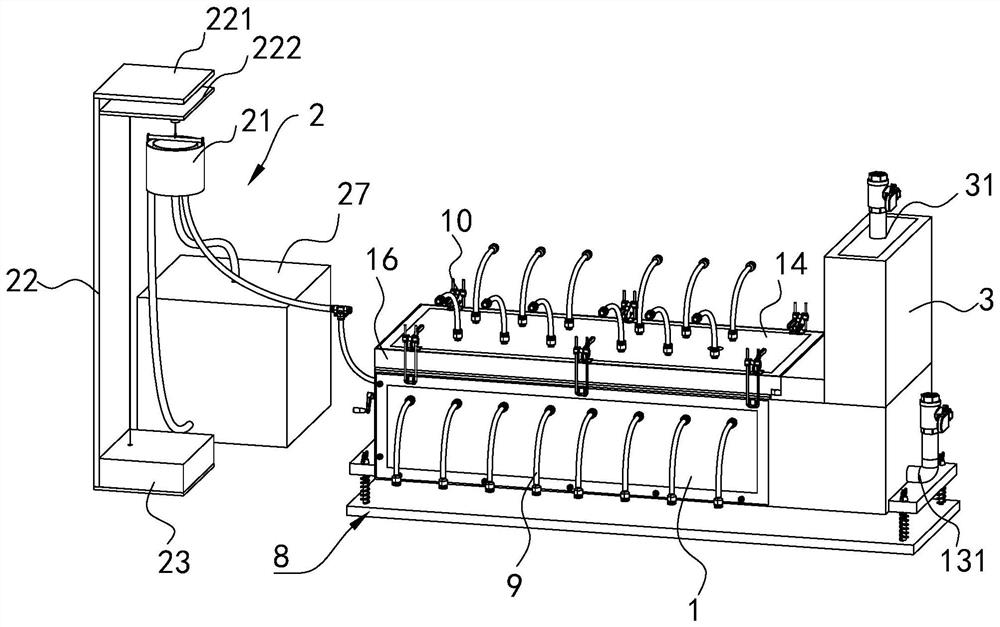

A simulation device and test method for short cut-off wall to control the development of embankment piping

A technology of simulation device and test method, which is applied in the direction of measurement device, hydraulic model, permeability/surface area analysis, etc., and can solve the problem of anti-seepage wall damage to control piping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

