Preparation method of high-resilience biodegradable polyester micro-foamed profiled bar

A technology of degrading polyester and high resilience is applied in the field of biodegradable polyester materials, which can solve the problem that the thermal stability of beads and the open porosity affect the water vapor forming ability of PBAT foam particles, and it is difficult to meet the requirements of high elastic foam materials. Application fields, poor mechanical properties of the molded body, etc., to achieve the effect of improving the secondary setting ability, high rebound rate, and improving elasticity and other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a high-resilience biodegradable polyester foam profile, comprising the following steps:

[0022] S1. After mixing PBAT resin, nucleating agent and chain extender, extrude and pelletize to obtain PBAT modified material; the chain extender is one or more of trifunctional epoxy compounds and tetrafunctional epoxy compounds kind;

[0023] S2. The PBAT modified material is made into a PBAT sheet, then saturated with a high-pressure fluid, and quickly released for foaming to obtain a PBAT foamed sheet;

[0024] S3. Heat-treating the PBAT foamed sheet through a mold to obtain a PBAT foamed profile.

[0025] Through the method of the invention, a biodegradable polyester foam profile with low density, good mechanical properties, high rebound rate and low compression set can be prepared, which is beneficial to the application in the field of high elastic foam materials.

[0026] In order to achieve the above purpose, in the embodime...

Embodiment 1

[0040] With 95wt% PBAT particles (melt index is 3.5g / 10min), 4.5wt% talcum powder nucleating agent, 0.2wt% 3 functional group epoxy (chain extender ADR4400), 0.3wt% antioxidant AT-10 Mix, obtain the modified PBAT particle that melt index is 1.0g / 10min through twin-screw pelletizing; With described modified PBAT particle injection molding, obtain the PBAT sheet material that thickness is 5mm; Put this PBAT sheet material into pressure and be 15MPa, temperature is CO at 105°C 2 Saturation in the fluid for 60 minutes, after rapid pressure relief (the pressure relief rate is about 15MPa / s, the same as the following examples), foam to obtain a PBAT foam sheet; put the PBAT foam sheet into a shoe material mold with a temperature of 160 degrees , molded for 3min, and obtained PBAT foamed shoe material through water cooling and rapid cooling, and the thickness of the foamed shoe material is 20mm (the following examples are the same).

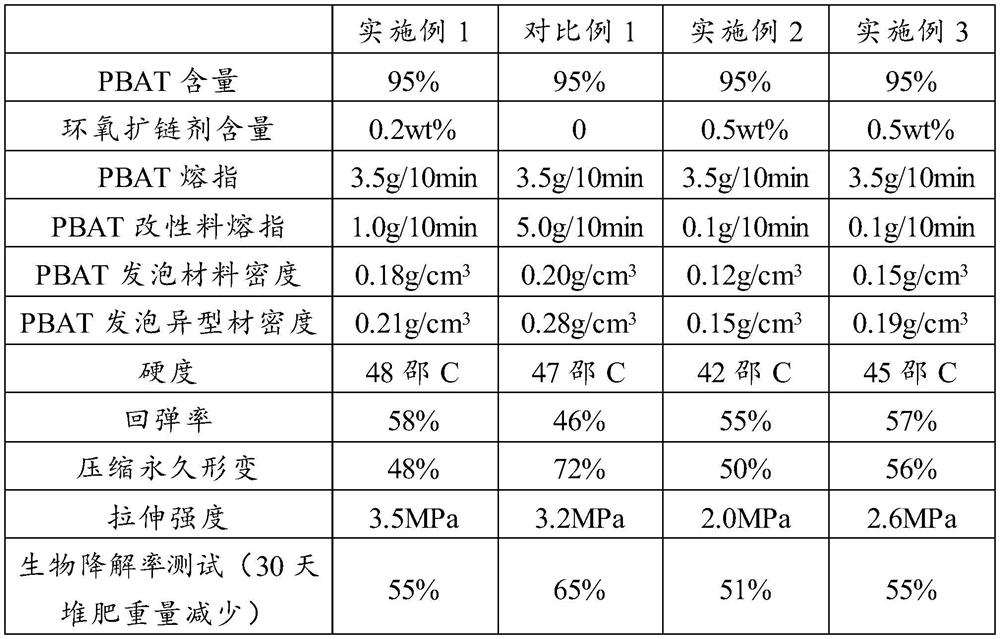

[0041] The test results are shown in Table 1: th...

Embodiment 2

[0046] The PBAT particle (melt index is 3.5g / 10min) of 95wt%, the talcum powder nucleating agent of 4.2wt%, the 3 functional group epoxy chain extender ADR4400 of 0.5wt%, the antioxidant AT-10 of 0.3wt% mix, The modified PBAT pellets with a melting index of 0.2g / 10min were obtained by twin-screw pelletizing; the modified PBAT pellets were injected to obtain a PBAT sheet with a thickness of 5mm; the PBAT sheet was placed in a pressure of 20MPa and a temperature of 110°C CO 2 Saturation in the fluid for 60 minutes, rapid pressure relief, foaming to obtain PBAT foamed sheet; put the PBAT foamed sheet into a shoe material mold at a temperature of 170 degrees, mold for 3 minutes, and rapidly cool to obtain PBAT foamed shoe material.

[0047] The test results are shown in Table 1: the density of the PBAT foam board is 0.12g / cm 3 , the density of PBAT foam profile is 0.15g / cm 3 , The hardness of the PBAT foam profile is 42 Shore C, the rebound rate is 55%, the compression set is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com