Spring contact finger service life testing method and tool

A spring contact finger and life testing technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of high cost, 3-5 months or even longer time from complete set to completion of the test, and long cycle, etc. problems, to achieve the effect of easy operation and simple and convenient test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

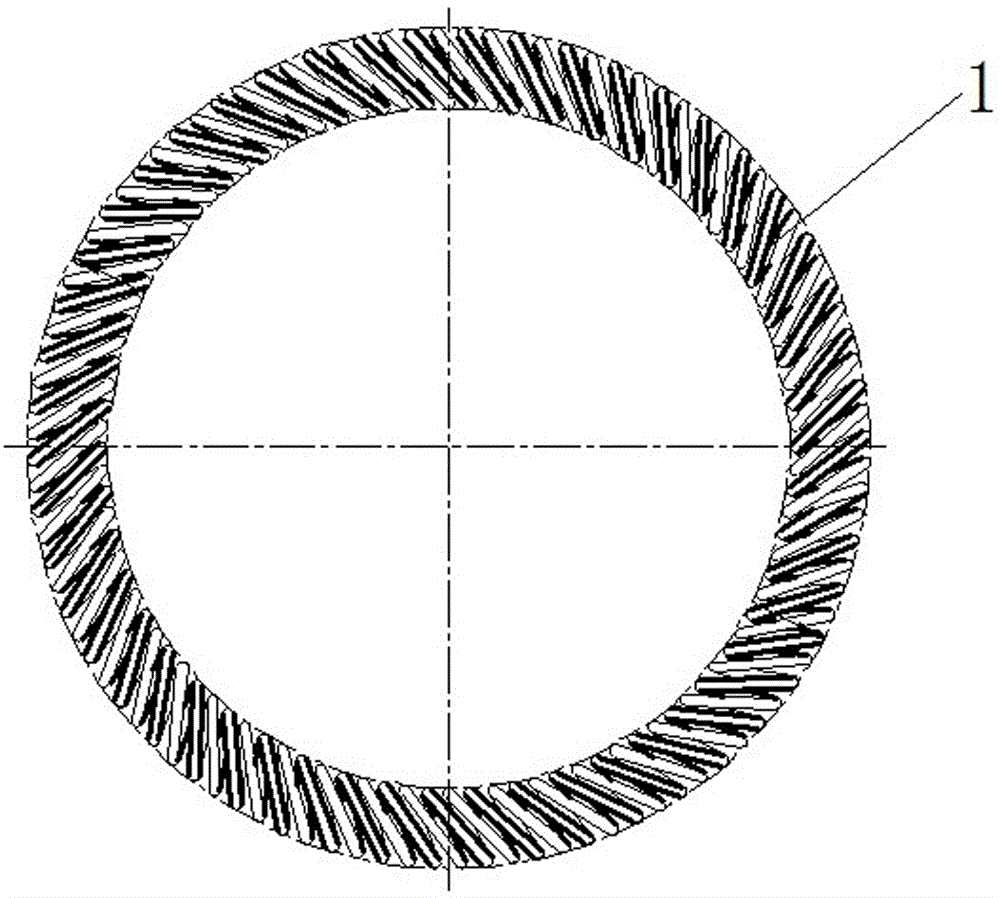

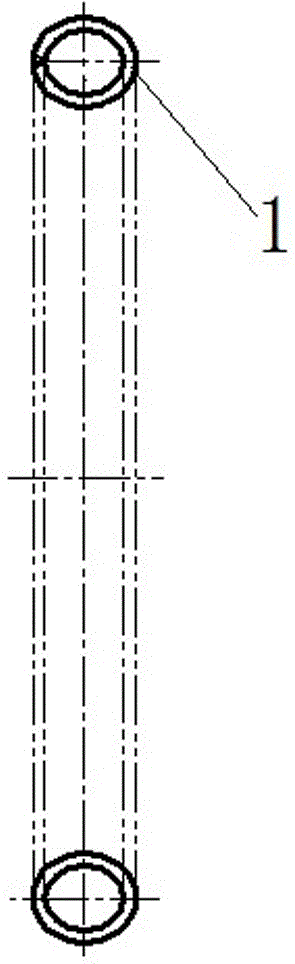

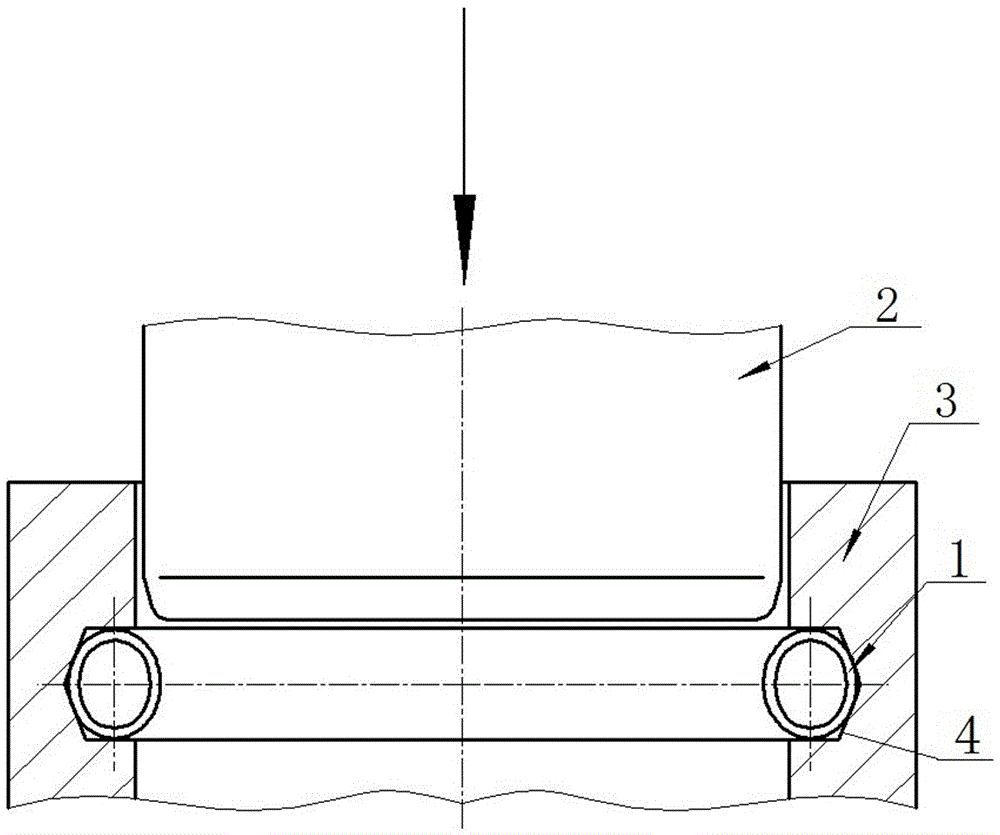

[0018] The specific embodiment of spring finger life test method of the present invention, as image 3 As shown in the figure, 1 is the spring contact finger, 2 is the contact head, 3 is the contact seat, and 4 is the positioning ring groove of the contact seat. Install the spring contact finger 1 in the positioning ring groove 4 of the contact seat 3, and ensure that the arc surface of the inner diameter of the spring contact finger 1 protrudes from the notch of the positioning ring groove 4 during installation. The contact 2 is arranged coaxially with the spring contact finger 1 and the contact 2 can move along the axial direction. When in use, insert the contact 2 into the spring contact finger 1 along the axial direction and squeeze the inner diameter of the spring contact finger. Repeat the above actions and use the counter to accumulate the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com