Chemical flooding multi-medium central channel type injection allocation device

A central channel, multi-media technology, applied in drill pipe, casing, wellbore/well components, etc., can solve the problems of inability to perform injection profile testing, production under pressure, and small number of injection layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

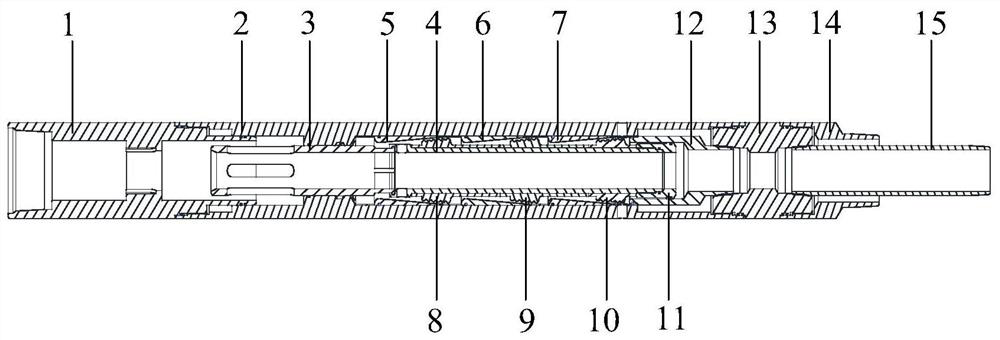

[0028] The chemical flooding multi-media central channel type dispenser of the present invention includes an upper joint 1, an outer sleeve 2, an adjustment sleeve 3, a throttling inner sleeve 4, a bellows locking joint 11, a lower joint inserting a sealing nipple 12, Lower joint main body 13, throttling outer sleeve and throttling bellows;

[0029] One end of the upper joint 1 is connected to the oil pipe, and the other end is connected to one end of the outer sleeve 2; the other end of the outer sleeve 2 is connected to the external thread of one end of the lower joint main body 13, and the inner thread of one end of the lower joint main body 13 is inserted and sealed with the lower joint. One end of the short joint 12 is threaded; the other end of the lower joint cylinder 13 is externally threaded to one end of the lower joint variable buckle 14, and the other end of the lower joint main body 13 is internally threaded to one end of the lower joint double male short joint 15;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com