Method for realizing efficient gas separation of COFs film through modification after synthesis

A technology for separating gases and membranes, used in separation methods, semi-permeable membrane separation, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

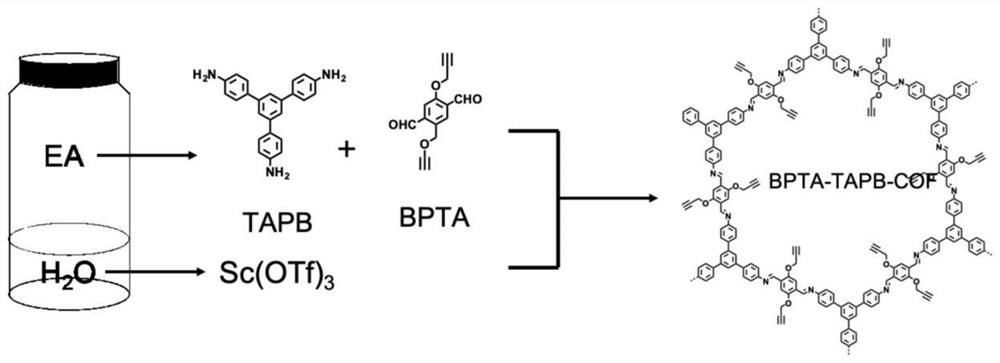

[0059] (1) Add TAPB and BPTA into a beaker filled with ethyl acetate, mix well to obtain solution A, wherein the concentration ratio of TAPB and BPTA is 2:3; Sc(OTf) 3 Add deionized water to the beaker and mix well to obtain Solution B. Among them, the concentration of aminoaromatic compounds in solvent II is 1-4 μM / mL, the concentration of aromatic aldehyde-based compounds in solvent II is 1.5-6 μM / mL, and the concentration of scandium trifluoromethanesulfonate in solvent I 0.5~2μM / mL.

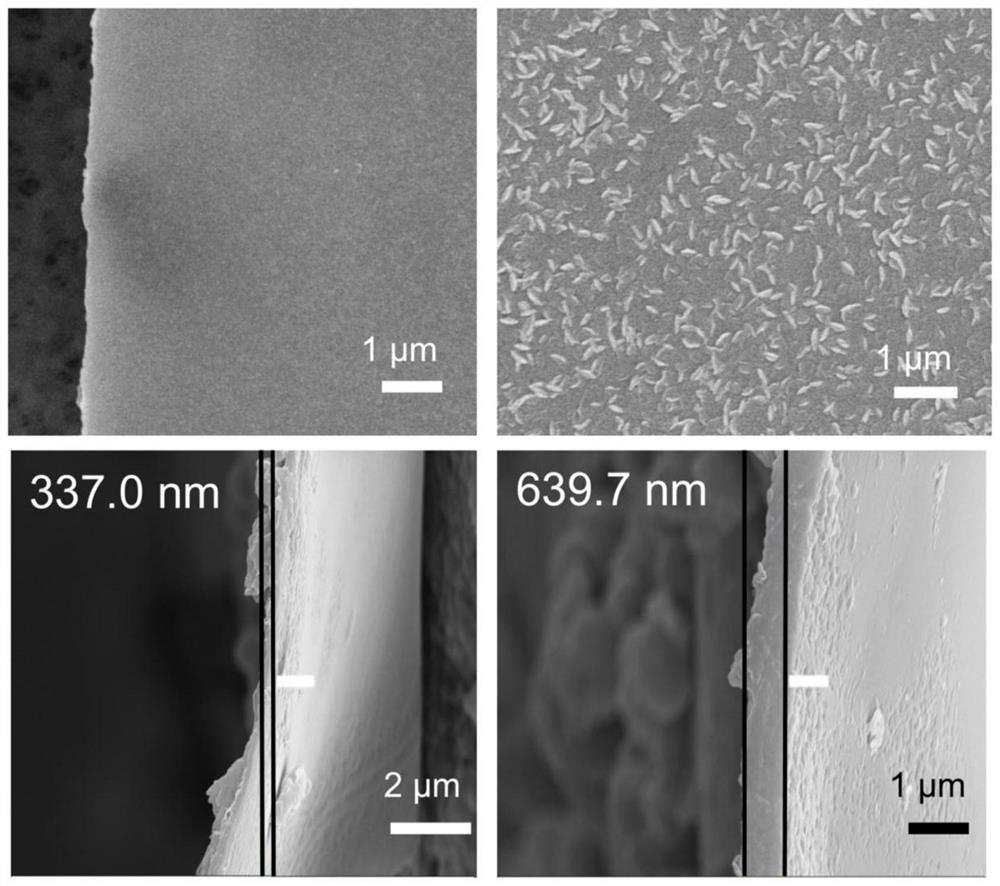

[0060] (2) Slowly add solution B into a 50mL glass bottle, and then use a funnel to add solution A to solution B at a constant speed. After standing for 10 seconds, the solution will automatically separate into layers, seal the reaction system, and stand at 10°C for 15 days. TAPB-BPTA-COFs film material was generated in situ on the glass bottle wall. The reaction system and reaction process for preparing TAPB-BPTA-COFs film are as follows: figure 1 shown;

[0061] (3) Pour off the reactio...

Embodiment 2

[0076] (1) Using a 50mL glass bottle as a reaction vessel, dissolve p-azidobenzoic acid (N 3 -Ph-COOH), ascorbic acid (AA) and anhydrous CuSO 4 .

[0077](2) Place the TAPB-BPTA-COFs@PVDF membrane obtained above in a 3 -Ph-COOH solution system soaked for 2 to 4 hours, and then dissolved in ascorbic acid (AA) and anhydrous CuSO 4 The solution is fully mixed and added to the solution system of the azide compound, and the reaction temperature is controlled by a constant temperature oscillator, and the reaction time is 12 hours. This post-synthetic modification strategy is as Figure 7 shown.

[0078] (3) After the reaction, the COFs film was clamped out from the solution, soaked and washed with tetrahydrofuran for 3 to 5 times, and then dried under vacuum at 60°C for more than 12 hours to obtain COFs@PVDF-N 3 -Ph-COOH.

[0079] (4) Soak the dried membrane in 0.027mM / mL anhydrous Cu(CH 3 COO) 2 in methanol solution for 24 hours, and then dried under vacuum at 60°C for more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com