A kind of preparation method of high-density polyethylene powder material

A technology of high-density polyethylene and powder materials, applied in the field of powder materials, can solve the problems of reduced resin fusion adhesion, affecting the mechanical strength of products, and low yield of powder materials, etc., to improve resin fusion adhesion , easy to implement, and enhance the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

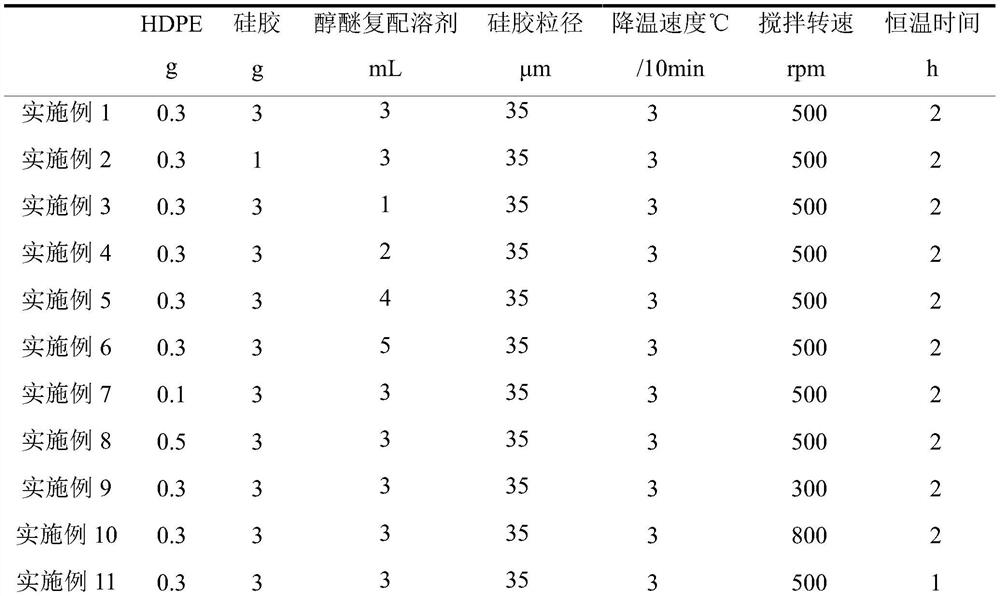

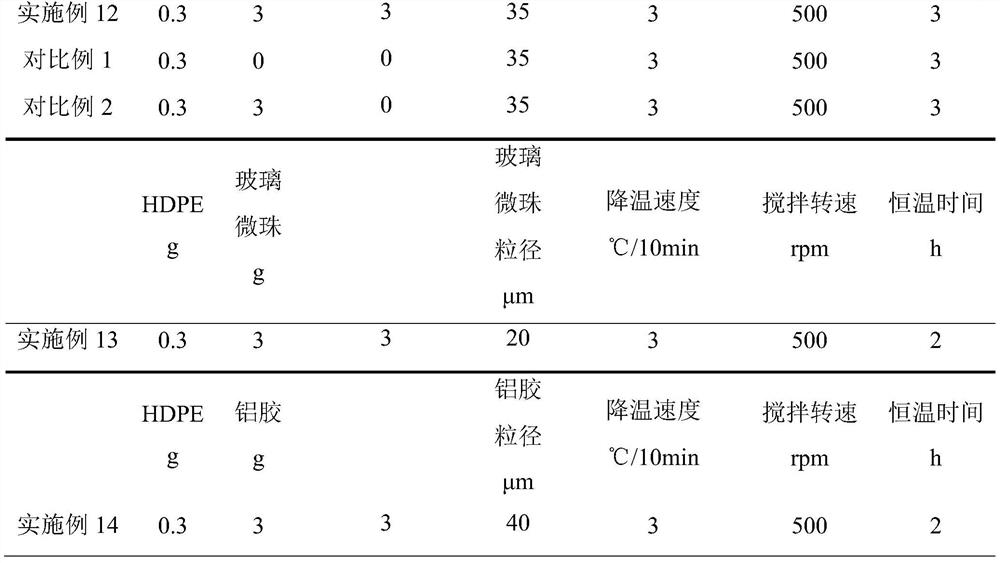

Embodiment 1

[0041] First, a 250 mL three-necked flask with a heating system, a stirring device and a reflux condensing system was replaced with nitrogen for no less than three times, and then 100 mL of decalin and 0.3 g HDPE were added to raise the system temperature to 135 ° C, and at this temperature Keep it for 0.5 hours until HDPE is completely dissolved in decalin; add 3 g of silica gel, the particle size of silica gel is 35 μm, add 3 mL of alcohol ether compound solvent (the mass ratio of absolute ethanol and octylphenol polyoxyethylene ether is 1:1 ), the stirring speed is 500rpm; the system is cooled to 105°C by a program, the cooling rate is 3°C / 10 minutes, and the system is kept at a constant temperature of 105°C for 2 hours. Finally, stop stirring, let stand, suck out the supernatant, wash with hexane three times, and vacuum dry to obtain powder material. The specific formula and process conditions of the embodiment are shown in Table 1, and the properties of the powder materia...

Embodiment 2

[0043] The powder material was prepared by the same method as in Example 1, but in the preparation process, the amount of silica gel was changed from 3 g to 1 g. The specific formula and process conditions of the embodiment are shown in Table 1, and the properties of the powder material are shown in Table 2.

Embodiment 3

[0045] The powder material was prepared by the same method as in Example 1, but in the preparation process, the amount of the alcohol-ether compound solvent was changed from 3 mL to 1 mL. The specific formula and process conditions of the embodiment are shown in Table 1, and the properties of the powder material are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com