Three-phase doubly salient motor with non-uniformly distributed stator pole widths

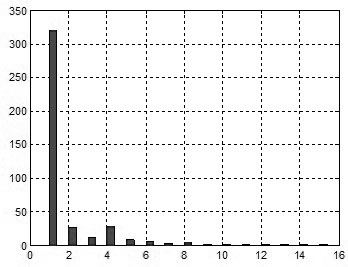

A double-saliency motor with uniform distribution technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of motor commutation torque ripple, increase of excitation loss, and longer current commutation time, etc., to achieve reduction Output torque ripple, improve running performance, and reduce the effect of harmonic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

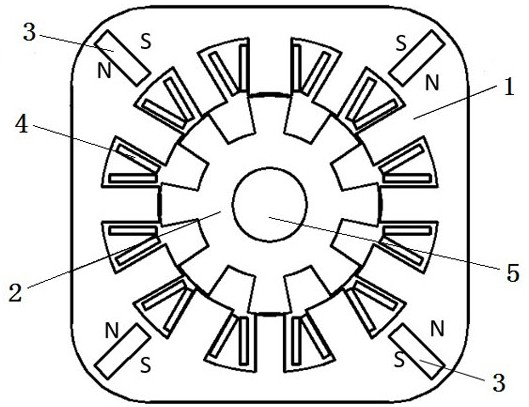

[0033] Embodiment one: if Figure 1-4 and Figure 7-8 , a three-phase double-salient pole motor with uneven distribution of stator pole width, including a stator core 1, a rotor core 2, an excitation element 3, an armature winding 4 and a rotating shaft 5, the rotor core 2 is arranged inside the stator core 1, and the rotor The core 2 can rotate relative to the stator core 1; the rotating shaft 5 is set inside the rotor core 2, and the rotating shaft 5 can rotate together with the rotor core 2; the excitation element 3 is set on the yoke of the stator core 1, which is the air gap magnetic field of the motor Provide excitation; the armature winding 4 is wound on the stator pole of the stator core 1, and the rotor core 2 is provided with the rotor pole. Rotation, the extreme width of the rotor poles is evenly distributed, and the extreme width of the stator poles is unevenly distributed.

[0034] The rotor core 2 has a salient pole structure, the number of rotor poles is 8, th...

Embodiment 2

[0043] Embodiment two: if Figure 5-8 As shown, a three-phase double-salient pole motor with unevenly distributed stator pole widths includes a stator core 1, a rotor core 2, an excitation element 3, an armature winding 4 and a rotating shaft 5, and the rotor core 2 is arranged inside the stator core 1. And the rotor core 2 can rotate relative to the stator core 1; the rotating shaft 5 is set inside the rotor core 2, and the rotating shaft 5 can rotate together with the rotor core 2; The gap magnetic field provides excitation; the armature winding 4 is wound on the stator pole of the stator core 1, and the rotor core 2 is provided with the rotor pole. The rotor rotates, the extreme width of the rotor poles is evenly distributed, and the extreme width of the stator poles is unevenly distributed.

[0044] The rotor core 2 has a salient pole structure, the number of rotor poles is 8, the rotor pole arc coefficient is 0.5, and the rotor poles adopt a fan-shaped tooth structure or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com