A Magnetically Suspended Quasi-Zero-Stiffness Electromagnetic Isolator with Active Negative Stiffness

A technology of quasi-zero stiffness and negative stiffness, which is applied in the field of magnetic levitation quasi-zero stiffness electromagnetic vibration isolators, can solve problems such as conflicts, and achieve the effect of expanding the working range, simple installation method, and high load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

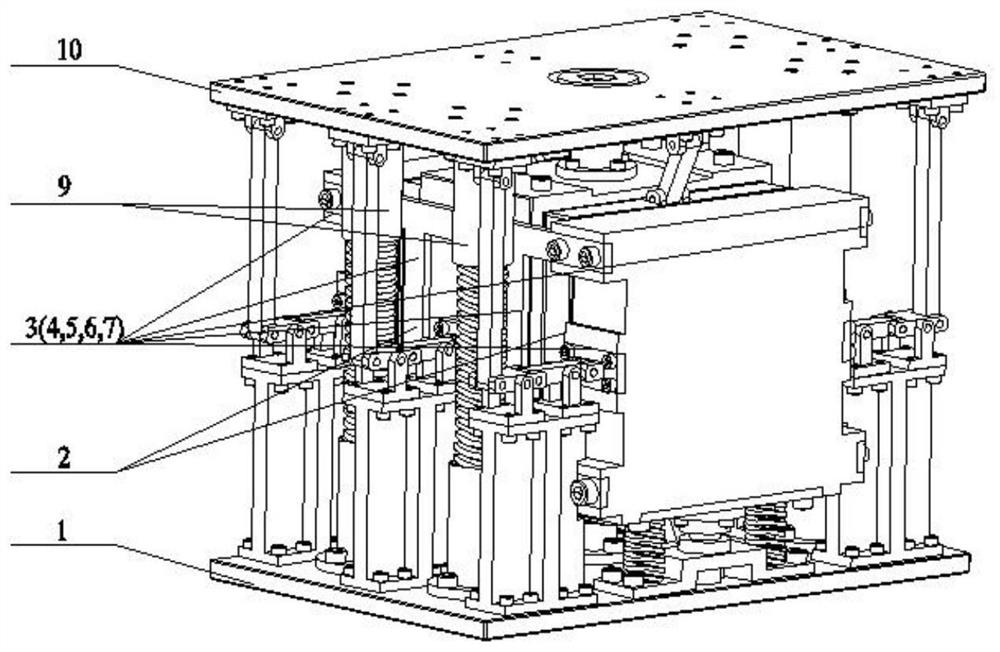

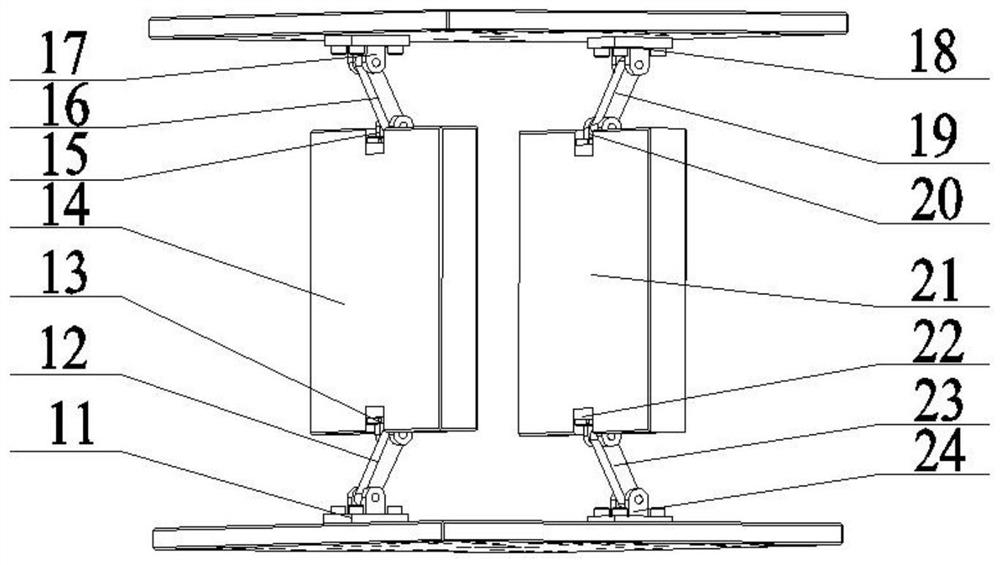

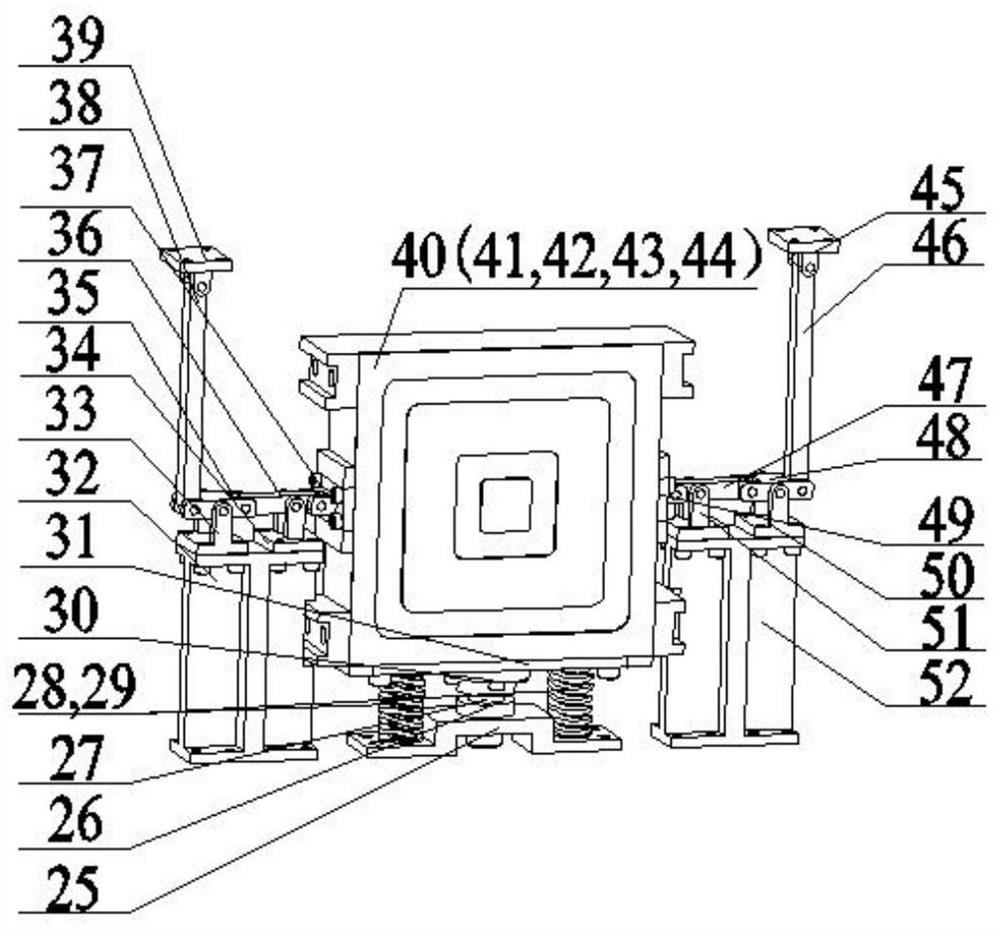

[0052] according to Figure 1 to Figure 21 As shown, the present invention provides a magnetic levitation type quasi-zero stiffness electromagnetic vibration isolator with active negative stiffness, such as figure 1 As shown, the magnetic levitation type quasi-zero stiffness electromagnetic isolator that can realize active and passive negative stiffness in the present invention includes an actuator part and an electric control part. The actuator part consists of base 1, mover assembly 2, stator assembly 3 (including left electromagnet assembly 4, middle electromagnet assembly 5, right electromagnet assembly 6, front connecting plate 7, rear connecting plate 8), spring assembly 9 and The supporting plate 10 is formed, and the movable subassembly 2 and the stator assembly 3 together form an electromagnetic negative stiffness mechanism; the electric control part is composed of a displacement sensor 132, a controller 133, a driver 134, and a DC stabilized power supply 135. The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com