Wavelength conversion member and method for manufacturing the same

A technology of wavelength conversion and wavelength conversion materials, which is applied in the field of wavelength conversion components and its manufacturing, can solve problems such as color deviation and deterioration, and achieve the effect of reducing color deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

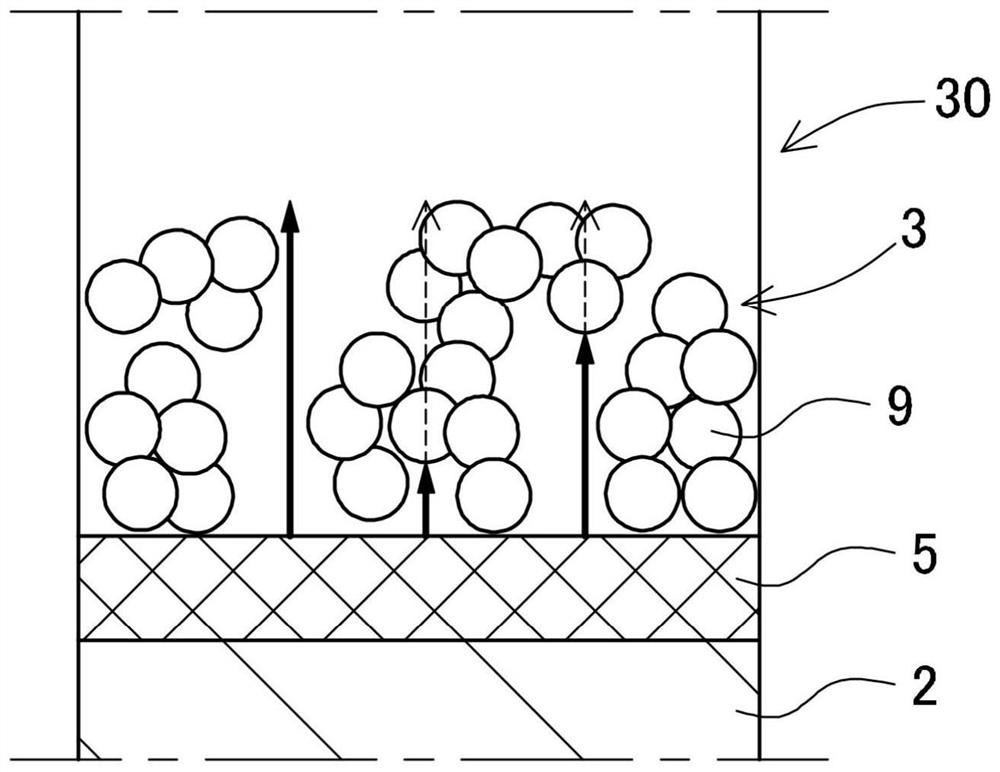

[0116] Next, an embodiment of a wavelength converting member was fabricated. Here, the wavelength conversion member of the example was fabricated at a given compounding ratio. Specifically, the resin 10, the phosphor 9, the filler 20 (silica), and the filler (alumina) different from the filler 20 are mixed, and the phosphor paste obtained is screen printed on the translucent member 4. The entire surface, that is, one main surface is coated with phosphor layer 3 . Regarding Examples 1 to 3, phosphor 9 used Y 3 (Al,Ga) 5 o 12 : Phosphor 1 and Phosphor 2 represented by Ce (It should be noted that the emission peak wavelength of Phosphor 1 is around 540nm, and the emission peak wavelength of Phosphor 2 is around 535nm.), (Sr, Ca)AlSiN 3 : Phosphor 3 represented by Eu These three phosphors. Regarding the compounding ratio of the phosphors in Examples 1 to 3, the phosphor 1 was 21.75% by mass, the phosphor 2 was 65.25% by mass, and the phosphor 3 was 13% by mass. As resin 10, ...

Embodiment 4~5

[0123] On the other hand, as Example 4, except that the compounding ratio of the phosphor is 22.08% by mass for the phosphor 1, 66.23% by mass for the phosphor 2, and 11.7% by mass for the phosphor 3, it is the same as that of Examples 1 to 3. 3. A wavelength conversion member was produced in the same manner. In Example 4, regarding the content of the phosphor in the phosphor layer 3, the resin is set to 100 parts by mass, and the content obtained by adding the contents of the above three kinds of phosphors is 250 parts by mass. Silicon oxide is 70 parts by mass, filler (alumina) different from filler 20 is 5.3 parts by mass, and the mixing volume ratio of phosphor and filler 20 to resin, (silica+phosphor) / resin is 0.93, also in Within the range of 0.5 or more and 1.0 or less. The standard deviation (mean value) of the hue x was 0.0033, which was almost equivalent to Example 3.

[0124] In addition, as Example 5, the compounding ratio of the phosphor was the same as in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com