Multi-stage dust collection device and dust collector

A dust collection device and dust collection technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problem of poor sealing effect of multi-stage sewage outlets, and achieve the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

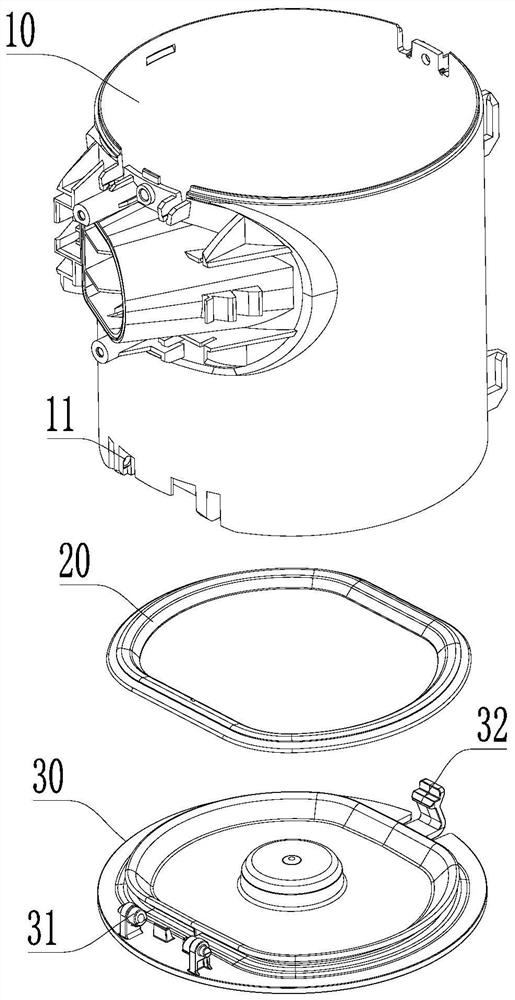

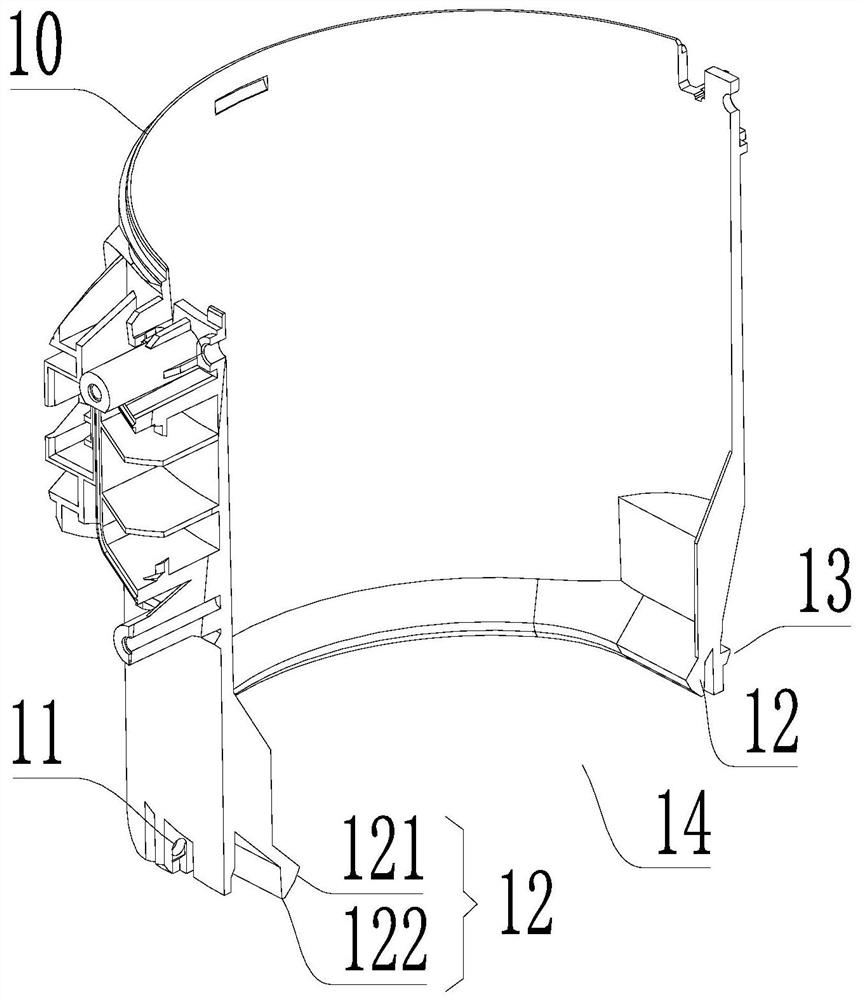

[0063] to combine Figure 1-Figure 11 As shown, the dust collection device provided in this embodiment includes:

