Preparation method and application of ruthenium-doped cobalt phosphide electrocatalyst

A catalyst, cobalt-electric technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problem of high overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

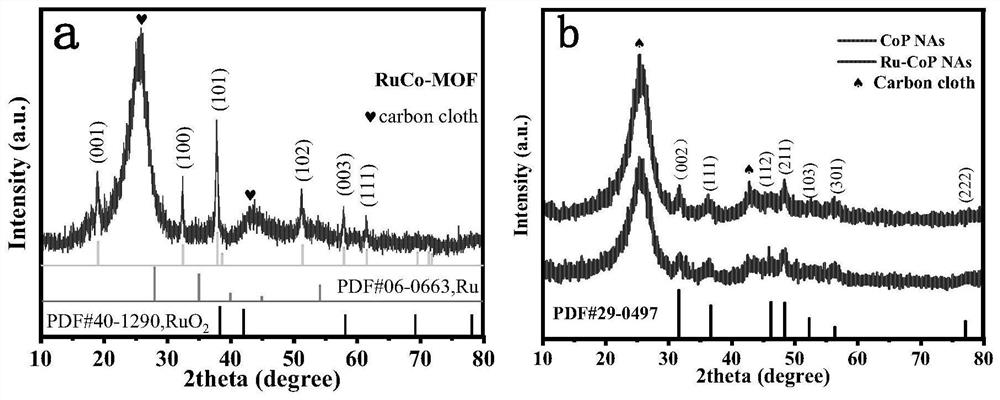

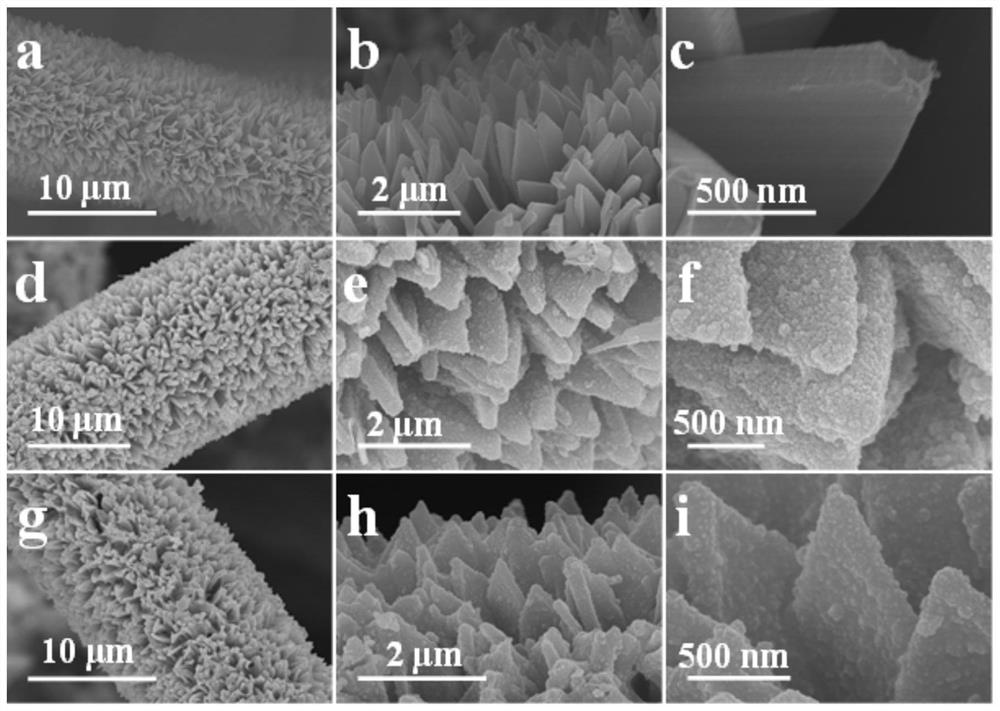

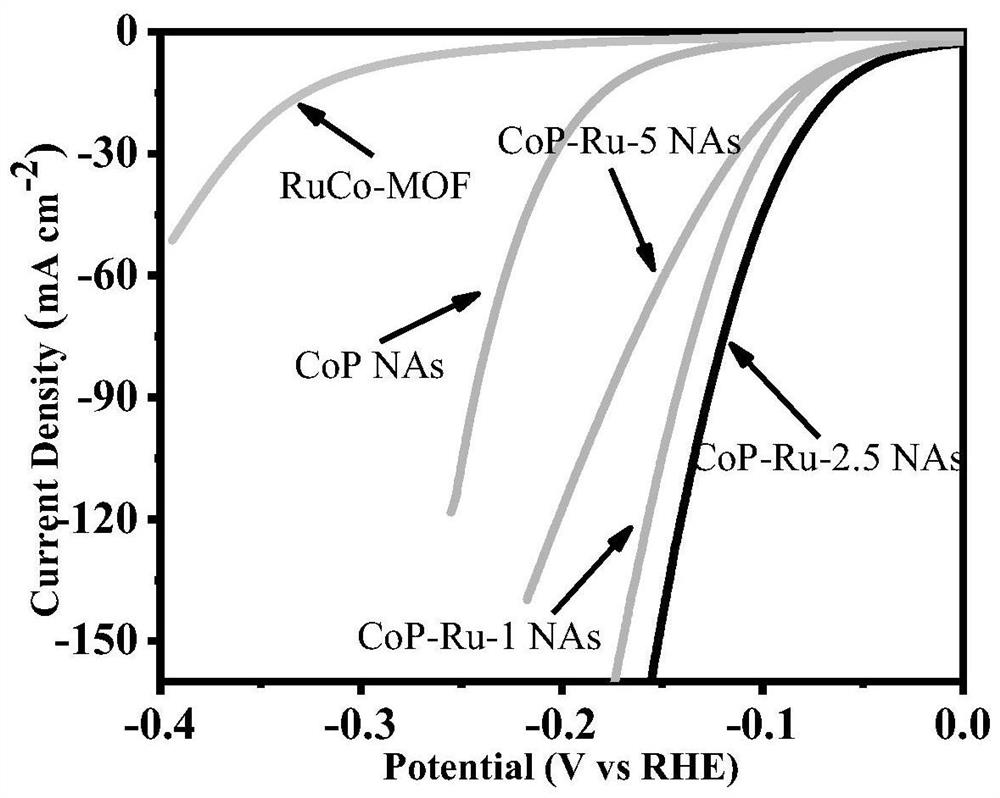

[0041] Preparation of Ru-doped CoP electrocatalysts (Ru-CoP-1NAs) based on carbon cloth (CC):

[0042] The commercial carbon cloth was refluxed with nitric acid for 10 h at 120 °C, followed by ultrasonic cleaning with acetone, ethanol and deionized water.

[0043] Weigh 0.5821g Co(NO 3 ) 2 ·6H 2 O was dissolved in 40mL deionized water, and after stirring evenly, solution A was obtained; 1.3136g 2-methylimidazole (C 4 h 6 N 2 ) was dissolved in 40mL deionized water, and stirred evenly to obtain solution B; then solution B was poured into solution A, and stirred evenly to form a blue solution; the cleaned carbon cloth (2cm×5cm) was immersed in the blue precursor After the reaction, the carbon cloth turned blue, and then the carbon cloth was taken out, washed with water and alcohol, and dried at 60°C for 12 hours to obtain Co-MOF.

[0044] Weigh 1.2g NaOH and dissolve in 49mL deionized water, add 1mL RuCl 3 (5mg mL -1 ) solution was stirred evenly, and the Co-MOF was imme...

Embodiment 2

[0047] Preparation of Ru-doped CoP electrocatalysts (Ru-CoP-2.5NAs) based on carbon cloth (CC):

[0048] The preparation method of this electrocatalytic material is basically the same as that of Example 1, the difference is that: RuCl 3 The volume of the solution was 2.5 mL, and the volume of deionized water was 47.5 mL.

Embodiment 3

[0050] Preparation of Ru-doped CoP electrocatalysts (Ru-CoP-5NAs) based on carbon cloth (CC):

[0051] The preparation method of this electrocatalytic material is basically the same as that of Example 1, the difference is that: RuCl 3 The volume of the solution was 5 mL, and the volume of deionized water was 45 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com