Cloth pressing device of sewing machine and working method of cloth pressing device

The technology of a cloth pressing device and sewing machine is applied in the directions of sewing machine components, cloth pressing mechanism, sewing equipment, etc., which can solve the problems of work fatigue, affect the processing efficiency, increase the workload of workers, etc., and achieve the effect of increasing the tension force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

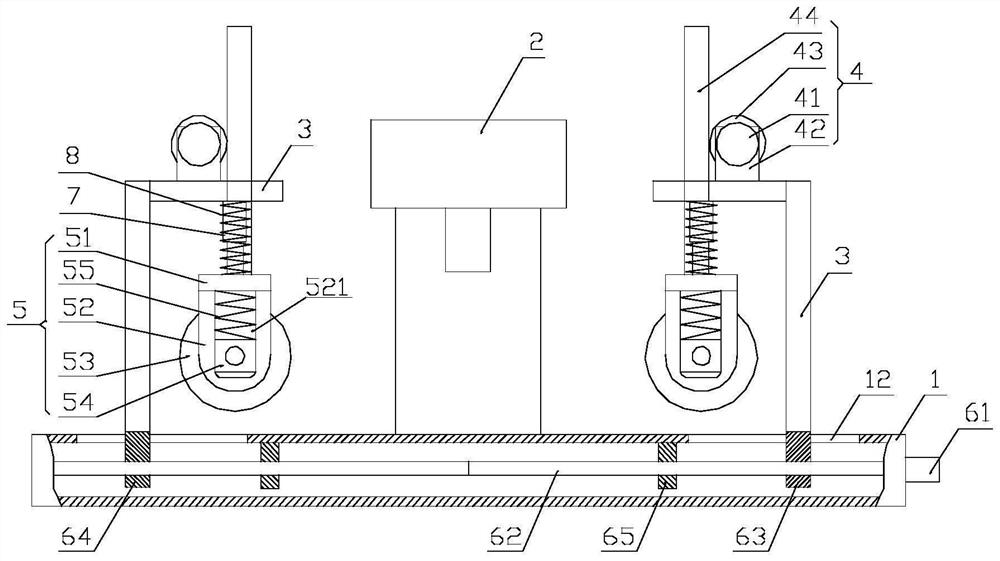

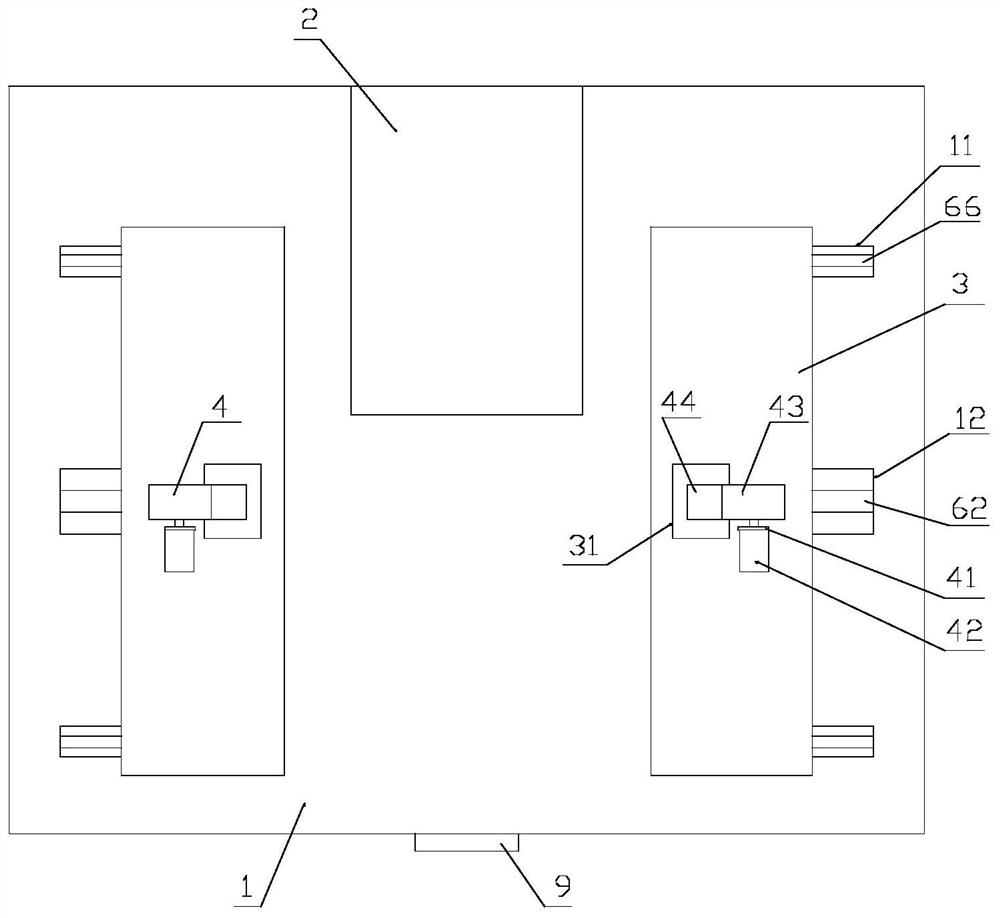

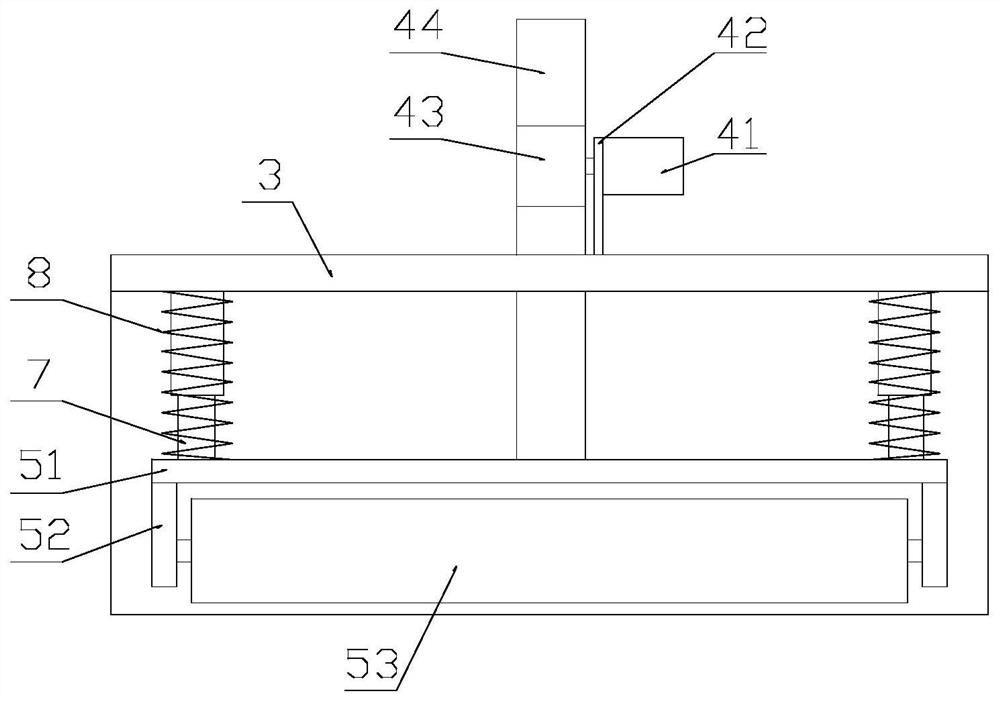

[0036] if Figure 1-4 As shown, a cloth pressing device of a sewing machine includes a workbench 1, a sewing machine body 2, a tensioning seat 3, a lifting mechanism 4, a pressing wheel mechanism 5, a tensioning mechanism 6 and a control switch group 9, and the sewing machine body 2 is fixed Above the workbench 1, the tension seat 3 is symmetrically arranged on both sides of the workbench 1 with the sewing machine body 2 as the center, the tension seat 3 is slidingly connected with the workbench 1, and the longitudinal center position of the tension seat 3 is A lifting mechanism 4 is provided, and a pressure roller mechanism 5 is connected to the bottom of the lifting mechanism 4, and the pressure roller mechanism 5 includes a connecting horizontal plate 51, an end plate 52, a pressure roller 53, a first slider 54 and a first spring 55 , the two ends of the pressure wheel 53 are provided with end plates 52, the end plates 52 are provided with a first slider 54, and the ends of...

Embodiment 2

[0039] if Figure 1-4 As shown, a cloth pressing device of a sewing machine includes a workbench 1, a sewing machine body 2, a tensioning seat 3, a lifting mechanism 4, a pressing wheel mechanism 5, a tensioning mechanism 6 and a control switch group 9, and the sewing machine body 2 is fixed Above the workbench 1, the tension seat 3 is symmetrically arranged on both sides of the workbench 1 with the sewing machine body 2 as the center, the tension seat 3 is slidingly connected with the workbench 1, and the longitudinal center position of the tension seat 3 is A lifting mechanism 4 is provided, and a pressure roller mechanism 5 is connected to the bottom of the lifting mechanism 4, and the pressure roller mechanism 5 includes a connecting horizontal plate 51, an end plate 52, a pressure roller 53, a first slider 54 and a first spring 55 , the two ends of the pressure wheel 53 are provided with end plates 52, the end plates 52 are provided with a first slider 54, and the ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com