Cam-driven clamping feeder

A technology of clamping feeding and cams, which is applied in thin material processing, winding strips, transportation and packaging, etc. It can solve the problems of low synchronization of actions, wear of copper strip surface, unstable structure, etc., and achieve space utilization. Sufficient, reduced installation requirements, reduced contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

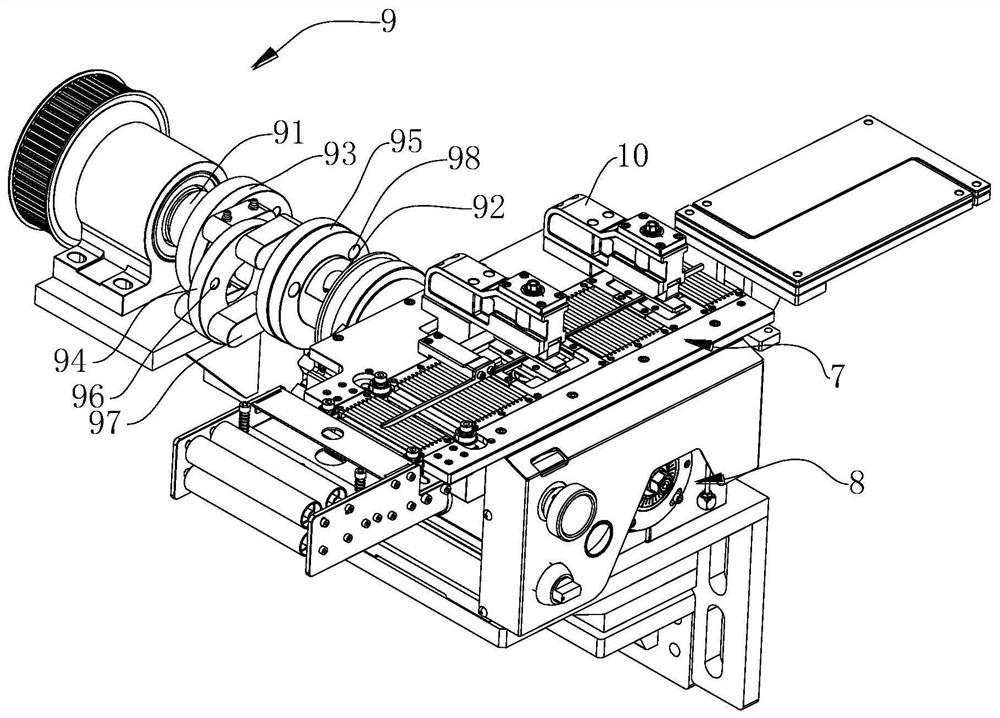

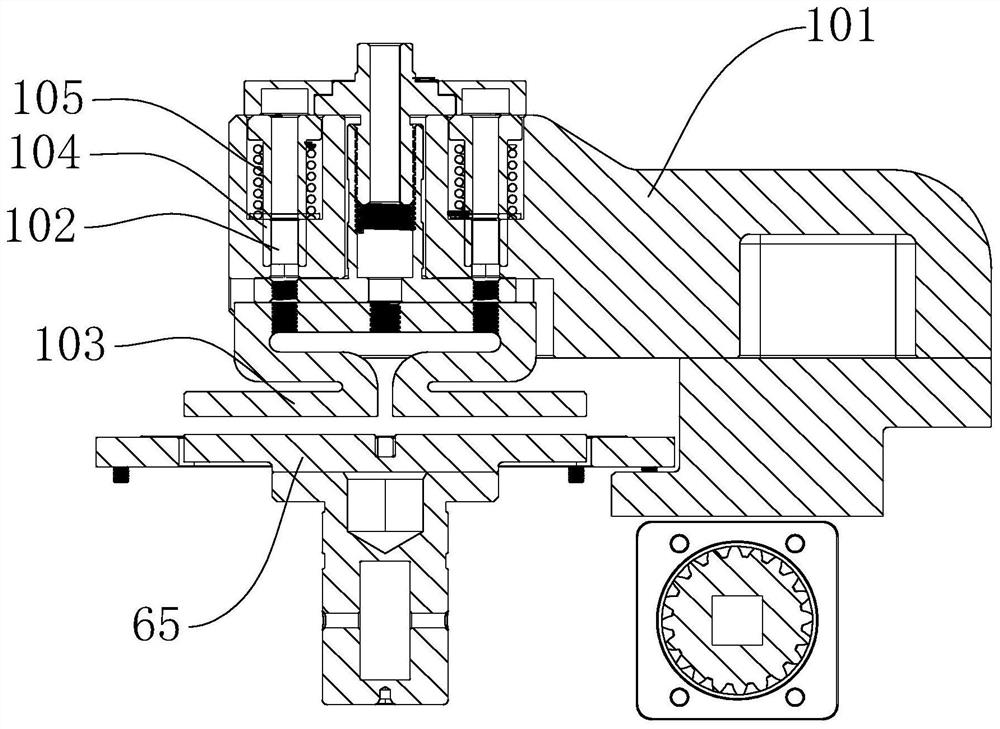

[0036] A cam-driven clamping feeder, refer to figure 1 As shown, it includes a feeding needle roller platform 7 , a feeding host 8 , an eccentric transmission mechanism 9 , and a floating manipulator 10 . The feeding needle roller platform 7 is assembled and carried on the top of the feeding host 8 . refer to figure 2 , the structure of the feeding needle roller platform 7 is mainly assembled by the needle roller seat 71 and the needle roller shaft 72, and the needle roller shaft 72 is assembled on the needle roller seat 71 so that the needle roller shaft 72 is higher than the surface of the working platform to realize the rolling of the needle roller shaft 72 Transfer artifacts. It needs to be explained here that the product of this design is used for conveying belt-shaped workpieces, such as copper strips, metal sheets or metal strips. Due to the rolling friction method, the friction force is small and the impact on the surface of the workpiece is less.

[0037] The wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com