Method for removing colloid in xylitol solution by utilizing carbon dioxide gas

A carbon dioxide and xylitol technology, applied in the field of xylitol production, can solve the problems affecting the purity and quality of xylitol crystals, unsatisfactory removal of impurities, and limited application space, etc., to achieve obvious removal of impurities, crystal growth and Create fast and cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for removing colloids in xylitol solution with carbon dioxide gas, comprising the following steps:

[0021] (1) getting calcium oxide dissolved in water to make massfraction is 20% milk of lime;

[0022] (2) Take a xylitol solution with a concentration of 30% and heat it at 60° C. for 2 hours, then add the milk of lime prepared above to adjust the pH of the xylitol solution to 9.5 to obtain a mixed solution a;

[0023] (3) Pass CO into the mixed solution a 2 Gas, stirred at a stirring speed of 30r / min for 6h to make it fully dissolved until the pH value of the mixed solution a was 6.5, stop feeding CO 2 gas, then stand still for 25 minutes, filter to obtain the precipitate, and centrifuge the precipitate at a speed of 6000r / min for 35 minutes to obtain a xylitol solution.

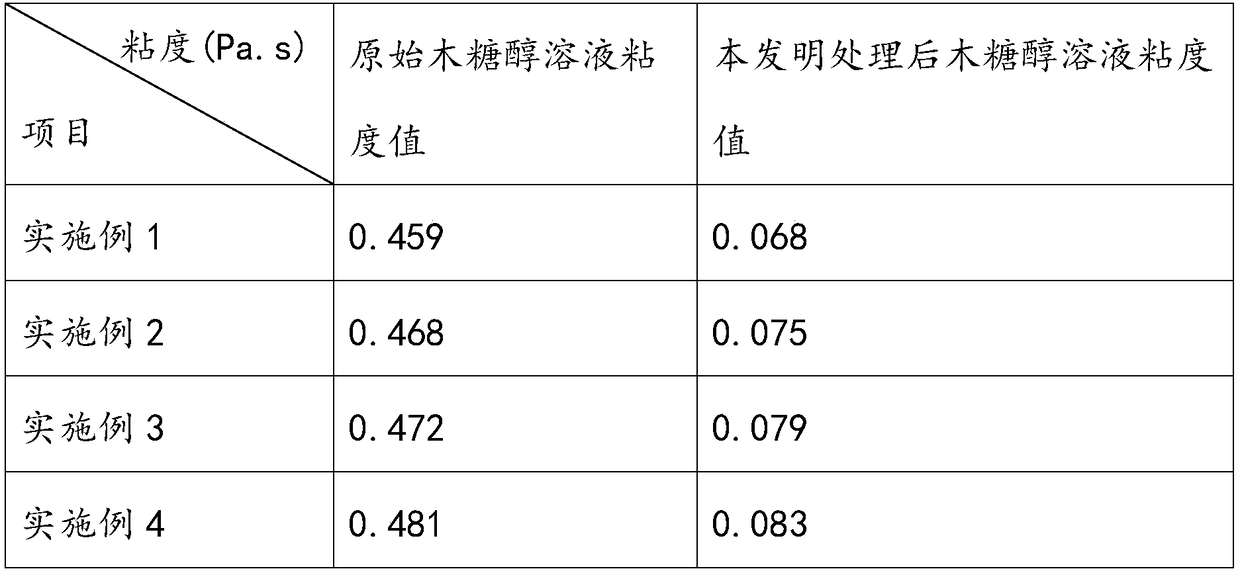

[0024] (4) Detect the viscosity of the original xylitol solution and the xylitol solution prepared above in Table 1.

Embodiment 2

[0026] A method for removing colloids in xylitol solution with carbon dioxide gas, comprising the following steps:

[0027] (1) getting calcium oxide dissolved in water to make massfraction is 25% milk of lime;

[0028] (2) Take a xylitol solution with a concentration of 35% and heat it at 65° C. for 1.5 h, then add the milk of lime prepared above to adjust the pH value of the xylitol solution to 11 to obtain a mixed solution a;

[0029] (3) Pass CO into the mixed solution a 2 Gas, stirred at a stirring speed of 40r / min for 5h to make it fully dissolved until the pH value of the mixed solution a was 7.5 and stopped feeding CO 2 gas, then stand still for 40 minutes, filter to obtain the precipitate, and centrifuge the precipitate at a speed of 8000r / min for 20 minutes to obtain a xylitol solution.

[0030] (4) Detect the viscosity of the original xylitol solution and the xylitol solution prepared above in Table 1.

Embodiment 3

[0032] A method for removing colloids in xylitol solution with carbon dioxide gas, comprising the following steps:

[0033] (1) getting calcium oxide dissolved in water to make massfraction is 30% milk of lime;

[0034] (2) Take a xylitol solution with a concentration of 40% and heat it at 70° C. for 1.2 h, then add the milk of lime prepared above to adjust the pH value of the xylitol solution to 10 to obtain a mixed solution a;

[0035] (3) Pass CO into the mixed solution a 2 Gas, stirred at a stirring speed of 45r / min for 4.5h to make it fully dissolved until the pH value of the mixed solution a was 7, stop feeding CO 2 gas, then stand still for 30 minutes, filter to obtain a precipitate, and centrifuge the precipitate at a speed of 7000r / min for 30 minutes to obtain a xylitol solution.

[0036] (4) Detect the viscosity of the original xylitol solution and the xylitol solution prepared above in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com