A built-in alternating pole permanent magnet motor based on rotor complementary structure

A technology of permanent magnet motor and alternating poles, which is applied in the shape/style/structure of the magnetic circuit, the shape/style/structure of the winding conductor, the magnetic circuit, etc., and can solve the asymmetry and torque ripple of the magnetic circuit with different polarity and alternating poles Excessive size, complex motor structure, etc., achieve the effect of saving permanent magnet materials, maintaining a balance between positive and negative amplitudes, and reducing the difficulty of manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically described below according to the accompanying drawings:

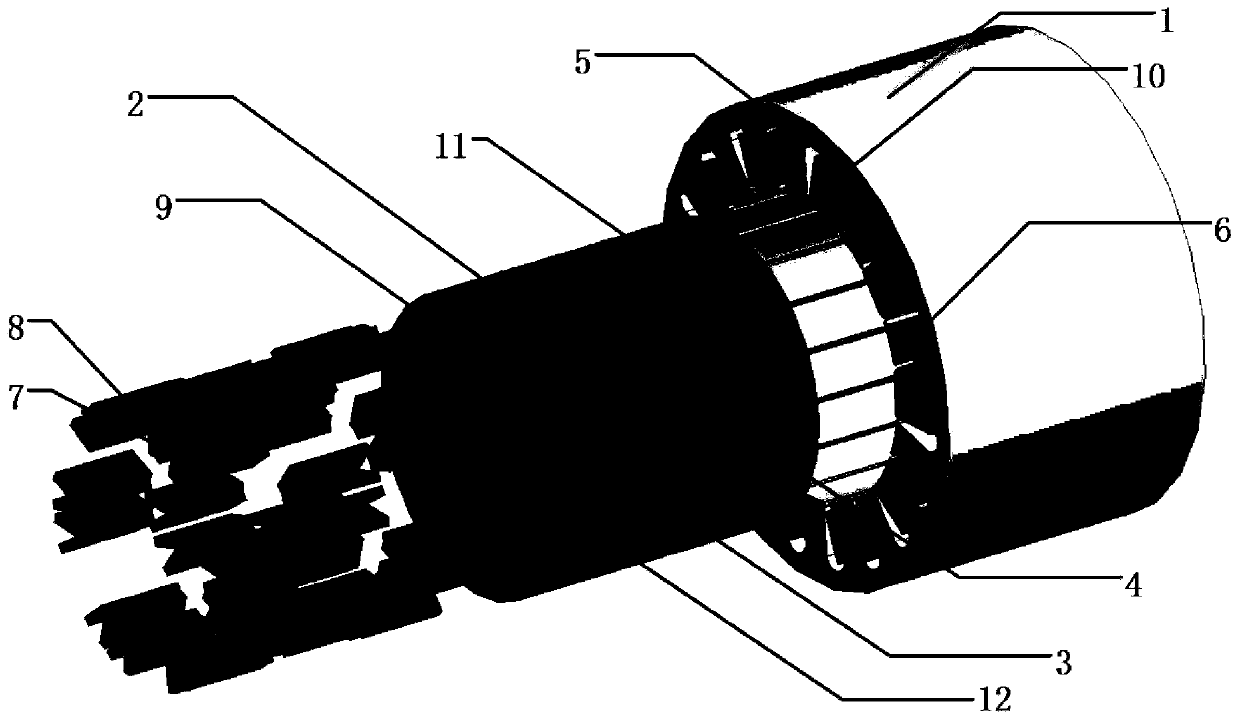

[0026] like figure 1 As shown, it is a built-in alternating pole permanent magnet motor based on the complementary rotor structure, including a stator 1, a first rotor 2, a second rotor 3, a third rotor 4, armature teeth 5, fault-tolerant teeth 6, S permanent Magnetic pole 7 , N permanent magnet pole 8 , iron core pole 9 , armature winding 10 , first magnetic isolation sheet 11 and second magnetic isolation sheet 12 .

[0027] by the following formula

[0028]

[0029] Set the number of pole pairs P of the first rotor 2, the second rotor 3, and the third rotor 4 r If both are 9, it can be deduced that the number of stator slots S is 20. Among them, a is a constant (usually the value is 1), and b is the number of motor phases 5. The armature teeth 5 and the fault-tolerant teeth 6 are arranged alternately in turn to improve the self-inductance of the motor and reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com