Glass mobile phone rear cover plate one-step pressure forming all-electric melting glass furnace and method

A technology for mobile phone back cover and molding, applied in glass furnace equipment, electric furnace, glass manufacturing equipment, etc., can solve the problems of difficult to form homogenized glass liquid, glass is at high temperature, unable to eliminate glass liquid streaks, etc., and achieve the production process. Simple and stable, easy to process and shape, simple transformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

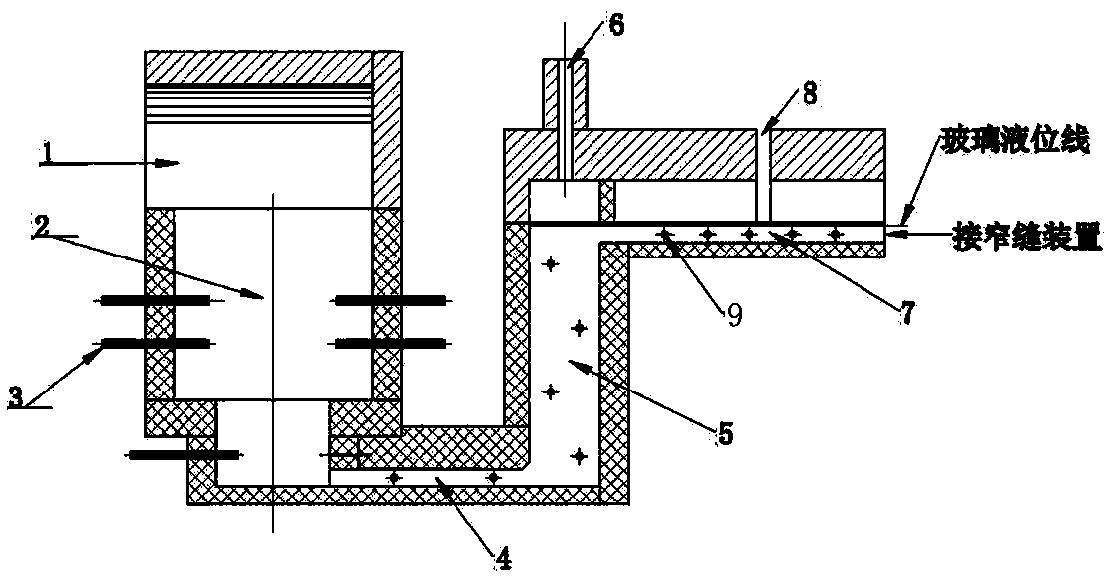

[0030] like figure 1 As shown, the rear cover of the glass mobile phone is once molded into a fully electric fused glass furnace. The furnace is made of refractory bricks and includes a glass melting device 2 arranged vertically. The inner wall of the glass melting device 2 is fixed with an electric A heating and melting device 3, a feeding device 1 is installed on the top of the glass melting device 2, a horizontally arranged feed channel 4 is connected to the bottom of the glass melting device 2, and a vertically upwardly arranged secondary equalizer is connected to the other end of the feed channel 4. The clarification device 5, the top of the secondary homogenization and clarification device 5 is connected to the horizontal glass liquid conveying device 7, and the connection between the secondary homogenization and clarification device 5 and the glass liquid conveying device 7 is provided with a vacuum device 6, and the glass liquid conveying device The inner wall of 7 is ...

Embodiment 2

[0033] A method for producing fully fused glass by one-time compression molding of the back cover of a glass mobile phone, characterized in that it includes the following steps:

[0034] Step 1) Raw material feeding: first use the electric heating melting device (3) to raise the inner furnace temperature of the glass melting device (2) to above 800°C, and use the feeding device (1) to start feeding the mixture when the furnace temperature rises to above 850°C , the raw material components of the mixture include silica, boria, aluminum oxide, calcium oxide, sodium oxide, magnesium oxide, zinc oxide, zirconium dioxide, and the mixture is in parts by weight, and the raw material components include: 60 parts of silicon, 2 parts of boron oxide, 18 parts of aluminum oxide, 0.5 parts of calcium oxide, 15 parts of sodium oxide, 6 parts of magnesium oxide, 2 parts of zinc oxide, 2.5 parts of zirconium dioxide;

[0035] Step 3) Raw material melting: Use the electric heating melting devi...

Embodiment 3

[0039] The mixture is calculated in parts by weight, and the raw material components include: 65 parts of silicon dioxide, 2 parts of boron oxide, 18 parts of aluminum oxide, 0.5 part of calcium oxide, 15 parts of sodium oxide, 6 parts of magnesium oxide, 2 parts of zinc oxide, 2.5 parts of zirconium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com