Pentane spraying type polyurethane combined polyether and preparation method thereof

A technology combining polyether and polyurethane, which is applied in the field of rigid polyurethane foam, can solve problems such as the decrease of expansion ratio and foam physical properties, poor dimensional stability of foaming agent, and great influence on foam flame retardant effect, and achieve overall density and comprehensive Low cost, improved dimensional stability of the system, and the effect of solving the problem of blowing agent replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

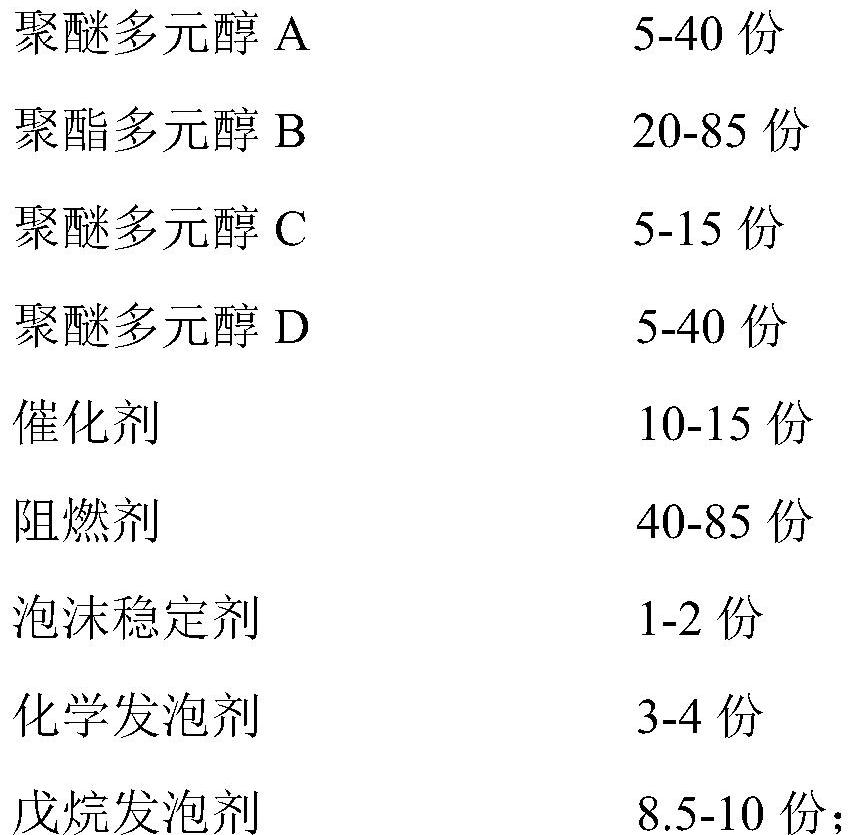

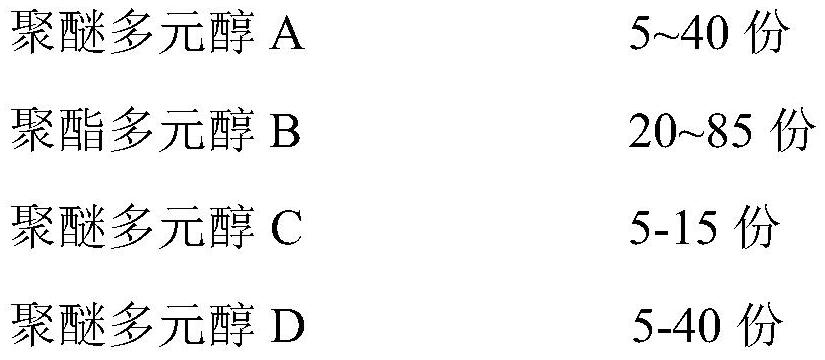

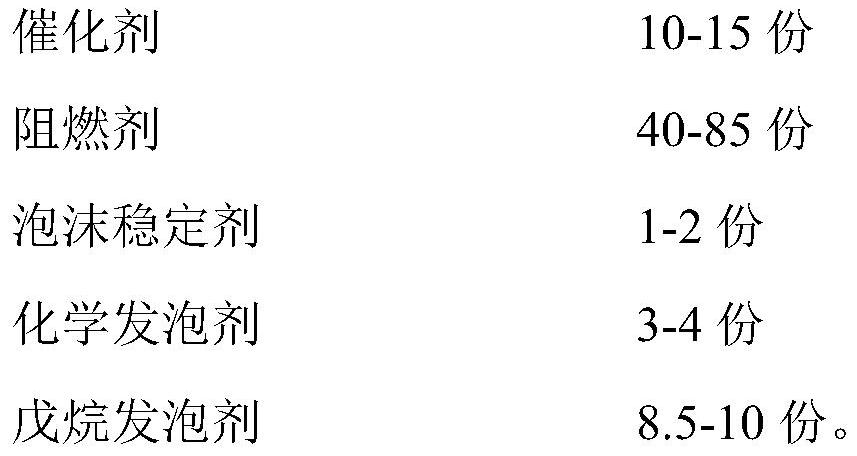

Method used

Image

Examples

Embodiment 1

[0028] Weigh polyether polyol R5118G: 35 parts; polyester polyol PS2352: 45 parts; polyether polyol R403: 10 parts; polyether polyol C310: 10 parts; silicone oil L6688: 2 parts; water: 3.4 parts; A1: 4 parts; PC5: 2 parts; A33: 2.7 parts; PC41: 1.2 parts; TMR-2: 0.4 parts; CA50: 1.2 parts; TCPP: 40 parts; TEP: 20 parts; Isopentane: 9.5 parts.

[0029] Put the weighed raw materials into the reaction kettle in turn, stir at room temperature for 0.5 hours, take them out for inspection, meet the process parameters, and produce foam, that is, the pentane spray type polyurethane combined polyether, take it out from the reaction kettle and put it into a barrel for storage , as component A, component A is clear and transparent.

[0030] Component A and component B (polymethylene polyphenyl isocyanate) are mixed according to the weight ratio of A:B=100:110 and sprayed to make pentane spray polyurethane foam, and the product quality index is tested.

Embodiment 2

