Intelligent active control type high-pressure pipeline pressure pulsation damping device and method

A high-pressure pipeline and pressure pulsation technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as accidents, pipeline fatigue damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

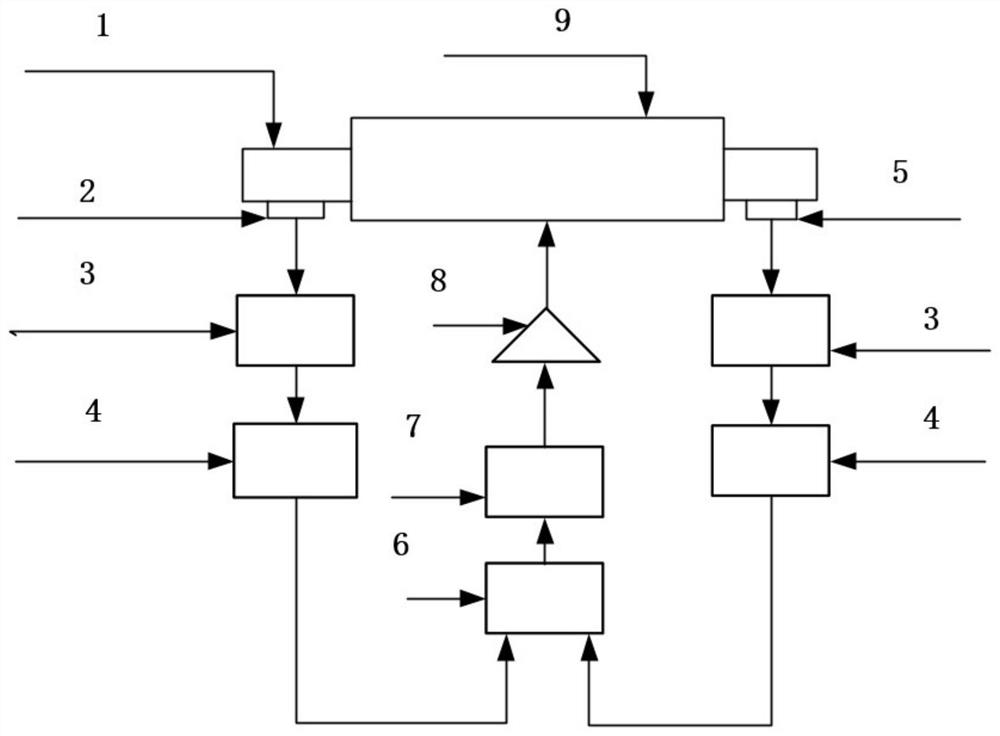

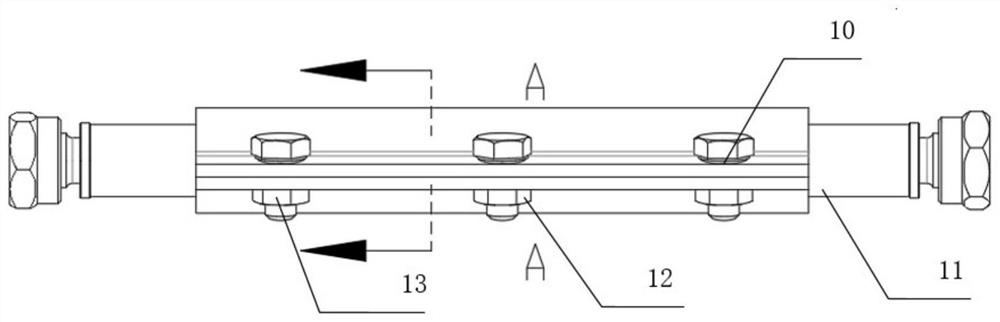

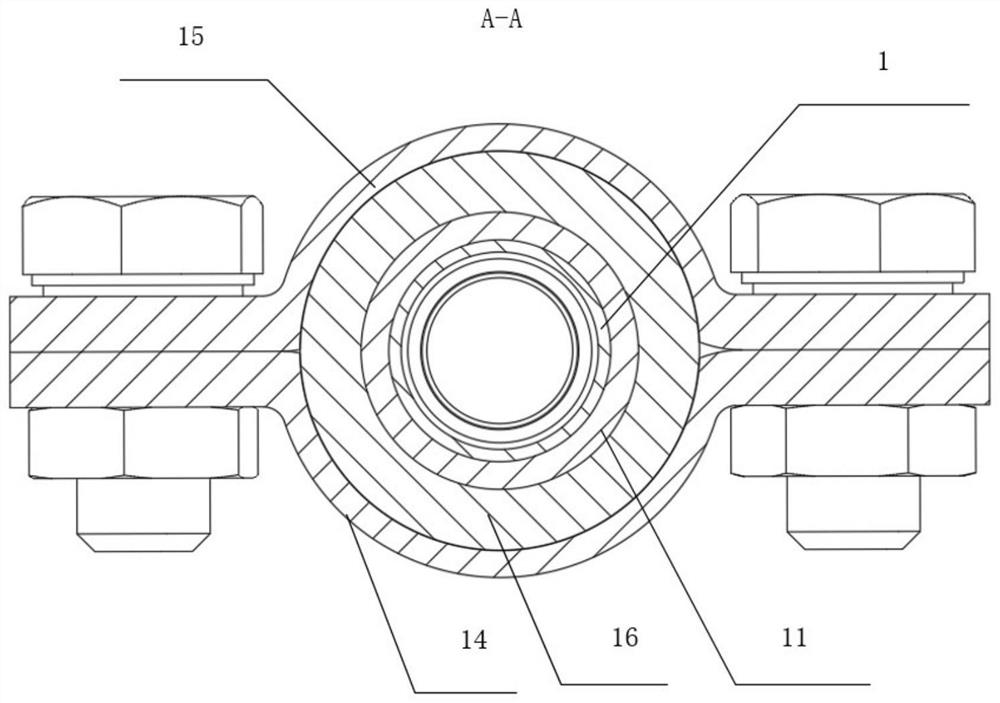

[0065] First, see figure 1 , figure 2 , image 3 , this embodiment provides an intelligent active control type high-pressure pipeline pressure pulsation damping device, the device includes: input pressure sensor 2, signal conditioning unit 3, A / D module 4, output pressure sensor 5, control unit 6, D / A module 7, intelligent active control high pressure pipeline pressure pulsation damping device 9.

[0066] The signal conditioning unit 3 includes a first signal conditioning unit 31 and a second signal conditioning unit 32 .

[0067] The A / D module 4 includes a first A / D module 41 and a second A / D module 42;

[0068] The input pressure sensor 2 is located at the entrance of the intelligent active control high-pressure line pressure pulsation dampening device 9 and connected to the input end of the first signal conditioning unit 31 .

[0069] The output end of the first signal conditioning unit 31 is connected to the input end of the first A / D module 41 .

[0070] The output...

Embodiment 2

[0091] In the second aspect, see Figure 5 , this embodiment also provides a control method based on any of the above-mentioned intelligent active control type high-pressure pipeline pressure pulsation damping devices, including:

[0092] S1. Using an input pressure sensor to obtain pressure pulsation information of a high-pressure pipeline.

[0093] S2. The information conversion device converts the vibration information into corresponding data information.

[0094] S3. The control unit obtains information on the vibration frequency, amplitude and phase of the pressure pulsation of the high-pressure pipeline according to the data information, and finally determines the vibration of the high-pressure pipeline through data processing and analysis of the pressure pulsation data and the model of the high-pressure pipeline For frequency, magnitude and phase data information, see Figure 8 . An incremental PID control algorithm is used to process the data information, a control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com