[0064] dust cup 10;

[0065] The dust cup sewage outlet 14 is at least partly set through the dust cup 10;

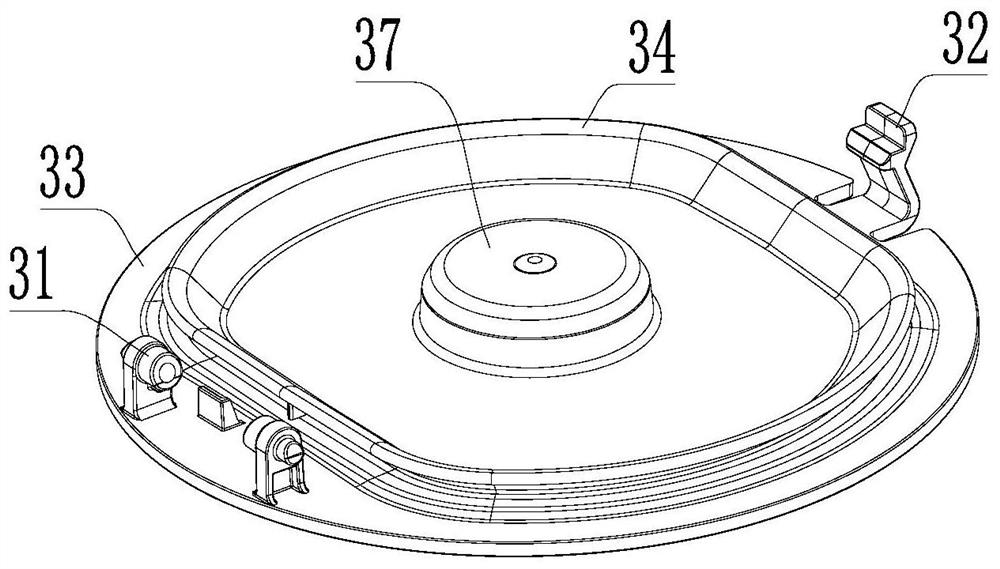

[0066] The dust cup bottom cover 30 is opened and closed on the dust cup 10. The dust cup bottom cover 30 includes the first position state of blocking the dust cup sewage outlet 14, and the opening of the dust cup sewage outlet 14. the second location status; and

[0067] The sealing ring 20 is adapted to seal the interface between the dust cup bottom cover 30 and the dust cup drain port 14 through at least two layers of sealing parts.

[0068] The dust collecting device provided in this embodiment realizes the sealing of the interface between the dust cup bottom cover 30 and the dust cup sewage outlet 14 by setting the sealing ring 20, and the sealing ring 20 is sealed by at least two layers of sealing parts, thereby improving the sealing effect. As a...

Embodiment 2

[0103] On the basis of the dust collection device provided in the first embodiment above, the number of dust collection chambers of the dust collection device can also be increased by adding a secondary dust collection unit, and while increasing the number of dust collection chambers, multiple dust collection chambers The sealing of the dust collector is also an important problem to be solved in this plan. The following takes the two-stage dust collection device as an example to describe in detail.

[0104] combine Figure 12-Figure 17 As shown, the multi-stage dust collection device provided in this embodiment includes:

[0105] dust cup 10;

[0106] The secondary dust collection unit 40 is at least partially nested inside the dust cup 10;

[0107] The dust cup sewage discharge port 14 and the secondary sewage discharge port 42 are respectively formed through the dust cup 10 and the secondary dust collection unit 40 in the same direction;

[0108] The bottom cover 30 of th...

Embodiment 3

[0135] This embodiment provides a vacuum cleaner, including: a vacuum cleaner body, and

[0136] The dust collection device and / or the multi-stage dust collection device as described above.

[0137] Preferably, the vacuum cleaner is also provided with a host machine 90, and the interior of the host machine 90 is suitable for placing a negative pressure vacuum motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com