Centrifugal device for processing stem cell exosome

A centrifuge device and exosome technology, applied in centrifuges and other directions, can solve the problems of inability to centrifuge control, waste of manpower and material resources, and inability to separate exosomes, and achieve the effect of improving efficiency and improving centrifugal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

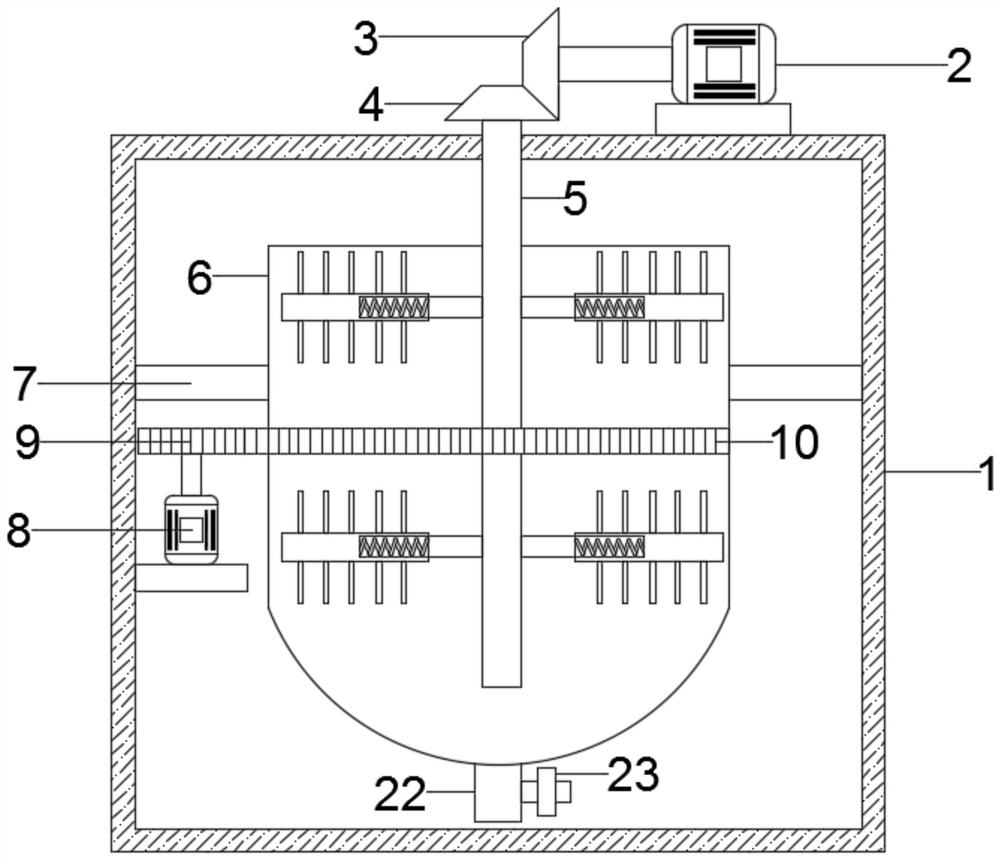

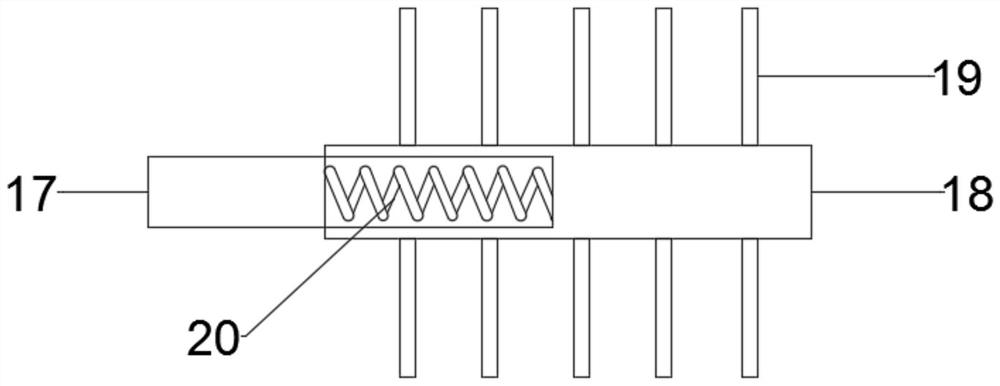

[0021] see Figure 1~2 , in an embodiment of the present invention, a centrifugal device for stem cell exosome processing, comprising a device main body 1, a side wall of the device main body 1 is fixedly provided with a mounting plate, and a second motor 8 is fixedly provided on the mounting plate , the rotating part of the second motor 8 is fixedly connected with a gear 9, and a bracket 7 is fixedly arranged in the main body 1 of the device, and a fixed cylinder 6 is rotatably arranged on the bracket 7, and the outer surface of the fixed cylinder 6 is fixedly arranged There is a ring gear 10, the ring gear 10 is meshed with the gear 9, the bottom of the fixed cylinder 6 is provided with a discharge pipe 22, and the discharge pipe 22 is fixedly provided with a control valve 23;

