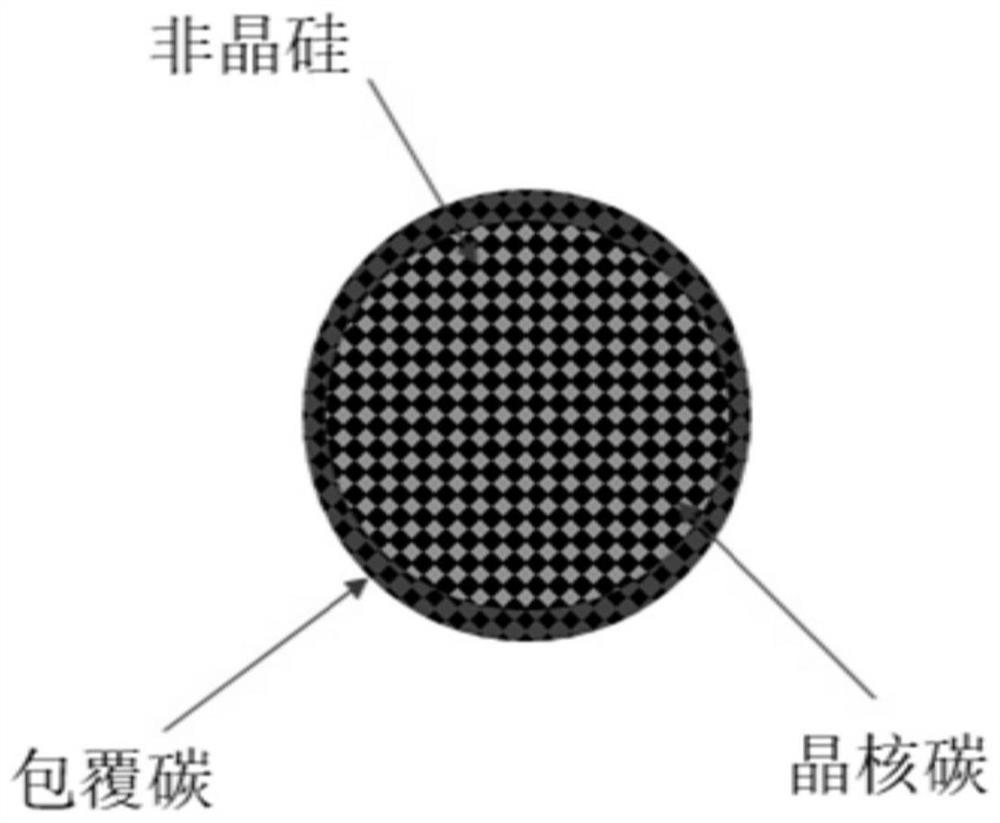

Nano-amorphous c-si-c composite material and its manufacturing method and manufacturing device

A nano-amorphous, composite material technology, applied in nano-carbon, nano-technology, nano-technology and other directions, can solve problems such as pole piece cracking, and achieve the effect of good conductivity and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

