Low-noise operation control method of ship cooling system based on real-time monitoring

A technology for cooling systems and ships, which is applied to ships and other fields, and can solve problems such as matching adaptability, difficulty in evaluating the hydraulic and vibration and noise characteristics of cooling pipeline systems, and the impact and limitations of equipment components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

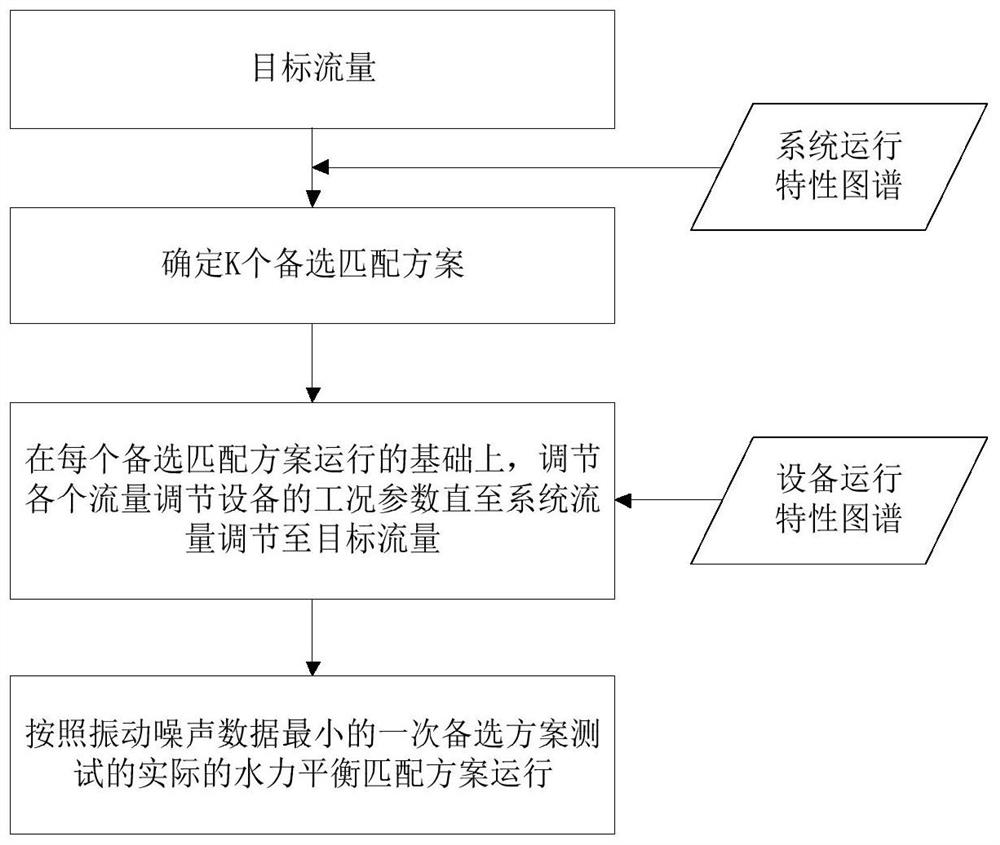

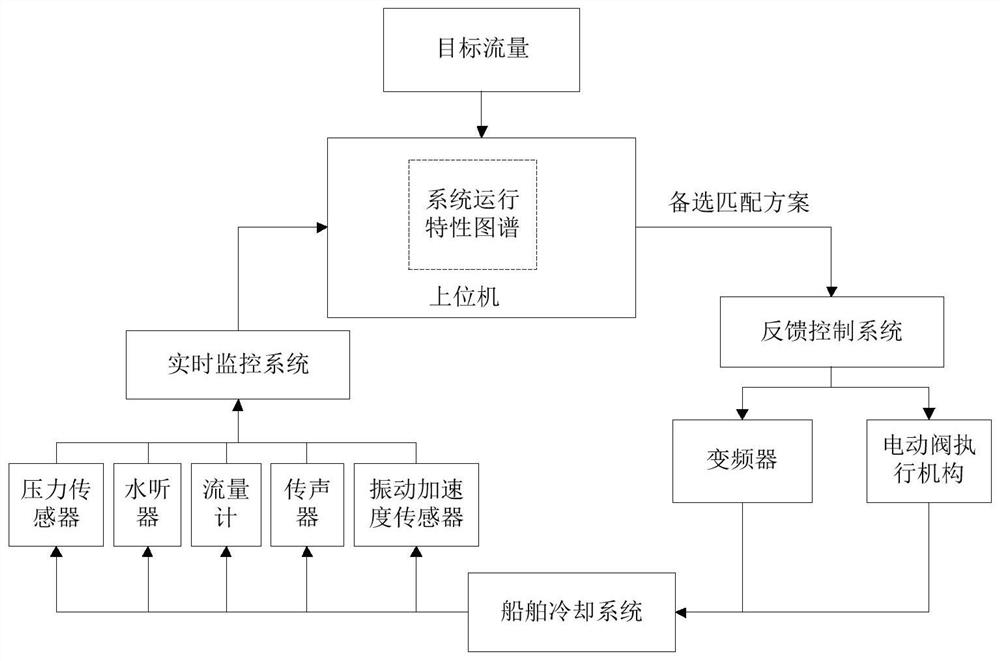

[0018] This application discloses a low-noise operation control method for a ship cooling system based on real-time monitoring, please refer to figure 1 Shown in the flow chart, the method comprises the steps:

