Lifting type magnetostriction displacement transmitter

A displacement transmitter and magnetostrictive technology, applied in the direction of instruments, electromagnetic means, measuring devices, etc., can solve the real-time monitoring affecting the displacement change of the gas injection tree, the magnetic steel cannot move normally, and the condensation water is generated. To achieve the effect of reducing erosion and impact, reducing impact, reducing the generation of condensation water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

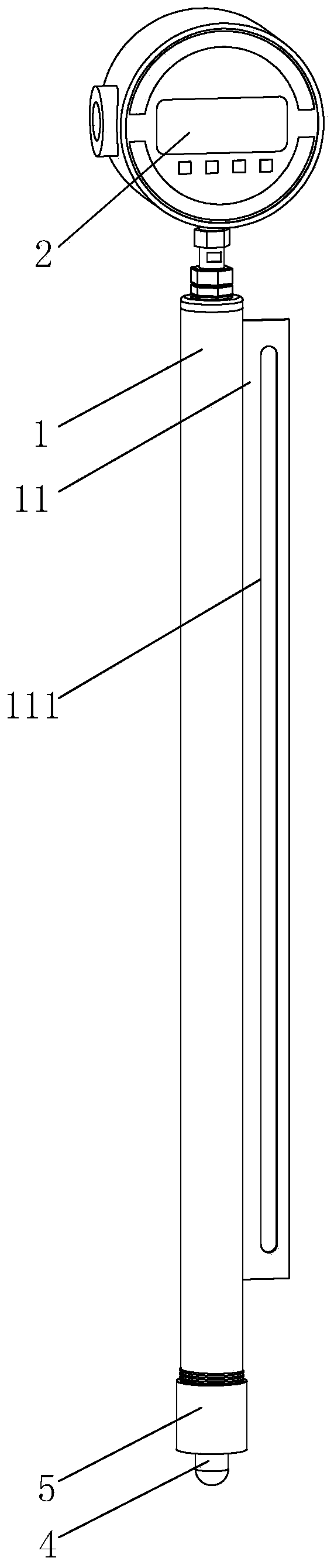

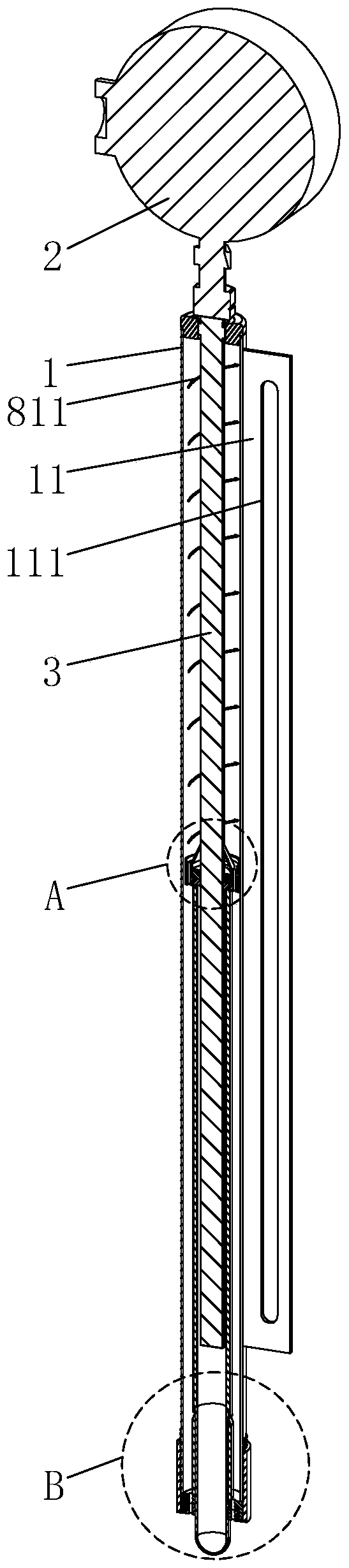

[0037] refer to figure 1 , is a lift-type magnetostrictive displacement transmitter disclosed in the present invention, comprising a magnetostrictive body 1, the magnetostrictive body 1 is placed vertically, an electronic gauge 2 is arranged on the top of the magnetostrictive body 1, and the magnetostrictive body 1 is placed vertically. The outer wall of the main body 1 is fixedly provided with a fixed bracket 11, the fixed bracket 11 is arranged along the length direction of the magnetostrictive body 1, and the fixed bracket 11 is provided with a distance-adjusting hole 111, and the distance-adjusting hole 111 is provided along the length direction of the fixed bracket 11, and the magnetostrictive The bottom of the body 1 is threadedly connected with a flat cover body 5, and a piston sleeve 4 is arranged inside the magnetostrictive body 1, and the piston sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com