[0032] Weigh polyether polyol R8345: 40 parts; polyester polyol PS2412: 20 parts, polyether polyol R403: 5 parts; polyether polyol C310: 35 parts; silicone oil S1087: 2 parts; water: 3.3 parts; A1: 2 parts; PC5: 2 parts; A33: 3 parts; PC41: 2 parts; TMR-2: 0.4 parts; CA50: 2.1 parts; TCPP: 60 parts; TEP: 15 parts;

[0033] Put the weighed raw materials into the reaction kettle in turn, stir at room temperature for 0.5 hours, take them out for inspection, meet the process parameters, and produce foam, that is, the pentane spray type polyurethane combined polyether, take it out from the reaction kettle and put it into a barrel for storage , as component A, component A is clear and transparent.

[0034] Component A and component B (polymethylene polyphenylisocyanate) are mixed according to the weight ratio of A:B=100:130 and sprayed to make pentane spray polyurethane foam, and the product quality index is tested.

Embodiment 3

[0036] Weigh polyether polyol R8345: 5 parts; polyester polyol B175: 85 parts, polyether polyol R403: 5 parts; polyether polyol C310: 5 parts; silicone oil S1087: 2 parts; water: 3.6 parts; A1: 2 parts; PC5: 2 parts; A33: 3 parts; PC41: 2 parts; TMR-2: 0.9 parts; CA50: 2.1 parts; TCPP: 60 parts; TEP: 20 parts; Isopentane: 9 parts.

[0037] Put the weighed raw materials into the reaction kettle one by one, stir at room temperature for 0.5 hours, take them out for inspection, meet the process parameters, and produce foam, that is, the pentane spray type polyurethane combined polyether, take it out from the reaction kettle and put it into a barrel for storage , as component A, component A is clear and transparent.

[0038] Component A and component B (polymethylene polyphenylisocyanate) are mixed according to the weight ratio of A:B=100:130 and sprayed to make pentane spray polyurethane foam, and the product quality index is tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com