Pure oxygen smelting device of flash furnace and using method of pure oxygen smelting device

A smelting device and flash furnace technology, which is applied in the direction of furnace control device, furnace, furnace cooling, etc., can solve the problem that the temperature of the flue gas inlet of the electrostatic precipitator is too high, the blower load cannot be fully utilized, and the high-load production of the flash furnace is limited To achieve the effect of optimizing the heat distribution structure, reducing the total heat intensity, and reducing the number of times of coke cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

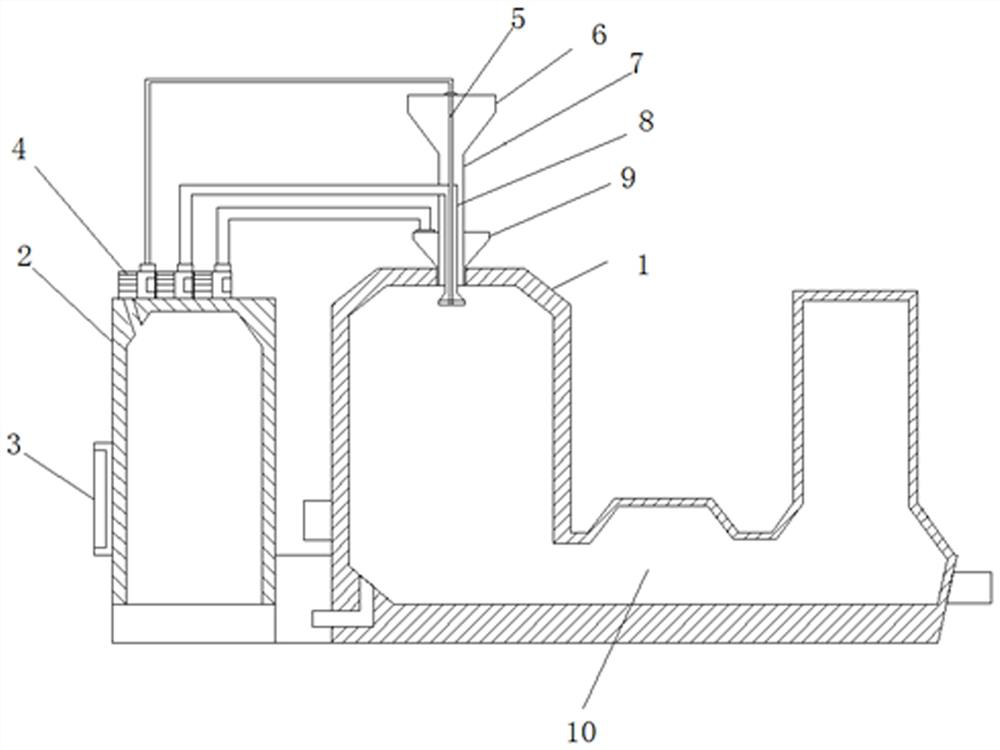

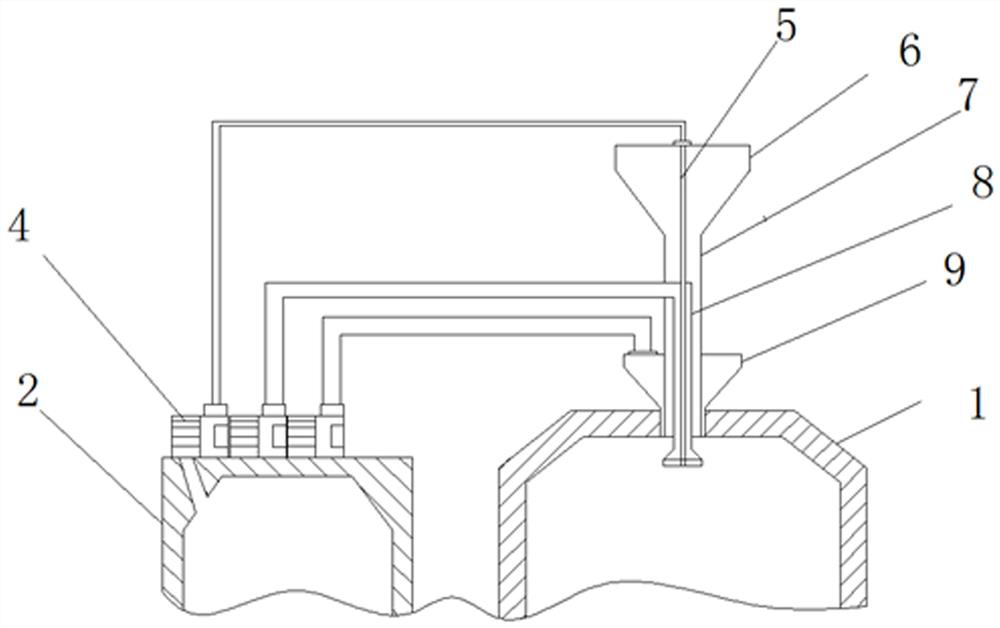

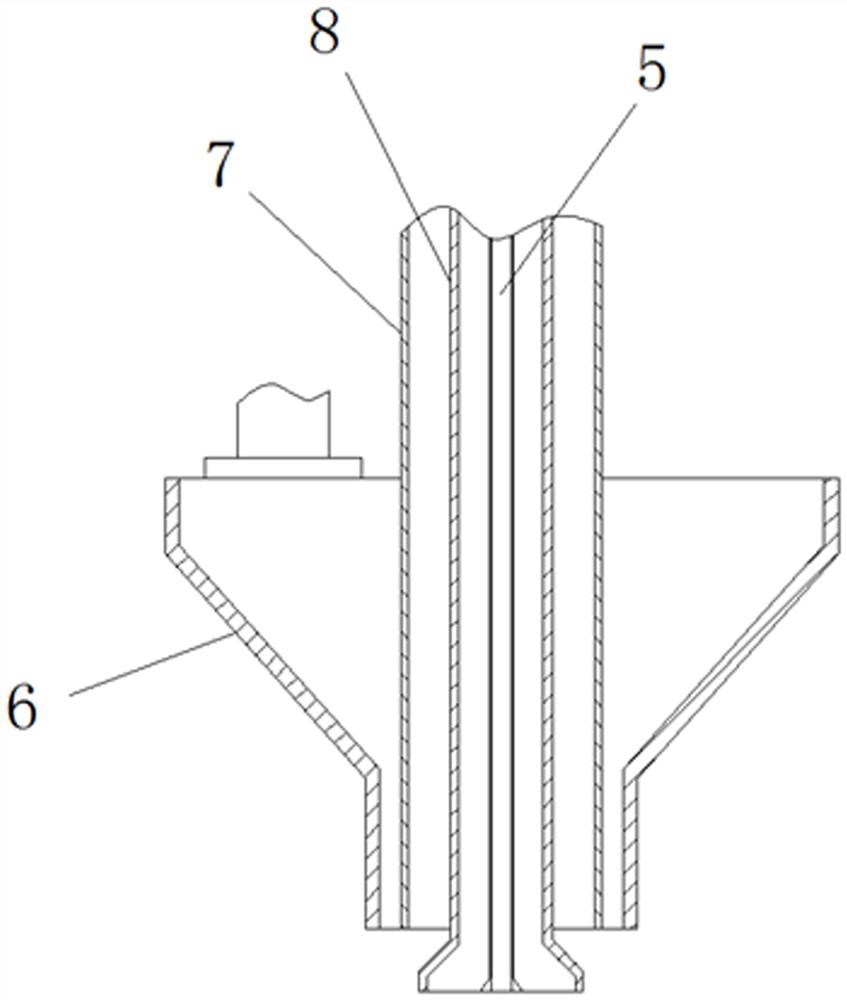

[0024] like Figure 1-4 As shown, a flash furnace pure oxygen smelting device of this embodiment includes a furnace body and a material supply device 6. The top of the reaction tower 1 of the furnace body is provided with a nozzle with an opening downward; the bottom of the nozzle is The opening extends into the reaction tower 1; the nozzle includes a central oxygen pipeline 5, a material pipeline 7, a dispersed oxygen pipeline 8 and a process oxygen pipeline 9, and a material pipeline 7 is installed in the process oxygen pipeline 9, and a dispersed oxygen pipeline is installed in the material pipeline 7. Pipeline 8, a central oxygen pipeline 5 is installed in the dispersed oxygen pipeline 8; the top opening of the material pipeline 7 is connected to the material supply device 6; it also includes an oxygen tank 2; the top of the oxygen tank 2 is provided with three oxygen pumps 4, each Two oxygen pumps 4 are respectively connected to the central oxygen pipeline 5, the disperse...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that: the bottom of the oxygen dispersing pipeline 8 is provided with a dispersing nozzle, the opening of the nozzle is inclined outward, and the central oxygen pipeline 5 passes through the dispersing nozzle. The dispersing nozzle makes most of the oxygen and materials discharged into the process oxygen pipeline divergent and sprays, further balances the oxygen supply ratio of the material reaction, and reduces flue gas emissions.

[0028] The working principle of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 2 lies in that divergent injection holes are evenly arranged on the outside of the dispersing nozzle. The divergent injection holes are evenly arranged on the outside of the dispersing nozzle, which provides a dispersing nozzle that injects oxygen laterally, and meets the requirements of high-load production, more material discharge and process oxygen pipeline discharge, and higher spray intensity.

[0031] The working principle of this embodiment is the same as that of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com