Steel support and steel trestle integrated structure and construction method thereof

A construction method and technology of steel trestle bridges, which are applied in the direction of foundation structure engineering, excavation, bridges, etc., can solve problems such as difficult construction, large number of upright piles, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

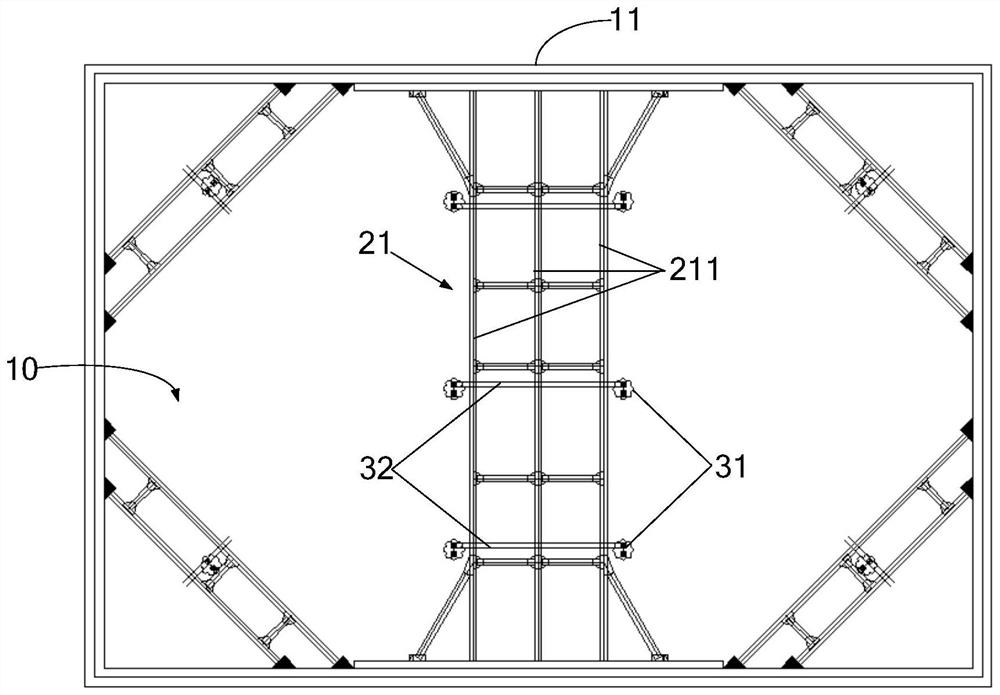

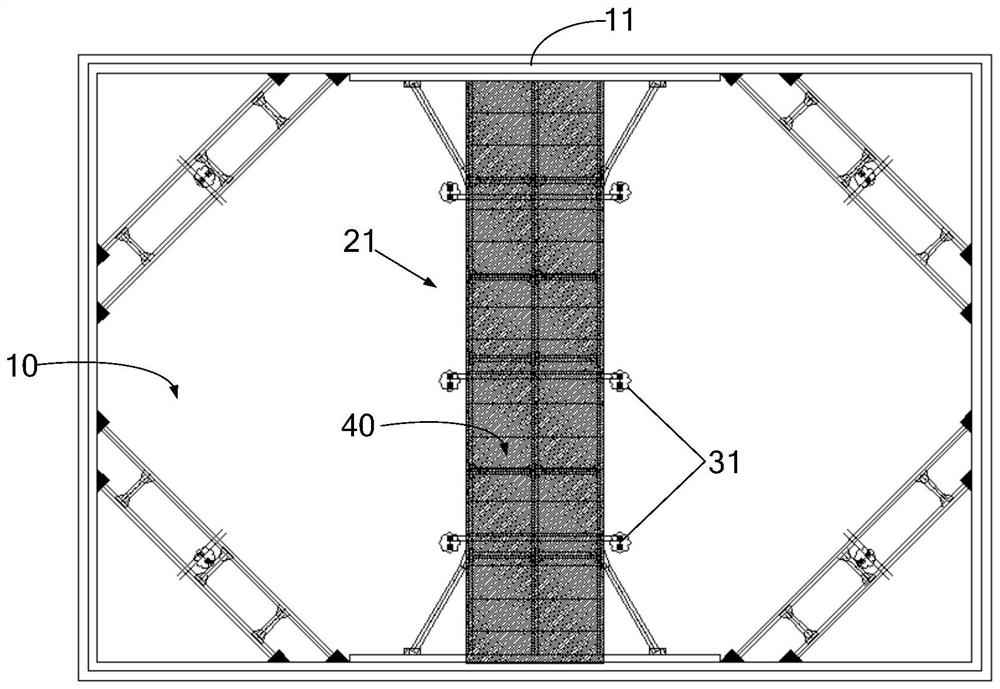

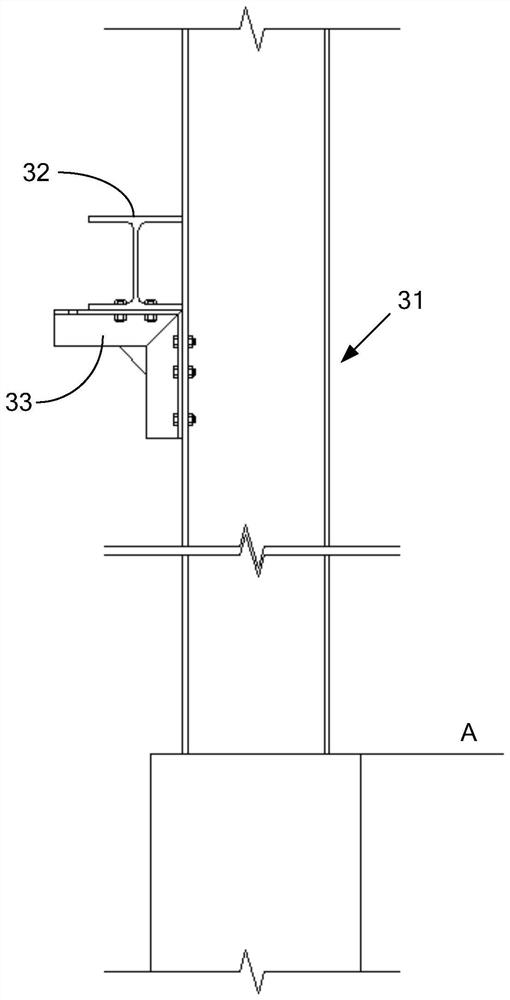

[0052]When the plurality of column piles 31 are applied in the foundation pit 10 in the foundation pit 10, the plurality of the column pile 31 is arranged in the longitudinal direction of the steel to the support 21, and the mounting support between the column pile 31 Beam 32.

[0053]When the steel penetration 21 is taken over the base pit 10 in the foundation pit 10, the plurality of H-type pair beam 211 is placed on the beam 32, and the two ends of the multi-type H-shaped support beam 211 are each. Connect to the foundation pit.

[0054]When the top surface of the steel counter 21 is laid in step 3, the gasket 50 is laid in the top surface of the plurality of H-type pair beam 211.

[0055]Specifically, the bull leg 33 is applied to each pair of the same side and the same height of the column pile 31, and then the trace 32 is mounted between each pair of column piles 31, and the two ends of the beam 32 are The portion is fixed to the respective bull leg 33, the size of the bull leg 33 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com