[0019] Step S1, determining the system operating characteristic map corresponding to the cooling system of the ship.

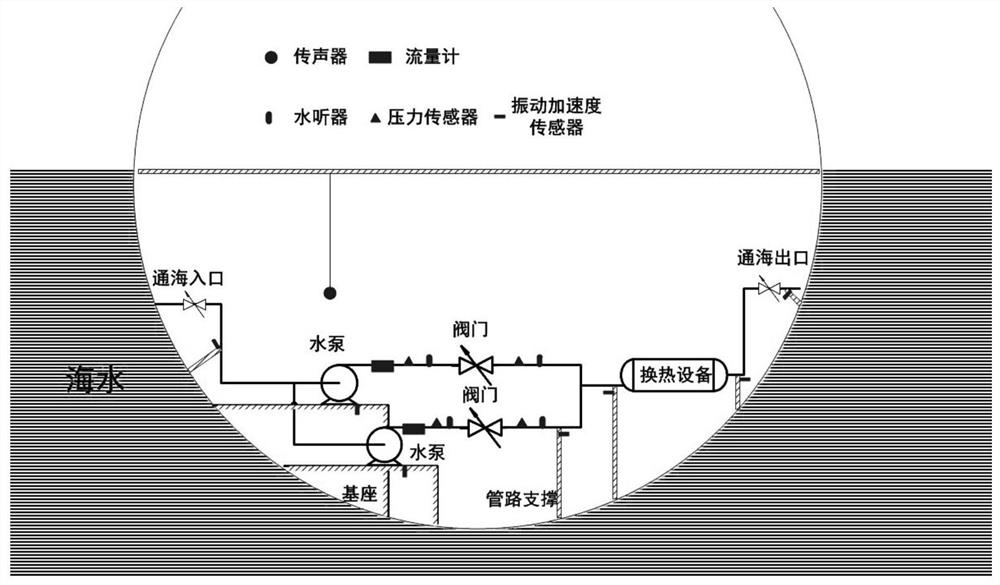

[0020] The system operation characteristic map stores sample operation data groups of the ship cooling system in different operation states, and the sample operation data groups corresponding to each operation state at least include the system flow rate, hydraulic balance matching scheme and vibration of the ship cooling system in the operation state. The noise data and the sample operation data group cover the entire range of the system flow of the ship cooling system, and the hydraulic balance matching scheme incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com