Automobile seat headrest

A technology for car seats and headrests, applied in vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problem of high cost of headrests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

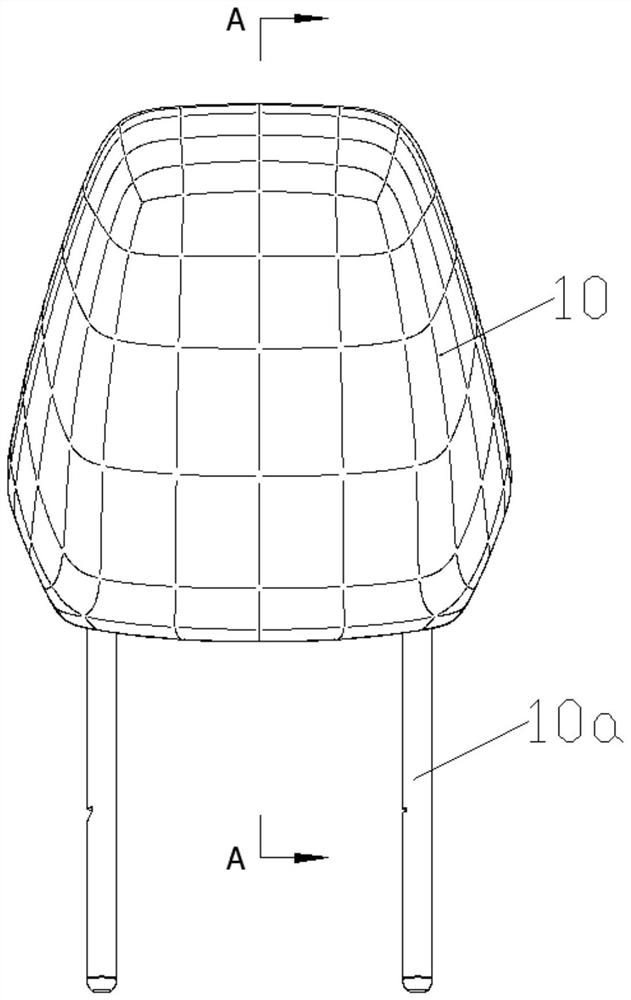

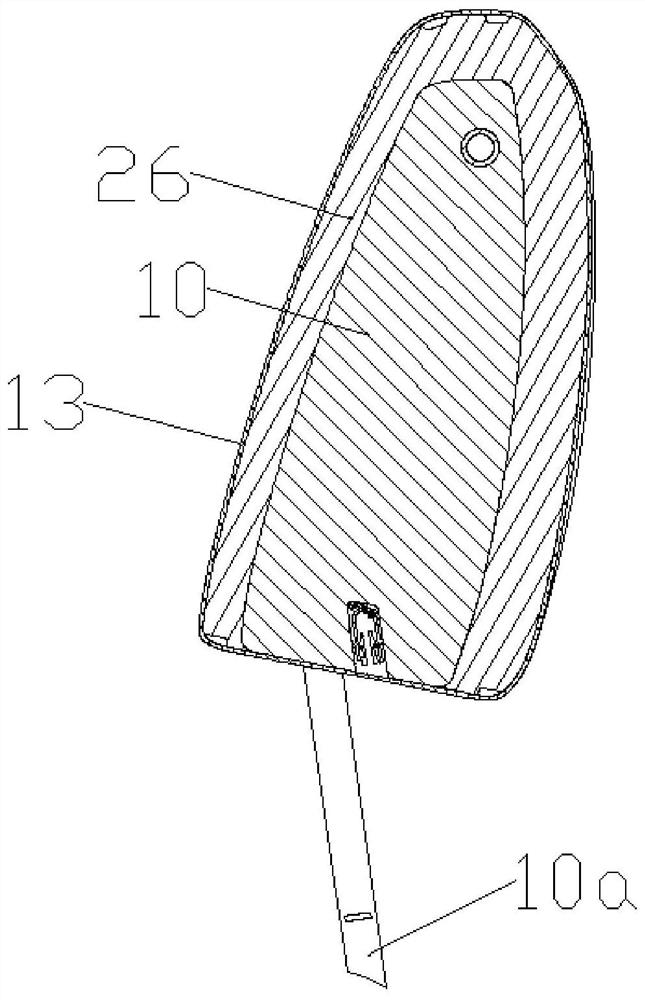

[0050] Such as Figure 1-2 As shown, the present embodiment provides a headrest for a car seat, which includes: a base module 10 made of expanded polypropylene material (EPP), and the base module 10 is adjustable in height through a headrest rod 10a on the seat back. The base module 10 is wrapped sequentially with polyurethane foam 12 and body cover 13 from the inside to the outside.

