Method for detecting plate piece warping deformation and equipment for realizing method

A technology for detecting components and boards, which is applied in the direction of measuring devices, instruments, sorting, etc., can solve the problems of low accuracy of large-scale detection, failure to detect the central area, and low sampling rate of sampling methods, so as to save detection devices and control device cost, save detection time, and reduce the effect of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

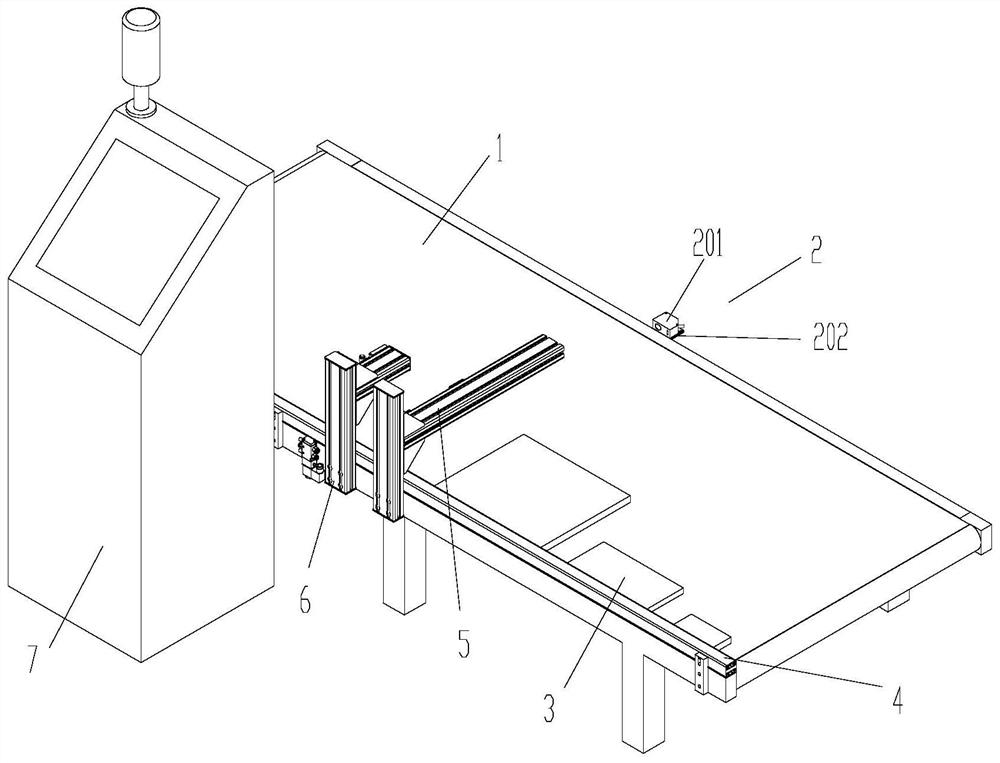

[0050] This embodiment is a method for detecting the warping deformation of the board, which is to transmit the board at a constant speed; during the uniform speed transmission of the board, the top detection component located above the board detects the distance between the board and the board in the height direction Change to get the degree of warpage of the plate; according to the degree of warpage to determine whether the warpage of the plate is qualified.

[0051] The method of the present invention can realize automatic detection of warpage and deformation of plates, save a lot of labor costs and improve detection efficiency, can effectively avoid the situation of subjective errors in manual detection, and improve detection accuracy; it can realize automatic full inspection of large batches of plates, It avoids the missed inspection of unqualified boards caused by random inspection, strengthens the processing consistency of subsequent processes and improves product qualit...

Embodiment 2

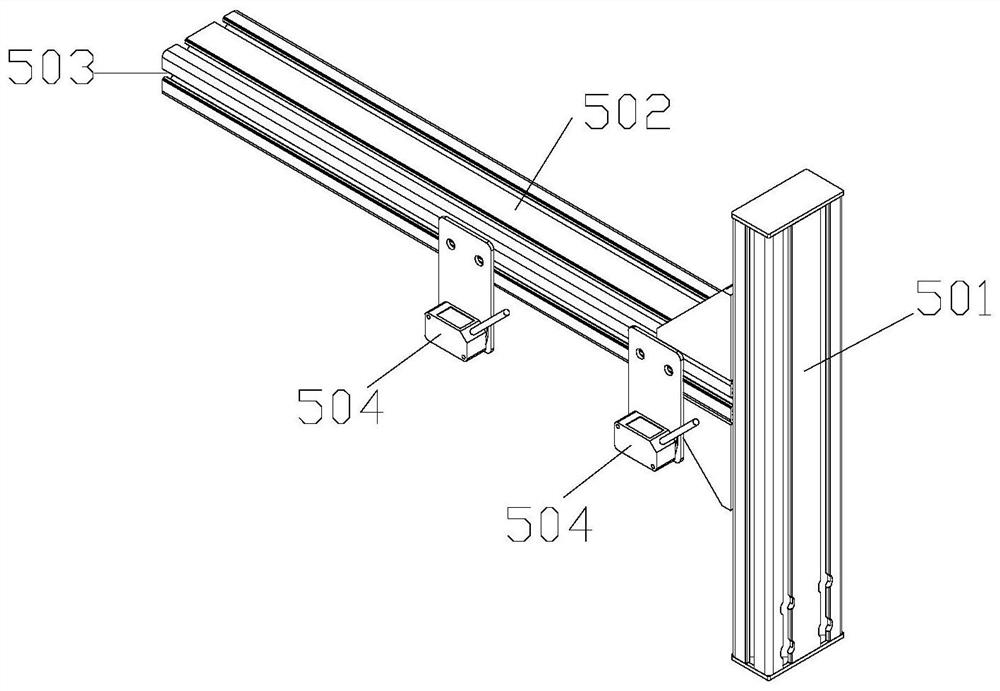

[0077] This embodiment is a device for detecting the warping deformation of boards. The difference from Embodiment 1 is that the top detection component includes a moving top distance measuring sensor module and a fixed top distance measuring sensor module, or only includes a movable top distance measuring sensor module. The moving top ranging sensing module does not include the stationary top ranging sensing module.

[0078] The movable top ranging sensing module is connected with the beam through the horizontal moving device, so as to realize the horizontal movement of the movable top ranging sensing module perpendicular to the conveying direction. The horizontal moving device can adopt existing technology, such as lead screw and nut mechanism, electric slide table and so on.

[0079] The control device is also used to set the width detection component before the top detection component according to the size of the board (the size of the board can be the size of the board ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com