A kind of ceramic matrix composite heat-resistant plate and preparation method thereof

A composite material and heat-resistant plate technology, applied in the field of heat-resistant plates, can solve the problems of the strength reduction of metal support structures and other structural systems, the easy entry of flames into through holes, and the heat transfer of screws or bolts. The effect of slow heat rate and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

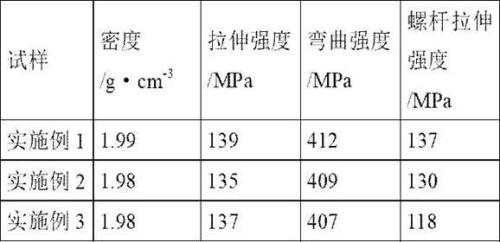

Embodiment 1

[0053] A ceramic matrix composite heat-resistant plate, the heat-resistant plate is provided with a through hole, the through-hole is an inverted convex shape, that is, the through-hole includes two parts, the first part is the part with a large diameter near the front of the heat-resistant plate , The second part is a part with a small diameter close to the back of the heat-resistant plate; a bolt is pierced through the through hole, and the head of the bolt is an inverted convex shape consistent with the shape and size of the through hole; The screw penetrates through the through hole; the gap between the through hole and the bolt is filled with a ceramic matrix made of nanofiber-containing ceramic precursor slurry.

[0054] The preparation method of the above-mentioned ceramic matrix composite heat-resistant plate, the preparation method comprises the following steps:

[0055] (1) Preparation of preforms: The heat-resistant board fiber preforms and bolt fiber preforms were ...

Embodiment 2

[0070]A ceramic matrix composite heat-resistant plate, the heat-resistant plate is provided with a through hole, the through-hole is an inverted convex shape, that is, the through-hole includes two parts, the first part is the part with a large diameter near the front of the heat-resistant plate , The second part is a small diameter part close to the back of the heat-resistant plate; the through hole is provided with a bolt; the screw rod of the bolt passes through the through hole; the head of the bolt sinks, that is, the surface of the head of the bolt There is a distance of 2mm from the front surface of the heat-resistant plate; the head of the bolt is in the same shape as the through hole, the diameter of the head is the same as the inner diameter of the through hole, and the length of the head is less than the length of the through hole by 2mm. The gap between the gaps is filled with a ceramic matrix made of nanofiber-containing ceramic precursor slurry; the space between ...

Embodiment 3

[0090] A ceramic matrix composite heat-resistant plate, the heat-resistant plate is provided with a through hole, the through-hole is an inverted convex shape, that is, the through-hole includes two parts, the first part is the part with a large diameter near the front of the heat-resistant plate , The second part is a small diameter part close to the back of the heat-resistant plate; the through hole is provided with a bolt; the screw rod of the bolt passes through the through hole; the head of the bolt sinks, that is, the surface of the head of the bolt There is a distance of 4mm from the front surface of the heat-resistant plate; the shape of the head of the bolt is the same as that of the first part of the through hole, the diameter of the head is the same as the inner diameter of the first part, the length of the head is 4mm less than the length of the first part, and the screw of the bolt The diameter is the same as the inner diameter of the second part; the gap between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com