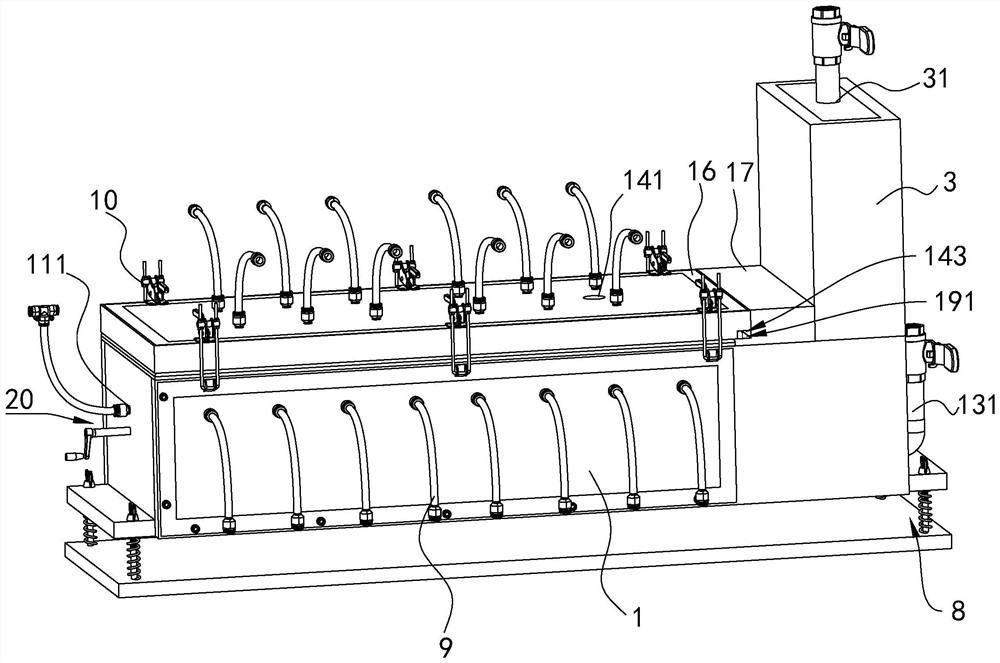

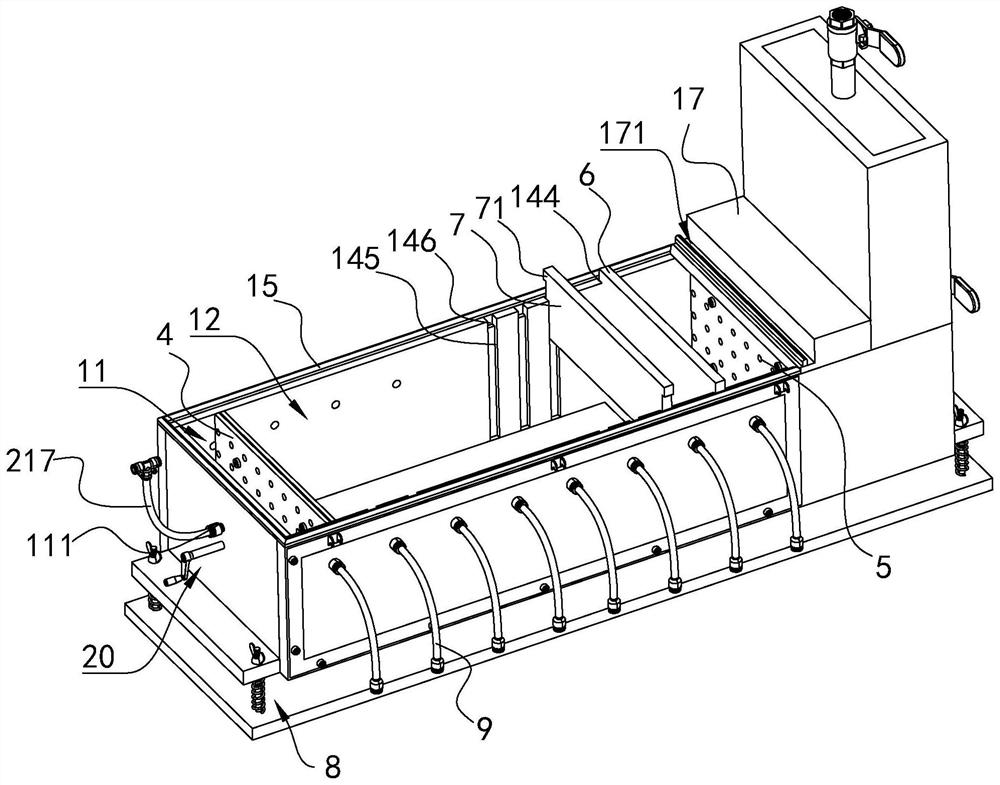

[0080] The test method for the short-wall simulator to control the development of embankment piping includes the following steps:

[0081] S1. According to the determined infiltration path length, the first infiltration assembly 4 is moved to the design position by the propulsion mechanism 20, and the anti-seepage short wall 7 is inserted into the second slot 145 according to the set penetration degree and position, and then to the second slot 145. The sand sample filling chamber 12 between the first diafiltration assembly 4 and the second diafiltration assembly 5 is filled with sand samples.

[0082] Sand samples can be filled with single-layer sand samples, double-layer sand samples or three-layer sand samples according to the test requirements to simulate single-layer embankment foundations, double-layer embankment foundations or three-layer embankment foundations.

[0083] The filling of the sand sample is carried out by layered underwater throwing, scraping and compacting...

Embodiment 2

[0094] The test method for the short-wall simulator to control the development of embankment piping includes the following steps:

[0095] S1. According to the determined infiltration path length, the first infiltration assembly 4 is moved to the design position by the propulsion mechanism 20, and the partition plate 6 is inserted into the first slot 144, and the anti-seepage short wall 7 is set according to the penetration degree and the position is inserted into the second slot 145, and then the sand sample is filled between the first infiltration assembly 4 and the partition 6.

[0096] Sand samples can be filled with single-layer sand samples, double-layer sand samples or three-layer sand samples according to the test requirements to simulate single-layer embankment foundations, double-layer embankment foundations or three-layer embankment foundations.

[0097] The filling of the sand sample is carried out by layered underwater throwing, scraping and compacting, each layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com