A Negative Pressure-Based EFI Fuel Pump Detection System

A detection system and fuel pump technology, applied in the direction of charging system, engine test, machine/structural component test, etc., can solve problems such as danger and traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

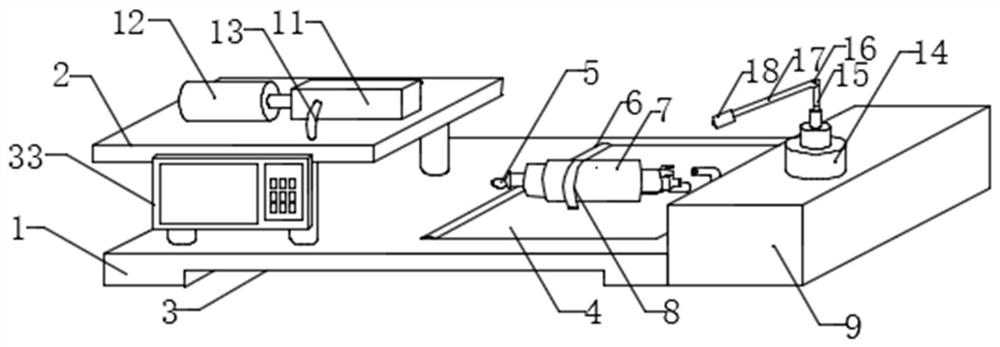

[0028] Such as Figure 1-6 As shown, a negative pressure-based EFI fuel pump detection system includes a mounting plate (1), four supporting columns (10) are installed on the top of one side of the mounting plate (1), and each supporting column (10) The top is connected with a support plate (2), the middle part of the bottom of the installation plate (1) is provided with a slot (3), the front of the support plate (2) is equipped with a control panel (33), and one of the top of the support plate (2) A negative pressure pump (11) is installed on the side, and both sides of the negative pressure pump (11) are connected with a suction pipe (13). ) and the negative pressure pump (11) are connected internally.

[0029] A runner (6) is installed in the middle of the installation plate (1), and the other end of the runner (6) is connected to a rotating plate (4). The surface of the rotating plate (4) is provided with a strap (8). (7) is installed inside the strap (8), the other side...

Embodiment 2

[0037] Such as Figure 1-6 As shown, a negative pressure-based EFI fuel pump detection system includes a mounting plate (1), four supporting columns (10) are installed on the top of one side of the mounting plate (1), and each supporting column (10) The top is connected with a support plate (2), the middle part of the bottom of the installation plate (1) is provided with a slot (3), the front of the support plate (2) is equipped with a control panel (33), and one of the top of the support plate (2) A negative pressure pump (11) is installed on the side, and both sides of the negative pressure pump (11) are connected with a suction pipe (13). ) and the negative pressure pump (11) are connected internally.

[0038] The other side of the top of the mounting plate (1) is equipped with a rotating rod (20), and one end of the rotating rod (20) is provided with a delivery port (21), and one side of the mounting plate (1) is equipped with a fuel tank (9), and the fuel tank ( 9) An o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com