Volatile gas purification treatment system

A volatile gas purification treatment technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as environmental pollution, failure to meet the needs of volatile gas recovery, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

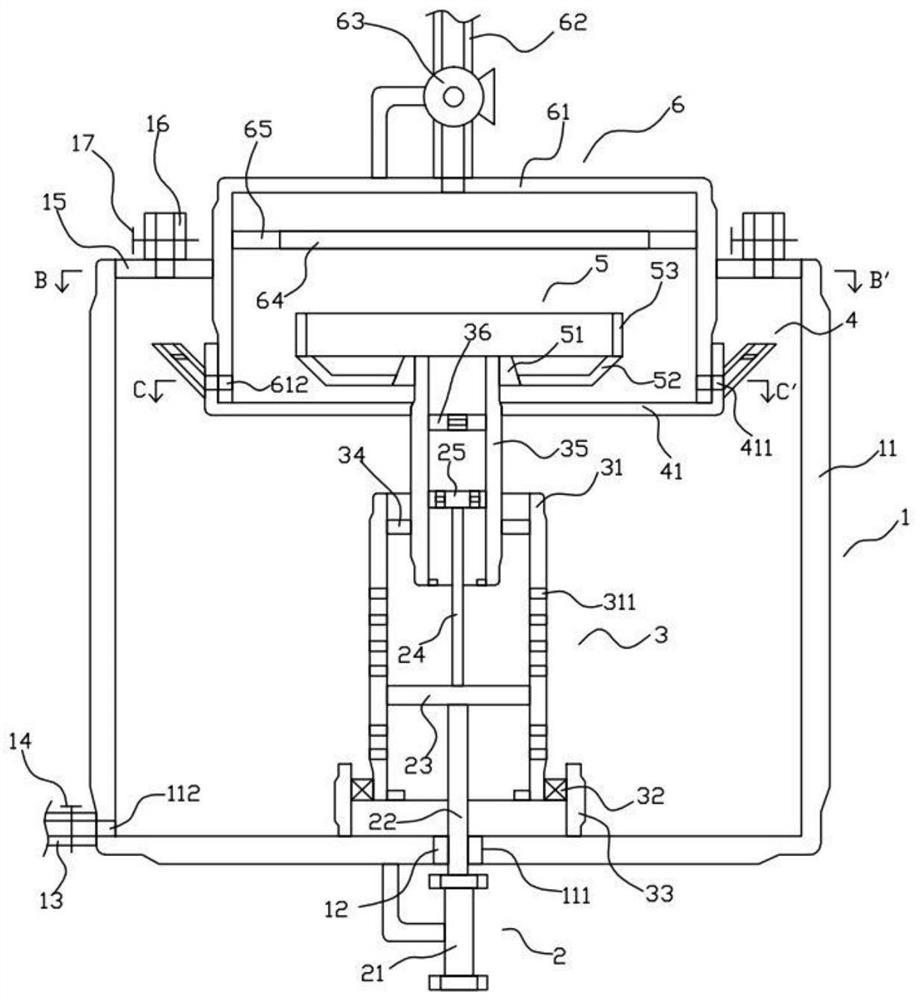

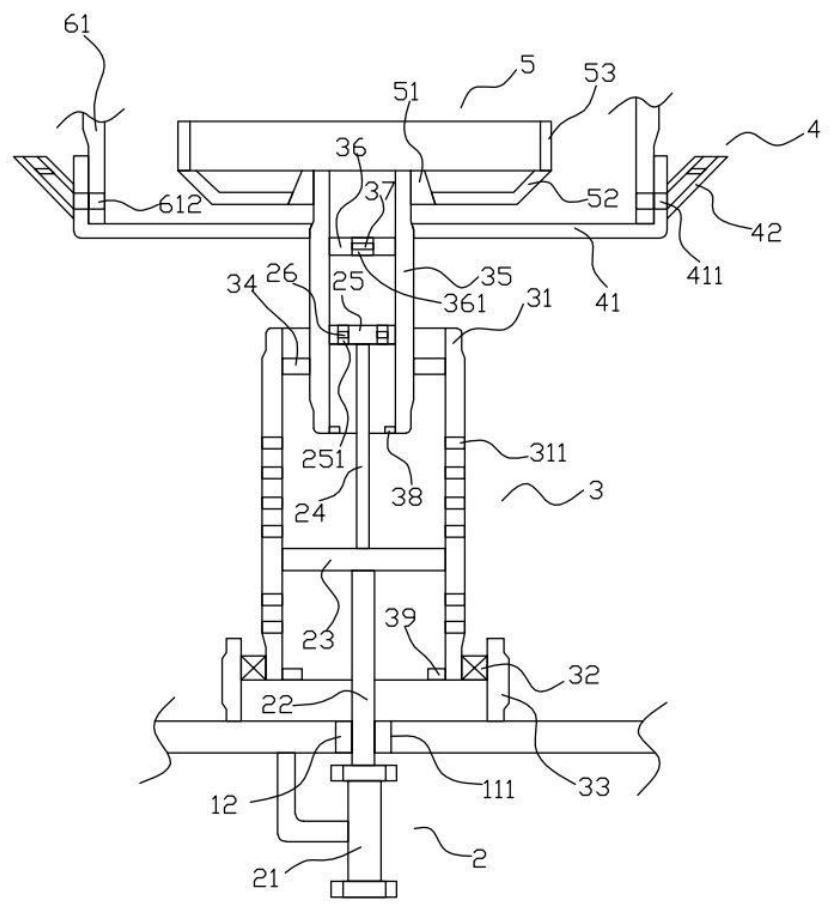

[0027] Such as Figure 1 to Figure 6 As shown, the volatile gas purification system of the present invention includes a housing structure 1, a driving structure 2 disposed on the housing structure 1, a rotating structure 3 disposed in the housing structure 1, and a rotating structure disposed on the rotating structure 3. The frame structure 4 , the spraying structure 5 arranged on the upper end of the rotating structure 3 , and the covering frame structure 6 located above the rotating structure 3 .

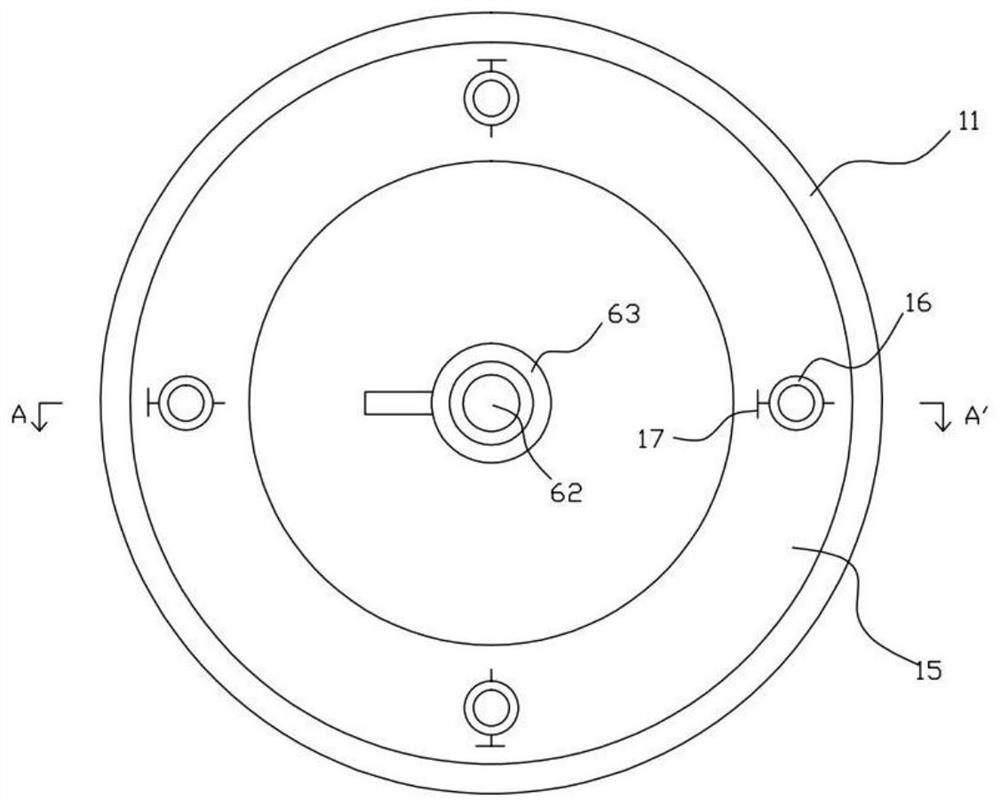

[0028] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the housing structure 1 includes a housing 11, a sealing block 12 disposed on the lower wall of the housing 11, a discharge pipe 13 disposed outside the housing 11, a first valve 14 disposed on the discharge pipe 13, and a A fixed plate 15 at the upper end of the inner cavity of the housing 11 , a plurality of exhaust pipes 16 arranged above the fixed plate 15 , and a second valve 17 arranged on the exhaust ...

Embodiment 2

[0040] Embodiment two: if Figure 7 and Figure 8 As shown, the structure of the second embodiment of the volatile gas purification treatment system of the present invention is basically the same as that of the first embodiment, the only difference being that the second embodiment of the volatile gas purification treatment system of the present invention also includes a rotating Stirring structure 7 on structure 3. The stirring structure 7 is provided with several and evenly distributed, and the stirring structure 7 includes a first spring 71, a positioning rod 72 arranged at the end of the first spring 71, an abutment rod 73 arranged at the end of the positioning rod 72, and a positioning rod 72 arranged at the end of the positioning rod 72. The moving rod 74 on the top, the stirring rod 75 arranged at both ends of the moving rod 74, the second spring 76 arranged on the moving rod 74. One end of the first spring 71 is fixedly connected to the outer peripheral surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com