A method for COFs thin films to achieve high-efficiency gas separation through post-synthetic modification

A technology for separating gases and thin films, which is applied in separation methods, semipermeable membrane separation, and dispersed particle separation, etc., to achieve the effects of easy processability, low raw material cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

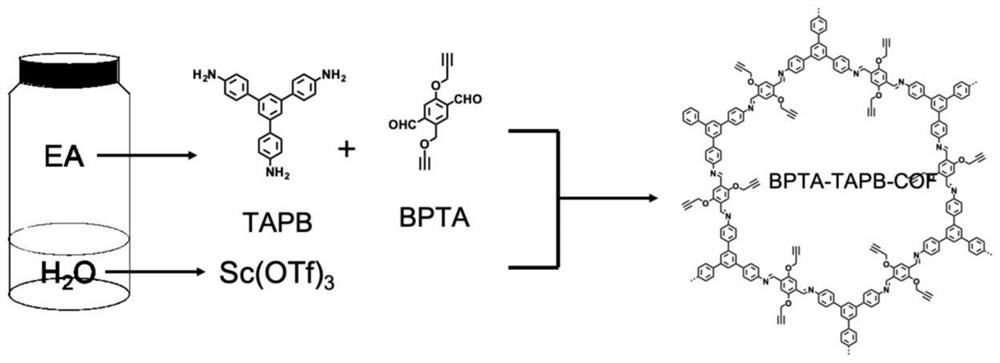

[0059] (1) Add TAPB and BPTA into a beaker filled with ethyl acetate, mix well to obtain solution A, wherein the concentration ratio of TAPB and BPTA is 2:3; Sc(OTf) 3 Add deionized water to the beaker and mix well to obtain Solution B. Among them, the concentration of aminoaromatic compounds in solvent II is 1-4 μM / mL, the concentration of aromatic aldehyde-based compounds in solvent II is 1.5-6 μM / mL, and the concentration of scandium trifluoromethanesulfonate in solvent I 0.5~2μM / mL.

[0060] (2) Slowly add solution B into a 50mL glass bottle, and then use a funnel to add solution A to solution B at a constant speed. After standing for 10 seconds, the solution will automatically separate into layers, seal the reaction system, and stand at 10°C for 15 days. TAPB-BPTA-COFs film material was generated in situ on the glass bottle wall. The reaction system and reaction process for preparing TAPB-BPTA-COFs film are as follows: figure 1 shown;

[0061] (3) Pour off the reactio...

Embodiment 2

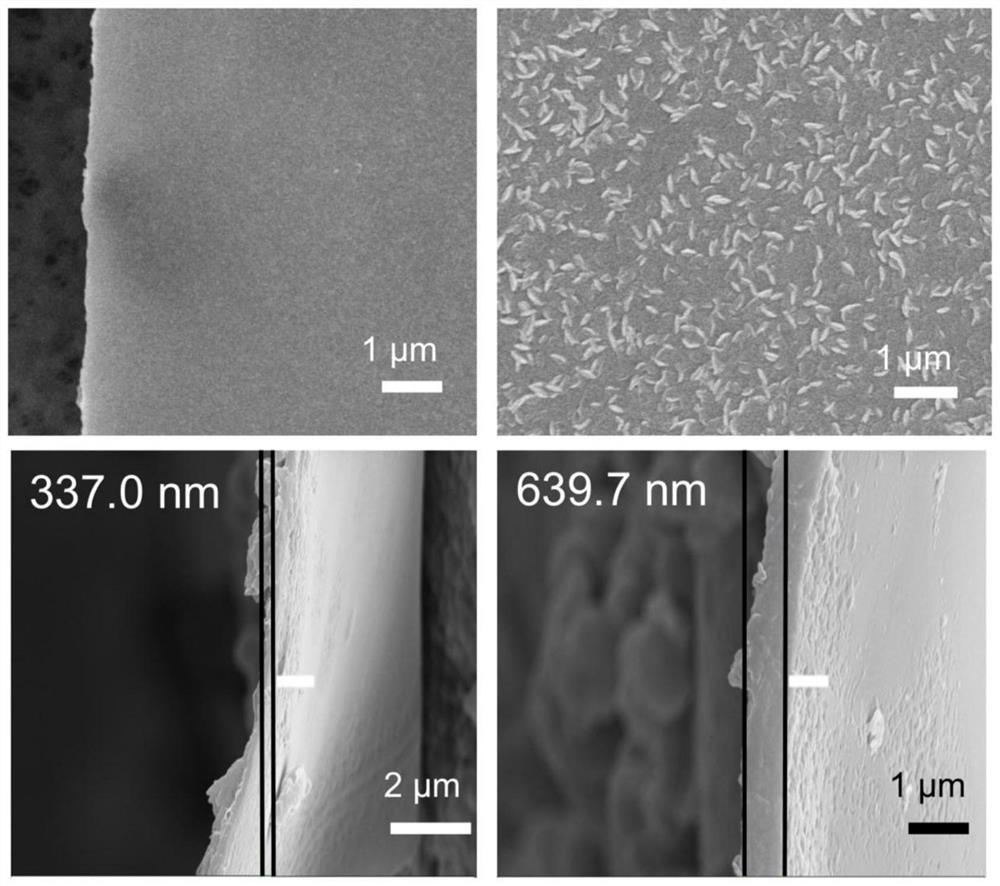

[0076] (1) Using a 50mL glass bottle as a reaction vessel, dissolve p-azidobenzoic acid (N 3 -Ph-COOH), ascorbic acid (AA) and anhydrous CuSO 4 .

[0077](2) Place the TAPB-BPTA-COFs@PVDF membrane obtained above in a 3 -Ph-COOH solution system soaked for 2 to 4 hours, and then dissolved in ascorbic acid (AA) and anhydrous CuSO 4 The solution is fully mixed and added to the solution system of the azide compound, and the reaction temperature is controlled by a constant temperature oscillator, and the reaction time is 12 hours. This post-synthetic modification strategy is as Figure 7 shown.

[0078] (3) After the reaction, the COFs film was clamped out from the solution, soaked and washed with tetrahydrofuran for 3 to 5 times, and then dried under vacuum at 60°C for more than 12 hours to obtain COFs@PVDF-N 3 -Ph-COOH.

[0079] (4) Soak the dried membrane in 0.027mM / mL anhydrous Cu(CH 3 COO) 2 in methanol solution for 24 hours, and then dried under vacuum at 60°C for more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com