Oil removal method for metal part

A metal parts, alkaline degreasing technology, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of easily damaged metal parts, unsatisfactory electroplating effect, etc. The effect of reducing adhesion and promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

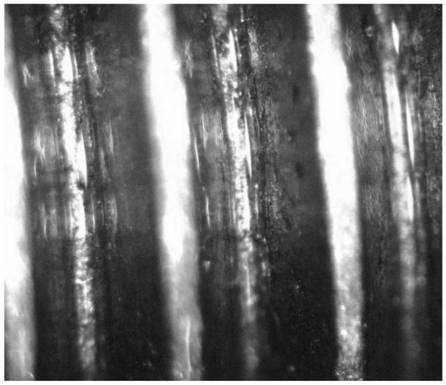

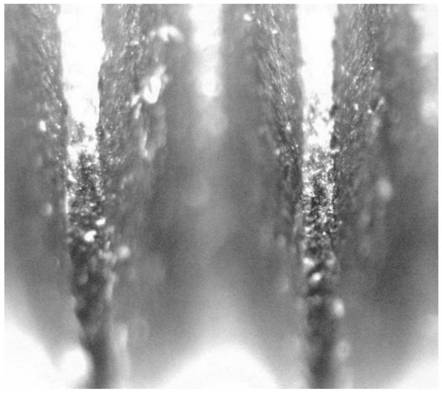

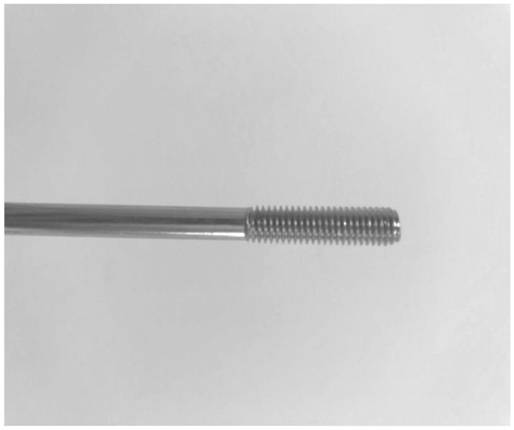

Image

Examples

Embodiment 1

[0043] The metal parts made of carbon steel provided by Xiongxin Electroplating Factory are degreased before electroplating. The method is as follows:

[0044] (1) Rinse the metal parts for 3 minutes with clear water with a flow rate of 0.75m / s to obtain the first water-washed metal parts;

[0045] (2) Submerge the first water-washed metal piece in an alkaline degreasing solution with a mass concentration of 20g / L, and rotate it at a rate of 16r / min for 8min at 40°C to obtain an alkaline-washed metal piece, wherein the alkaline degreasing The raw material of the agent is "Steel Chemical Degreasing Powder HSY-307" purchased from Shenzhen Hongshengyuan Technology Co., Ltd.;

[0046] (3) Submerge the alkali-washed metal piece in an aqueous hydrochloric acid solution with a mass concentration of 10%, and rotate it for 3 minutes at a rate of 16 r / min to obtain the pickled metal piece;

[0047] (4) Use the pickling metal parts as the cathode, the electro-galvanized sheet as the ano...

Embodiment 2

[0052] The metal parts made of carbon steel provided by Xiongxin Electroplating Factory are degreased before electroplating. The method is as follows:

[0053] (1) Rinse the metal piece with clear water of 0.75m / s for 4 minutes to obtain the first water-washed metal piece;

[0054] (2) Submerge the first water-washed metal piece in an alkaline degreasing solution with a mass concentration of 25g / L, and rotate it at a rate of 17r / min for 9min at 45°C to obtain an alkaline-washed metal piece, wherein the alkaline degreasing The raw material of the solution is "Steel Chemical Degreasing Powder HSY-307" purchased from Shenzhen Hongshengyuan Technology Co., Ltd.;

[0055] (3) Submerge the alkali-washed metal piece in an aqueous hydrochloric acid solution with a mass concentration of 12%, and rotate it for 4 minutes at a rate of 17 r / min to obtain the pickled metal piece;

[0056] (4) Use the pickled metal parts as the cathode, use the electro-galvanized sheet as the anode, and car...

Embodiment 3

[0061] The metal parts made of carbon steel provided by Xiongxin Electroplating Factory are degreased before electroplating. The method is as follows:

[0062] (1) Rinse the metal parts for 3-5min with clear water with a flow rate of 0.75m / s to obtain the first water-washed metal parts;

[0063] (2) Submerge the first water-washed metal piece in an alkaline degreasing solution with a mass concentration of 30g / L, and rotate it at a rate of 18r / min for 10min at 50°C to obtain an alkaline-washed metal piece, wherein the alkaline degreasing The raw material of the solution is "Steel Chemical Degreasing Powder HSY-307" purchased from Shenzhen Hongshengyuan Technology Co., Ltd.;

[0064] (3) Submerge the alkali-washed metal piece in an aqueous hydrochloric acid solution with a mass concentration of 15%, and rotate it for 5 minutes at a rate of 18 r / min to obtain the pickled metal piece;

[0065] (4) Use the pickling metal parts as the cathode, the electro-galvanized sheet as the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com