep stirring, and keep warm for 5 minutes;

[0053] (2) Homogenizing the coarse cheese sauce obtained in step (1) under a pressure of 100 bar;

[0054] (3) The mixture is sterilized by ultra-high temperature instantaneously, and the sterilization condition is 140°C, 4s;

[0055] (4) The base material obtained in step (3) is spray-dried through a spray tower, the inlet temperature is 120-140°C, and the outlet temperature is 70-80°C to obtain raw material powder, which is cooled and canned;

[0056] (5) Mix the cheese powder obtained in step (4) with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com