Catalyst for preparing diphenyl carbonate as well as preparation method and application thereof

A technology for diphenyl carbonate and dimethyl carbonate, which is applied to the catalyst for preparing diphenyl carbonate and the field of preparation thereof, can solve the problem that the catalyst is not easily deactivated, the active component is lost, the activity of the heterogeneous catalyst, and the selectivity is low. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

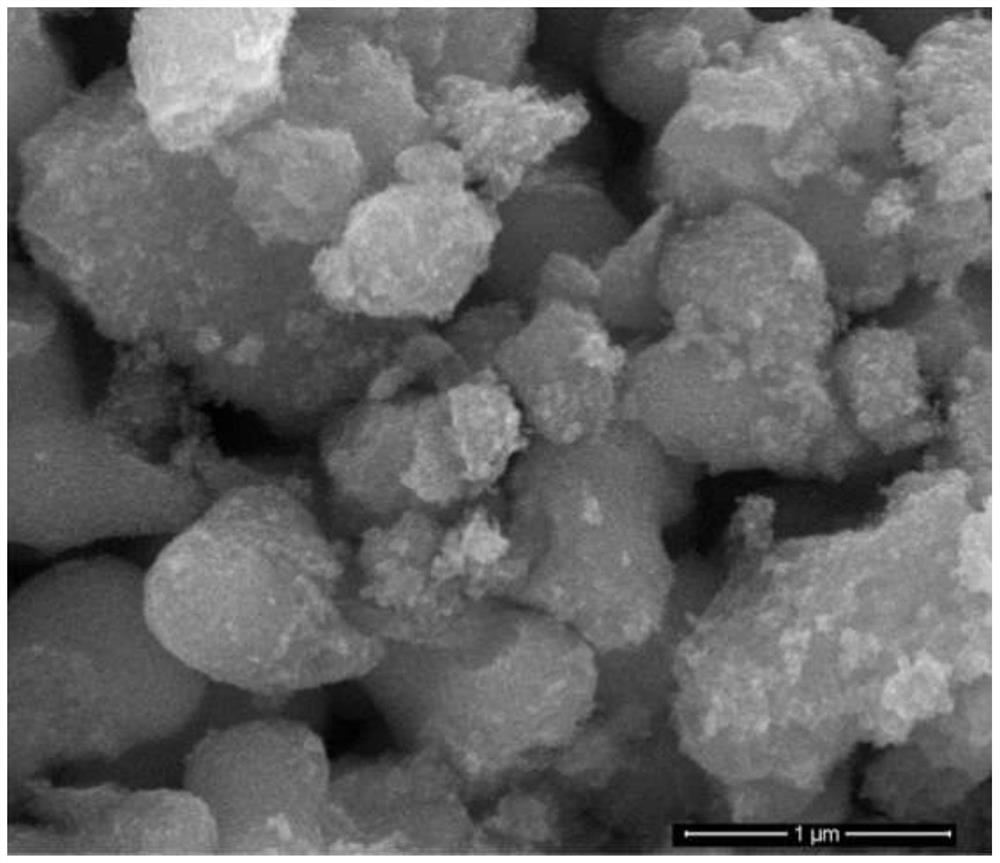

[0046] Dissolve 0.53 g of glucose in 100 mL of water, stir, add dropwise sulfuric acid to adjust the pH to 1, and add 20 g of tetrabutyl titanate to prepare a precursor solution. Put the precursor solution into a high-pressure hydrothermal kettle, conduct hydrothermal crystallization treatment at 160° C. for 24 hours, cool, filter, wash with water, and dry to obtain a catalyst intermediate. The catalyst intermediate was calcined at 200° C. for 2 h under nitrogen atmosphere to obtain catalyst C1.

[0047] It was measured that the particle size of the titanium dioxide particles in the catalyst C1 was 1000 nm, and the thickness of the carbon layer was 5 nm.

Embodiment 2

[0049] Dissolve 1.1 g of glucose in 100 mL of water, stir, add dropwise hydrochloric acid to adjust the pH to 2, and add 20 g of tetrabutyl titanate to prepare a precursor solution. Put the precursor solution into a high-pressure hydrothermal kettle, conduct hydrothermal crystallization treatment at 170° C. for 24 hours, cool, filter, wash with water, and dry to obtain a catalyst intermediate. The catalyst intermediate was calcined at 200° C. for 2 h under nitrogen atmosphere to obtain catalyst C2.

[0050] It is measured that the particle size of the titanium dioxide particles in the catalyst C2 is 1000 nm, and the thickness of the carbon layer is 10 nm.

Embodiment 3

[0052] 2.1 g of glucose was dissolved in 100 mL of water, stirred, hydrochloric acid was added dropwise to adjust the pH to 2, and 20 g of tetrabutyl titanate was added to prepare a precursor solution. Put the precursor solution into a high-pressure hydrothermal kettle, conduct hydrothermal crystallization treatment at 170° C. for 24 hours, cool, filter, wash with water, and dry to obtain a catalyst intermediate. The catalyst intermediate was calcined at 200° C. for 2 h under nitrogen atmosphere to obtain catalyst C3.

[0053] It was measured that the particle size of the titanium dioxide particles in the catalyst C3 was 1000 nm, and the thickness of the carbon layer was 16 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com