Method for treating high-COD wastewater containing heavy metals

A technology for wastewater treatment and heavy metals, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

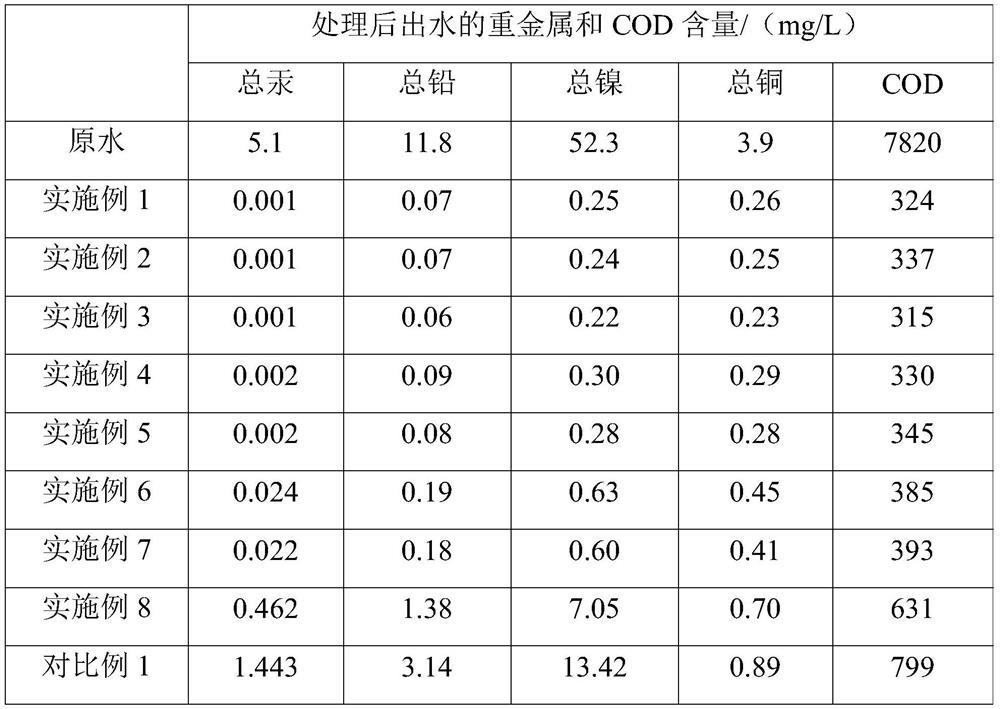

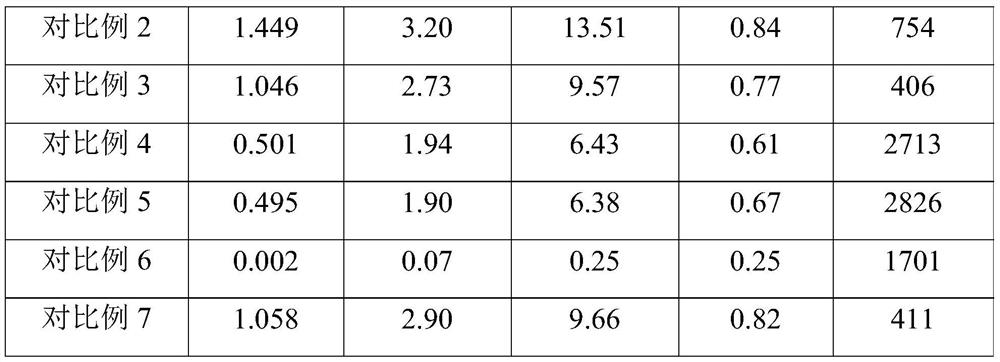

Examples

Embodiment 1

[0048] (1) discharge the waste water into the regulating tank, and adjust the pH value of the waste water to 7.2;

[0049] (2) After the step (1) is processed, the waste water flows into the reaction pool. The butanediamine polyamide amine blocked by sodium dithiocarboxylate is 50 mg per L of waste water, and 30 mg per L of waste water for sodium dimethyl dithiocarbamate. Add and stir for 8 minutes, then add iron polysilicate at 1000 mg per L of wastewater and stir for 4 minutes, then add cationic polyacrylamide with a cationic degree of 40% at 7 mg per L of wastewater, and continue stirring for 4 minutes;

[0050] (3) After the step (2) is processed, the mixed solution flows into the sedimentation tank for sedimentation and separation. The residence time is 6min. 35% of the floc precipitation in the lower floor obtained by the sedimentation separation is returned to the reaction tank, and the remaining flocs are concentrated and then filtered. Buried, the floc concentrated su...

Embodiment 2

[0054] (1) discharge the waste water into the regulating tank, and adjust the pH value of the waste water to 7.8;

[0055] (2) After the step (1) is processed, the waste water flows into the reaction pool. The ethylenediamine polyamide amine end-capped by ammonium dithiocarboxylate is charged at 70 mg per L of waste water, and dimethyl dithiocarbamate is used at the rate of per L of waste water. Add 50 mg and stir for 16 minutes, then add polyferric sulfate (Qinyang Lebang Water Treatment Material Co., Ltd., Lebang Polymerized Ferric Sulfate SPFS) at 1500 mg per L of wastewater and stir for 8 minutes, then add 9 mg per L of wastewater Cationic polyacrylamide with a cationic degree of 50%, continue to stir and react for 7 minutes;

[0056] (3) After the step (2) is processed, the mixed solution flows into the sedimentation tank for sedimentation and separation. The residence time is 9min. 50% of the floc precipitation in the lower layer obtained by the sedimentation separation ...

Embodiment 3

[0060] (1) discharge the waste water into the regulating tank, and adjust the pH value of the waste water to 7.5;

[0061] (2) After the step (1) is processed, the waste water flows into the reaction pool. The hexamethylenediamine core polyamide amine blocked by potassium dithiocarboxylate is 60 mg per L of waste water, and potassium dimethyl dithiocarbamate is used per L of waste water. Add 40 mg and stir for 12 minutes, then add polysilicate ferric sulfate at 1200 mg per L of wastewater and stir for 6 minutes, then add cationic polyacrylamide with a cationic degree of 50% at 8 mg per L of wastewater, and continue stirring for 6 minutes;

[0062] (3) after the step (2) is processed, the mixed solution flows into the sedimentation tank for sedimentation and separation, and the residence time is 7min. 45% of the floc precipitation in the lower floor obtained by the sedimentation separation is returned to the reaction tank, and the remaining flocs are concentrated and then filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com