[0051] The basic module of the headrest in the present invention is made of EPP, which has better impact resistance and cushioning capacity, lighter weight and more beneficial safety performance.

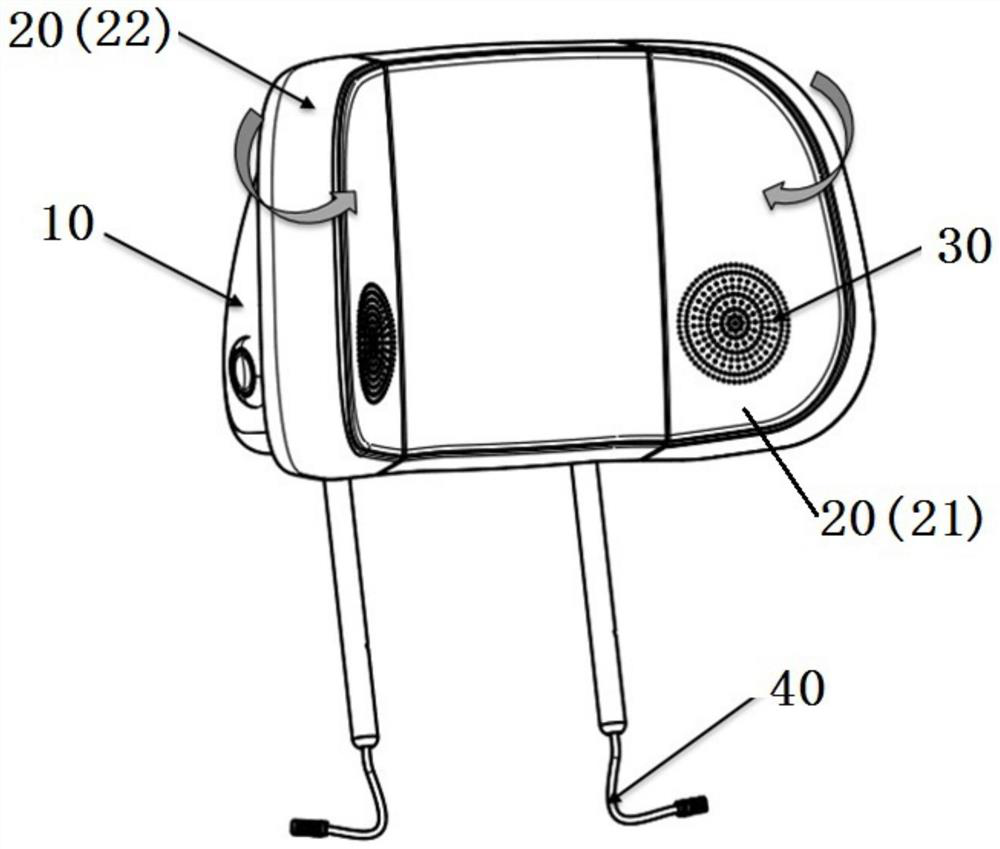

[0052] In the above technical solutions, more preferably, as image 3 As shown, a wing part 20 may also be included, and the wing part 20 is arranged on the base module 10, and a speaker 30 is arranged on the wing part 20;

[0053] The wing part 20 is divided into a left wing part 21 and a right wing part 22; the left wing part 21 and the right wing part 22 are respectively provided with a speaker ...

Embodiment 2

[0069] This embodiment is basically the same as Embodiment 1, the difference is:

[0070] Such as Figure 11 As shown, the car seat headrest disclosed in this embodiment has an actuator module 100 for maintaining and changing the swing angle of the wings.

[0071] The execution module 100 in this embodiment is set on the base module 10 ; or, there is an installation space left on the base module 10 , and the execution module 100 is set on the middle fixing plate 50 .

[0072] The execution module 100 includes: a cylindrical body 110 , a first push rod 120 , a second push rod 130 and a rack-and-pinion transmission pair 140 . The cylindrical body 110 is generally arranged along the front-rear direction of the vehicle body. The top ends of the first push rod 120 and the second push rod 130 are inserted into the cylindrical body 110 from the front and rear ends respectively. The middle through hole of the shape body 110 slides.

[0073] The rack and pinion transmission pair 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com