Material friction abnormal sound test bed with magnetic suspension type objective table

A stage and magnetic levitation technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problem that the stage cannot guarantee the mute effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

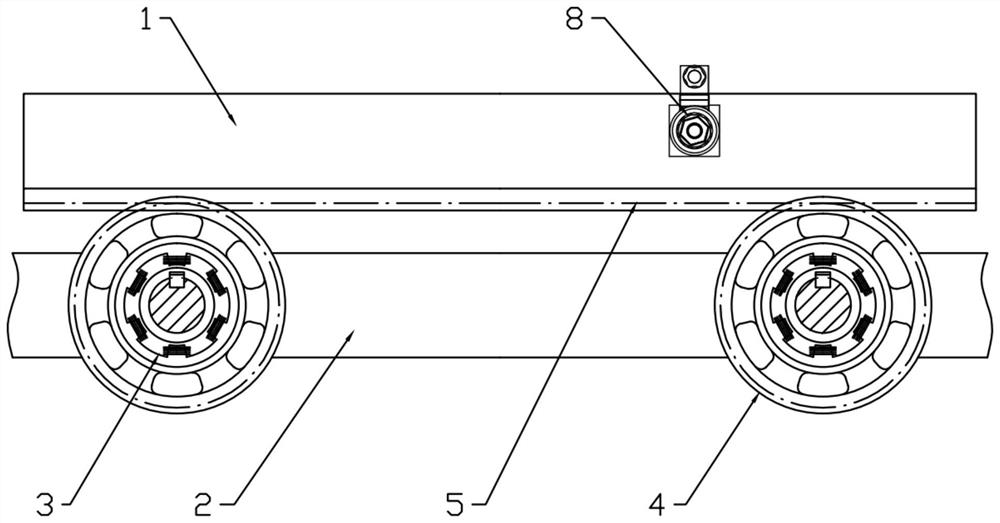

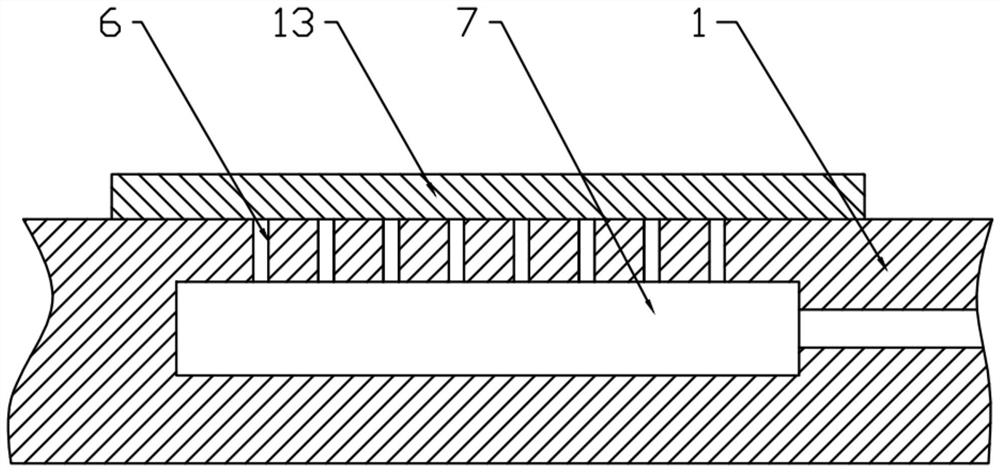

[0022] This embodiment is basically as figure 1 , figure 2 Shown: a material friction noise test bench with a magnetic levitation stage 1, including a stage 1, a stand 2 and four magnetic bearings 3, the magnetic bearing 3 is an active magnetic bearing 3, and the stage 1 is placed on the table Above the frame 2, the magnetic bearing 3 is arranged in parallel, the rotor of the magnetic bearing 3 is pierced with a mounting shaft, the rotor and the mounting shaft are connected by a key, two magnetic bearings 3 are mounted on one mounting shaft, and the two ends of the mounting shaft are fixed on the stand 2, a gear 4 is coaxially fixedly connected to the outer ring of the magnetic bearing 3, the gear 4 is a cylindrical helical gear 4, and two racks 5 are fixedly connected to the bottom surface of the stage 1, and each rack 5 is respectively connected to two Gear 4 meshes.

[0023] The central area of the top surface of the stage 1 is provided with a placement area, and the i...

Embodiment 2

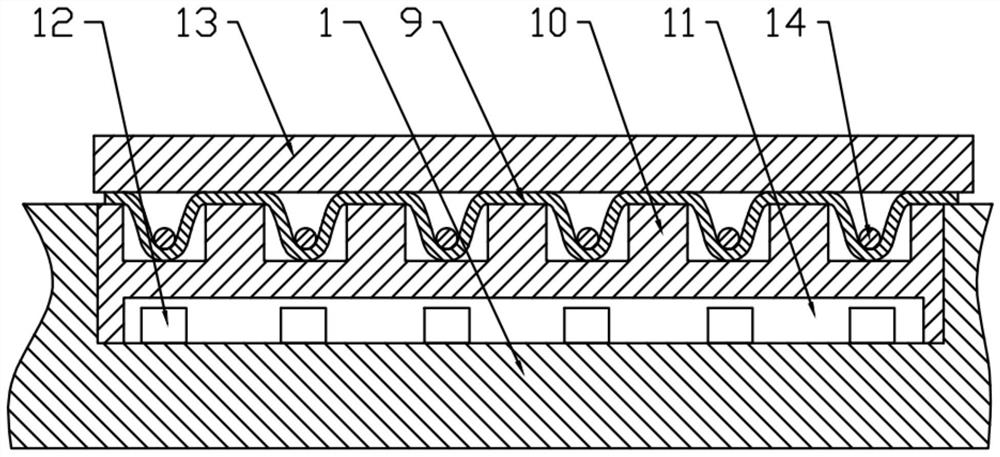

[0028] This embodiment is basically as image 3 As shown, the difference from Embodiment 1 is that: a latex layer 9 made of natural latex is adhered on the top surface of the stage 1 , and nickel-iron alloy particles 14 are embedded inside the latex layer 9 . A nylon backing plate 10 is placed under the latex layer 9, the backing plate 10 is embedded in the object stage 1 and the upper end surface is flush, a cavity 11 is provided in the backing plate 10, and grooves are provided on the cavity 11 corresponding to the positions of the particles 14 , the groove is larger than the particle 14, and an electromagnet 12 is also arranged in the cavity 11.

[0029] After the electromagnet 12 is energized, the particles 14 can be sucked into the groove. Because latex has good elastic deformation capacity, the latex layer 9 is depressed. The effect of the depression is to attach the latex layer 9 to the surface of the test sample 13. Finally, a certain degree of vacuum is generated, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com