Blue-gray three-silver low-emissivity coated glass and preparation method thereof

A low-emissivity coating, gray technology, applied in the field of magnetron sputtering coating, can solve the problems of insufficient color, heavy color tone on the film surface, not many types, etc., and achieve the effect of enriching the color system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

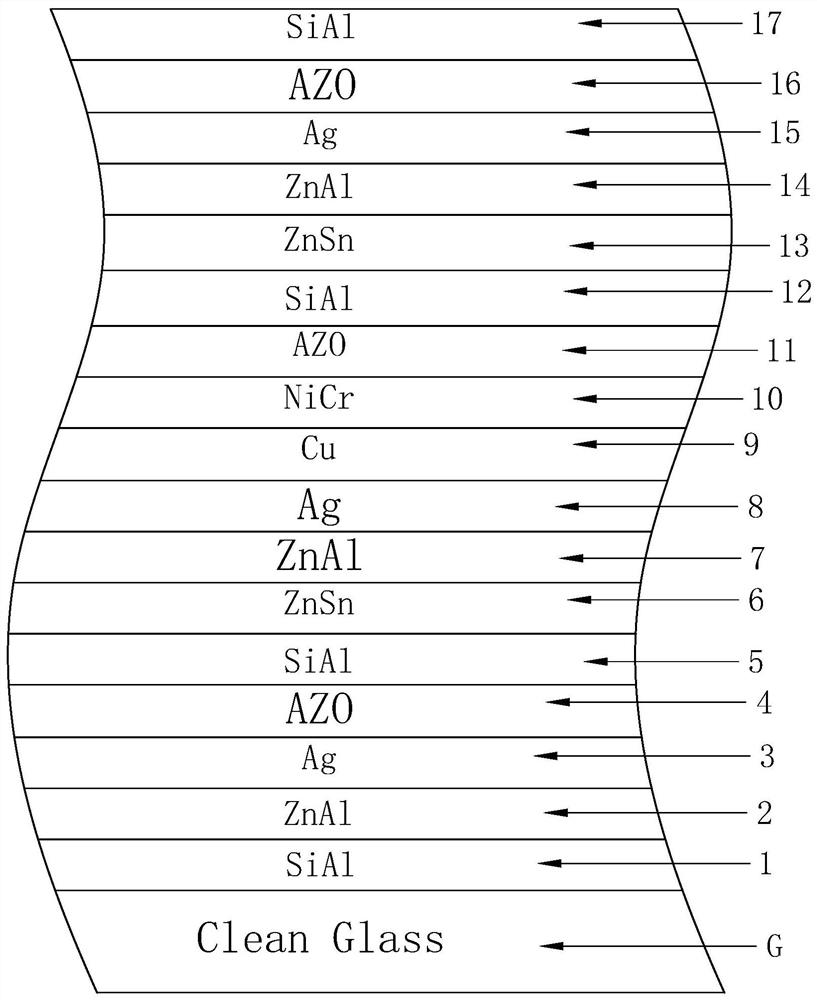

[0056] Such as figure 1 As shown, a blue-gray triple-silver low-emissivity coated glass includes a glass substrate layer G and a coating layer, and the coating layer is sequentially compounded with seventeen film layers outward from the glass substrate layer G, wherein the first Layer 1 and the second layer 2 are the first dielectric combination layer, the third layer 3 is the low-radiation function layer, the fourth layer 4 is the first barrier protection layer, the fifth layer 5 is the crystal bed dielectric layer, the sixth layer 6 and the The seventh layer 7 is the second dielectric composite layer, the eighth layer 8 is the low-radiation functional layer, the ninth layer 9 is the low-radiation functional layer, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com