Plastic uptake molding method for plastic packaging box and plastic uptake mold

A technology of blister forming and blister mould, applied in the field of blister mould, which can solve the problems of prone to stripes and uneven thickness, large material waste, and low production efficiency, so as to increase hand feeling and smoothness, and fast molding speed , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

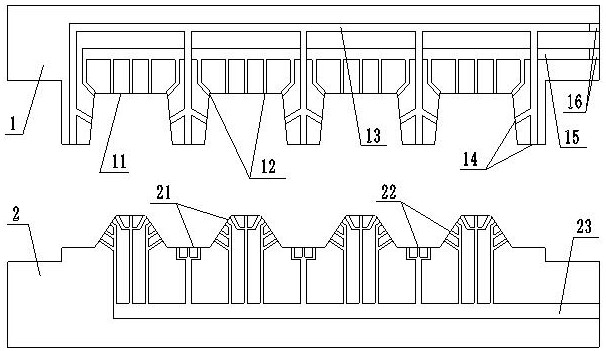

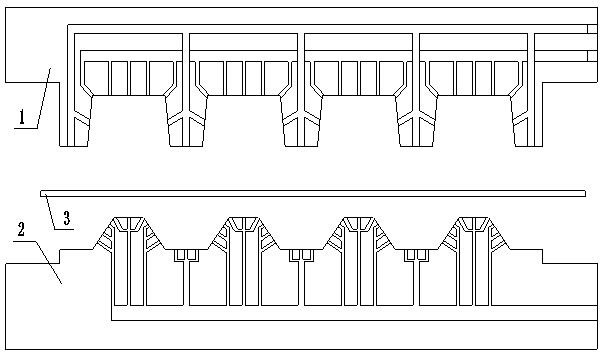

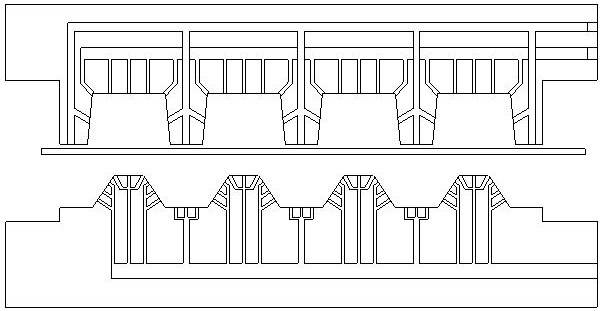

[0035] like Figure 2 to Figure 4 As shown, a method of blister molding using the above-mentioned blister mold for plastic packaging boxes, the molding method mainly includes taking materials, softening, feeding, vacuuming, cooling and setting, demolding and cutting molding, specifically including The following steps:

[0036] (1) taking material: select to be used to prepare the plastics of plastic packing box and make as plastic sheet 3, the thickness of plastic sheet 3 is 1mm;

[0037] (2) Softening: transport the prepared plastic sheet 3 to the heating equipment for heating, and adopt a three-stage gradient heating method for heating. The specific process conditions are as follows. The heating time of the first stage is 80-90 seconds, and then the second stage heating is carried out at a temperature of 180-190°C, and the heating time is 50-60 seconds, and finally the third stage is carried out at a temperature of 240-250°C. Step heating, the heating time is 30-40 seconds...

Embodiment 2

[0044] like Figure 2 to Figure 4 As shown, a method of blister molding using the above-mentioned blister mold for plastic packaging boxes, the molding method mainly includes taking materials, softening, feeding, vacuuming, cooling and setting, demolding and cutting molding, specifically including The following steps:

[0045] (1) taking material: select to be used to prepare the plastics of plastic packing box and make as plastic sheet 3, the thickness of plastic sheet 3 is 2mm;

[0046] (2) Softening: Transport the prepared plastic sheet 3 to the heating equipment for heating, and adopt a three-stage gradient heating method for heating. The specific process conditions are as follows. The first stage of heating, the heating time is 70-80 seconds, and then the second stage heating is carried out at a temperature of 190-200°C, and the heating time is 45-55 seconds, and finally the third stage is carried out at a temperature of 250-260°C. Step heating, the heating time is 25-3...

Embodiment 3

[0053] like Figure 2 to Figure 4 As shown, a method of blister molding using the above-mentioned blister mold for plastic packaging boxes, the molding method mainly includes taking materials, softening, feeding, vacuuming, cooling and setting, demolding and cutting molding, specifically including The following steps:

[0054] (1) taking material: select to be used to prepare the plastics of plastic packing box and make as plastic sheet 3, the thickness of plastic sheet 3 is 3mm;

[0055] (2) Softening: Transport the prepared plastic sheet 3 to the heating equipment for heating, and adopt a three-stage gradient heating method for heating. The specific process conditions are as follows. The heating time of the first stage is 60-70 seconds, and then the second stage heating is carried out at a temperature of 200-210°C, and the heating time is 40-50 seconds, and finally the third stage is carried out at a temperature of 260-270°C. Step heating, the heating time is 20 to 30 seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com