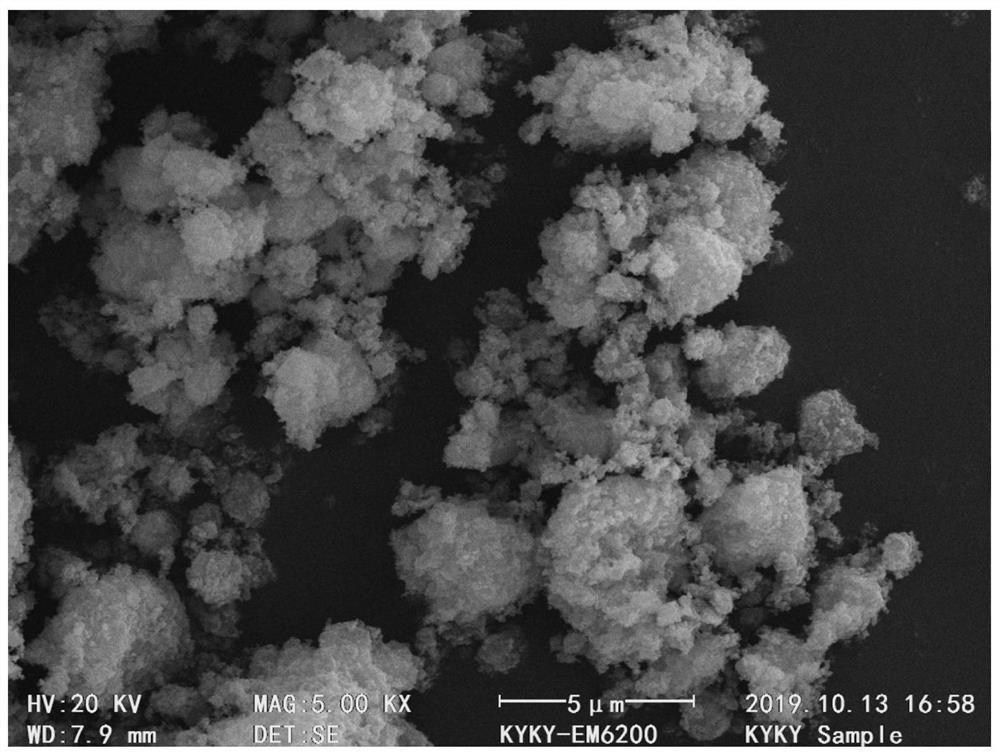

Examples

Embodiment 1

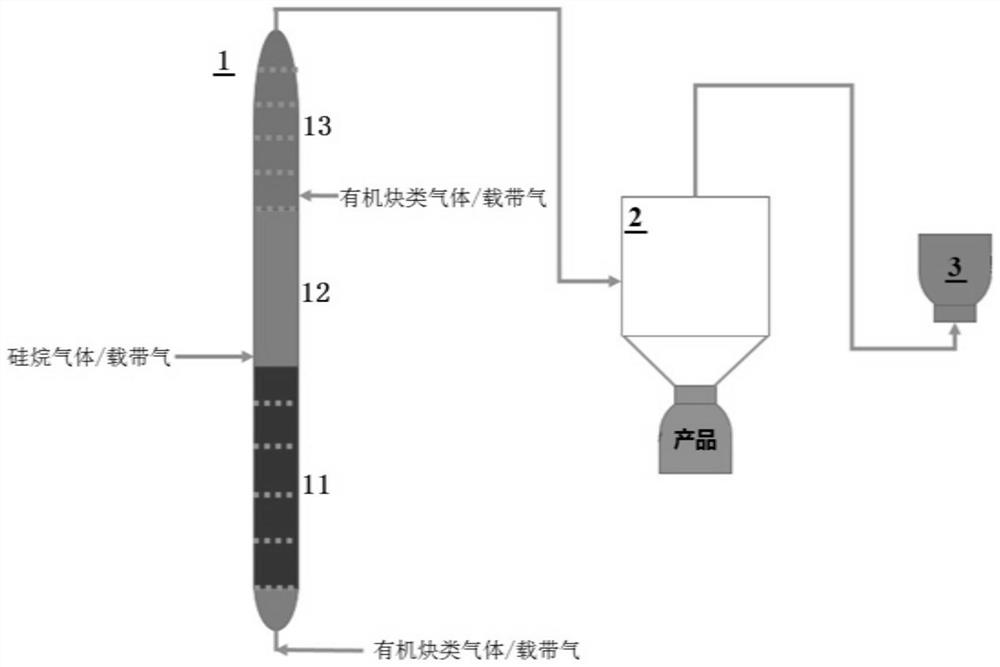

[0057] A 304 stainless steel tube with an inner diameter of 60mm was used as the cracking tube of the gas-phase cracking unit, and a heating tape was wound on the outside, and the temperature was programmed and controlled. Since the cracking of alkynes and silanes are both exothermic reactions, in order to effectively control the temperature of the cracking zone, there is no need to set up a thermal insulation jacket on the periphery of the cracking tube, and air cooling can be added if necessary.

[0058] The cracking tubes are placed vertically, and from bottom to top are the first cracking zone, the second cracking zone, and the third cracking zone. The height of the first cracking zone is 2 meters, the height of the second cracking zone is 2.5 meters, and the height of the third cracking zone is 1.5 meters. The three-way intake is set on the bottom side of the three areas, and the flared air outlet. Five layers of Cu / Co / Ni / MgO / TiO are arranged horizontally and equally in ...

Embodiment 2

[0064] A 304 stainless steel tube with an inner diameter of 100mm was used as the cracking tube of the gas-phase cracking unit, and the heating tape was wound on the outside, and the temperature was programmed and controlled. Since the cracking of alkynes and silanes are both exothermic reactions, in order to effectively control the temperature of the cracking zone, there is no need to set a thermal insulation jacket on the periphery of the cracking tube, and air cooling can be added if necessary.

[0065] The cracking tubes are set horizontally, from left to right are cracking zone one, cracking zone two and cracking zone three. The length of the first cracking zone is 2.5 meters, the length of the second cracking zone is 3 meters, and the length of the third cracking zone is 2 meters. The first intake air is arranged on the left side of the first cracking zone, the second intake air is placed at the lower left side of the second cracking zone, the third intake air is placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com