Metering chamber component of graphite scraper flowmeter

A technology of scraper flowmeter and metering chamber, which is applied in the direction of volume measurement, movable measuring chamber, measuring capacity, etc., and can solve the problem that the cavity of the metering chamber cannot be effectively cut off, affects the accuracy of volumetric metering, and the metering chamber cannot be fully sealed and other problems to achieve the effect of avoiding back and forth shaking, improving sliding flexibility, and facilitating retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0052] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

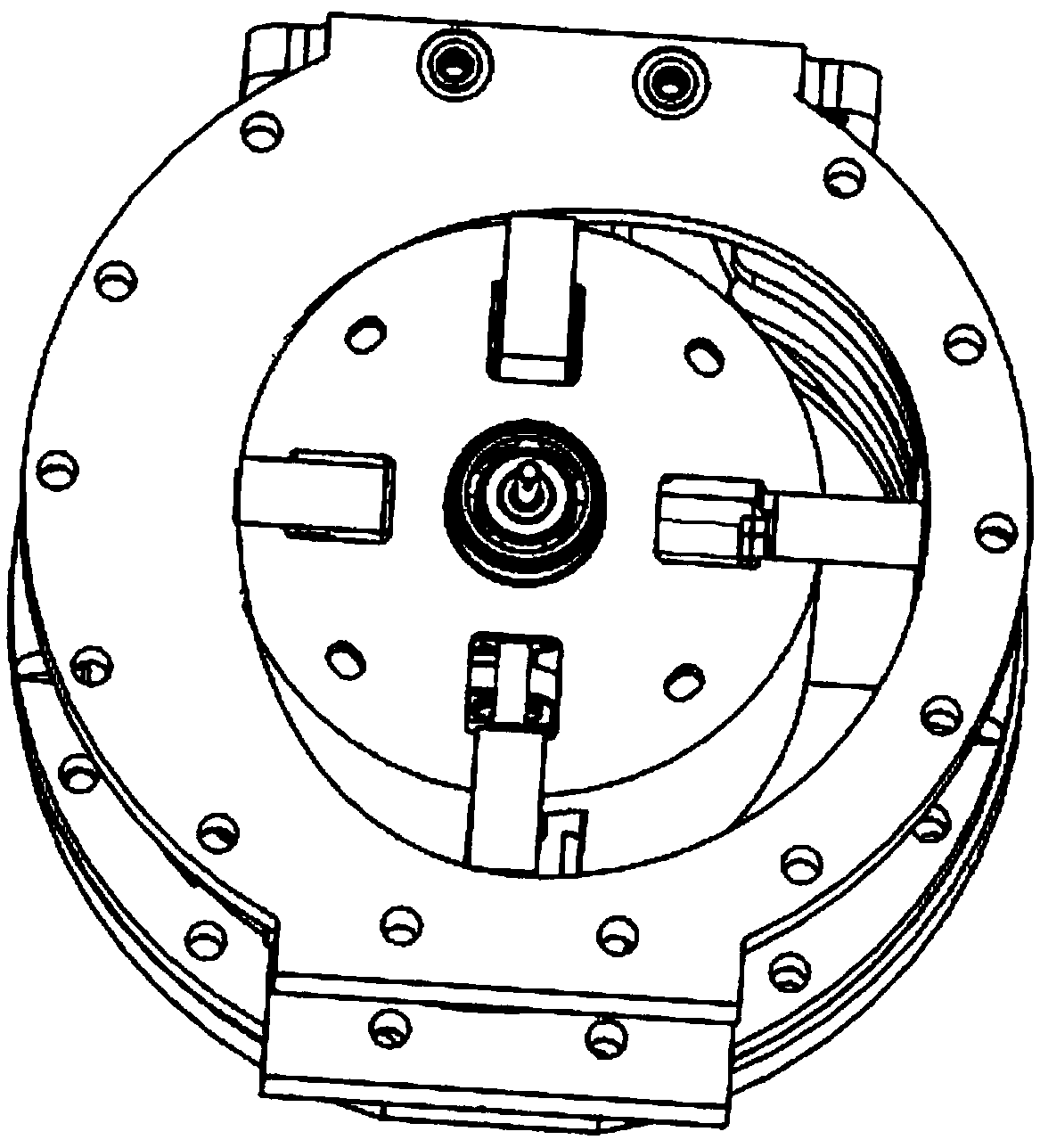

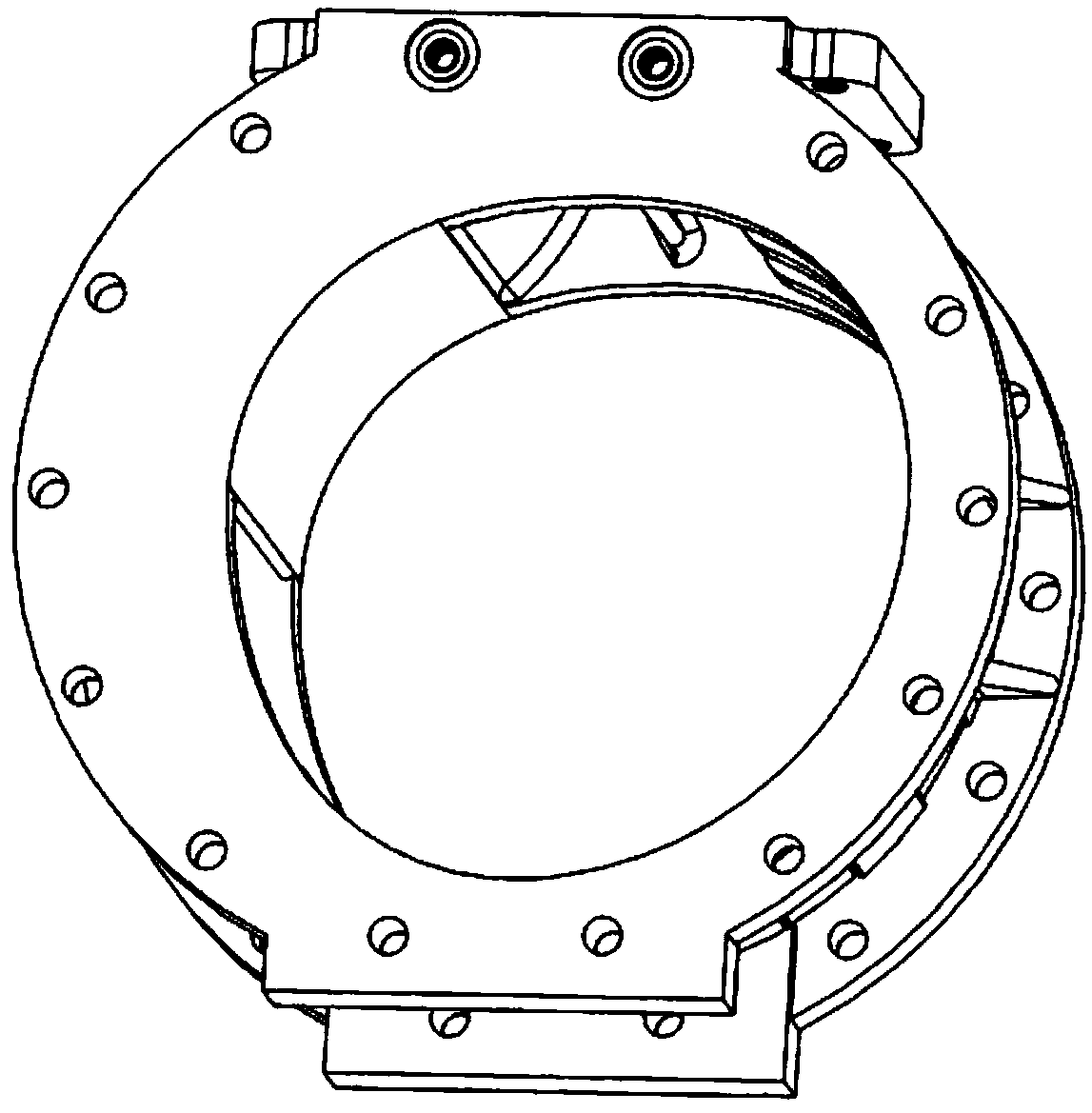

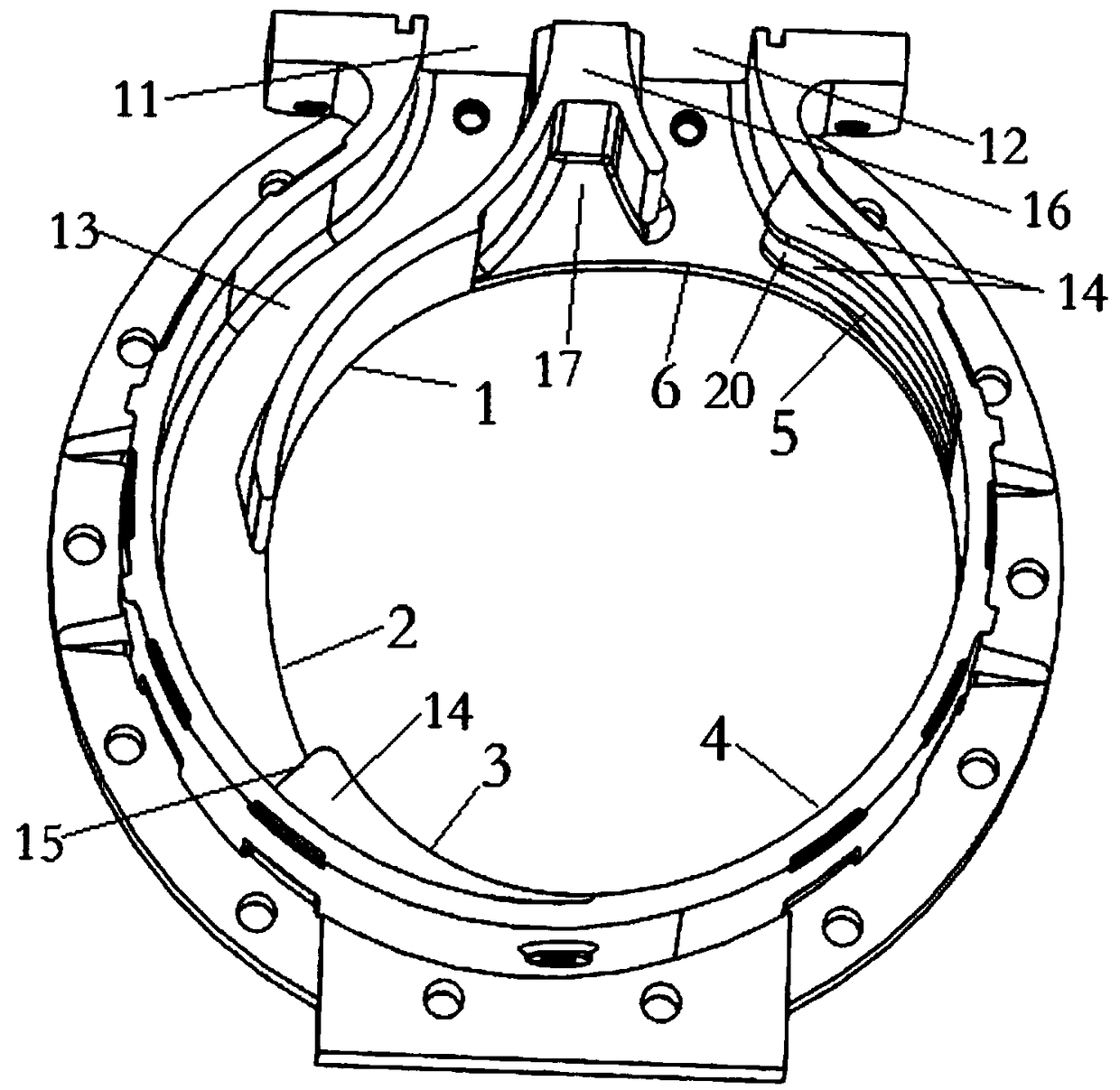

[0053] A metering chamber component of a graphite scraper flowmeter, such as figure 1 with Figure 10 As shown, it includes the metering chamber and the rotor assembly installed in the metering chamber. Among them, such as figure 2 -shown in 5, the metering chamber comprises a metering chamber cavity and an inlet 11 and an outlet 12 communicated with the metering chamber cavity respectively, and the inlet 11 and the outlet 12 are arranged on the sidewall of the metering chamber cavity; The cross-section of the body is in the shape of a cam profile, and the cam profile is surrounded by 4 curves,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com