Modified graphite material, preparation method and application thereof and lithium ion battery

A graphite material and modification technology, applied in graphite, secondary batteries, battery electrodes, etc., can solve problems such as low capacity, poor impedance performance, and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

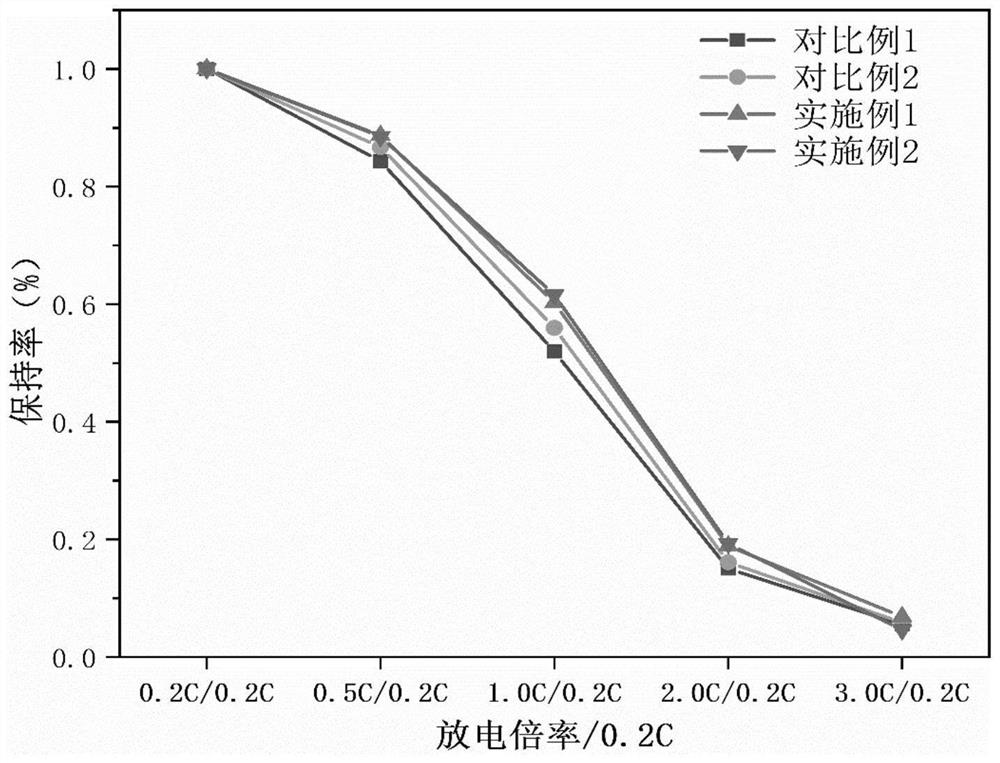

Examples

Embodiment 1

[0051]A method of preparing a modified graphite material comprising the steps of:

[0052]S1, preparation graphite particles: pulverizing petroleum coke to D50 is 10 μm, placed in a horizontal coating, under high purity nitrogen gas protection, heat treatment at 630 ° C for 8 h; then transfer material to an Aixson graphizer, At 3000 ° C for 30 h, graphite particles;

[0053]S2, once: Place the graphite particles and oily graphene pulp (mass ratio of 100: 9) in the fusion machine, the fusion machine rotation is 280 r / min, the fusion time is 20 min;

[0054]The material was transferred to a carbonization furnace under an inert atmosphere, and the first carbonization process was 22 hours at 1150 ° C for 22 hours to obtain graphite particles.

[0055]S3, twice cover:

[0056]Add polyvinylpyrrolidone (PVP) and deionized water (7:10) in 5000 ml of three flasks (7:10), heating to 80 ° C to 90 ° C, stirring the rotation speed of 60 r / min, stirring time is 2 h, ensuring two components Uniform dispersio...

Embodiment 2

[0060]In addition to step S3, PVP: Dermage water = 5: 10, the remaining steps and conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com