[0022] Further, the top of the main body 1 of the device is fixedly provided with a first motor 2, the rotating part of the first motor 2 is fixedly provided with a first bevel gear 3, and a second b...

Embodiment 2

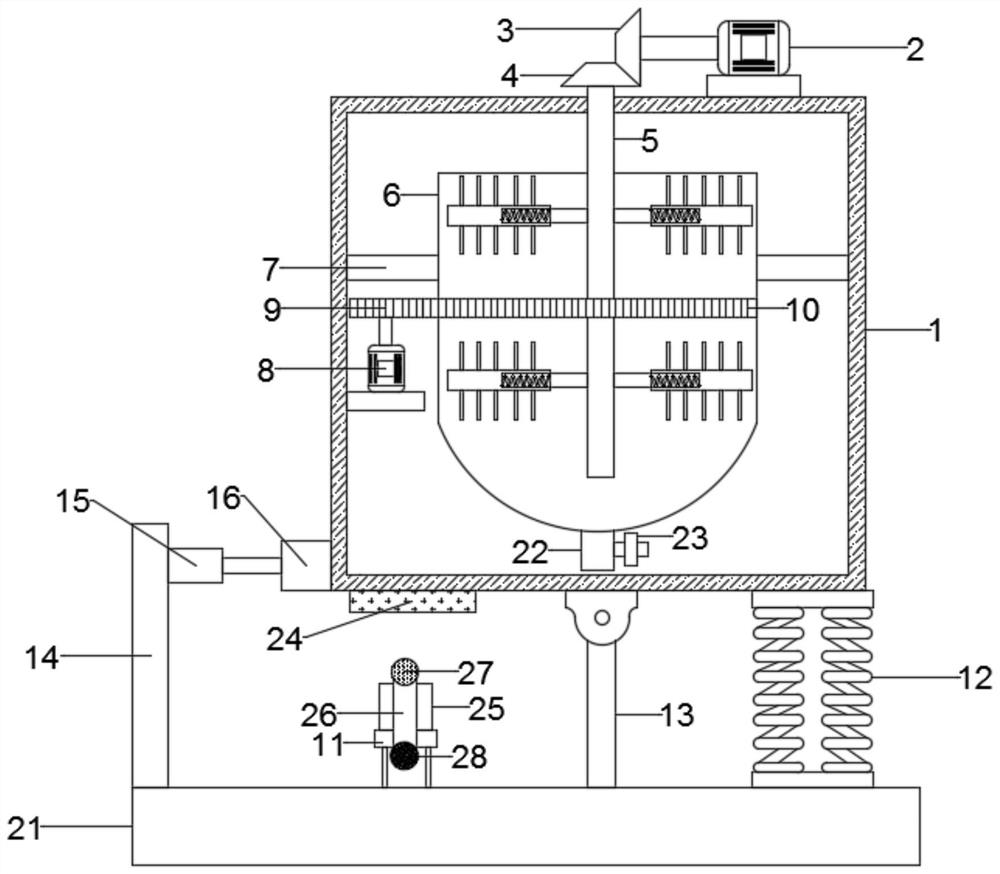

[0024] see image 3 , The difference between this embodiment and Embodiment 1 is that it also includes a shaking mechanism, a support plate 21 is fixedly arranged below the device main body 1, and a fixed plate 14 is fixedly arranged on the support plate 21, and the fixed plate 14 The top is fixedly provided with an electric telescopic rod 15, and the bottom of the device main body 1 is fixedly provided with a fixed block 16 at a position corresponding to the electric telescopic rod 15, and the end of the telescopic rod 15 of the electric telescopic rod 15 is inserted into the fixed block 16. The bottom of the main body 1 of the device is fixedly provided with a magnetic plate 24, and a plurality of support rods are evenly distributed on the position corresponding to the magnetic plate 24 on the support plate 21. The end of the support rod away from the support plate 21 is fixedly provided with a mounting base 11, so that A third motor 25 is fixedly installed on the mounting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com