An integrated storage and handling device for plate processing

A plate processing and integrated technology, applied in the field of plate processing, can solve the problems of bulky metal plates and labor-intensive, etc., and achieve the effects of avoiding excessive extrusion force, improving stability, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

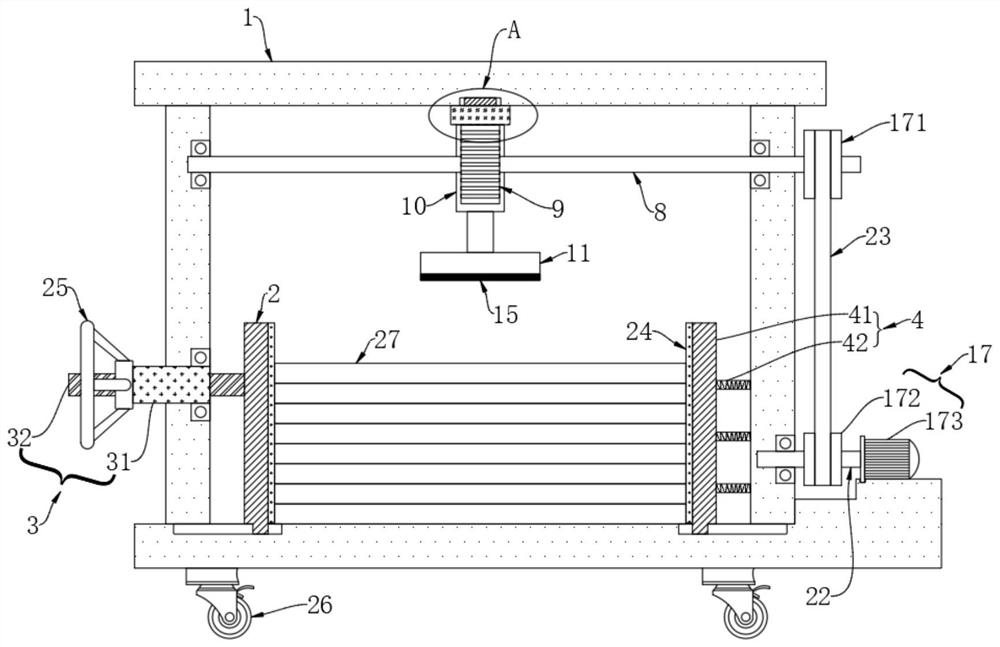

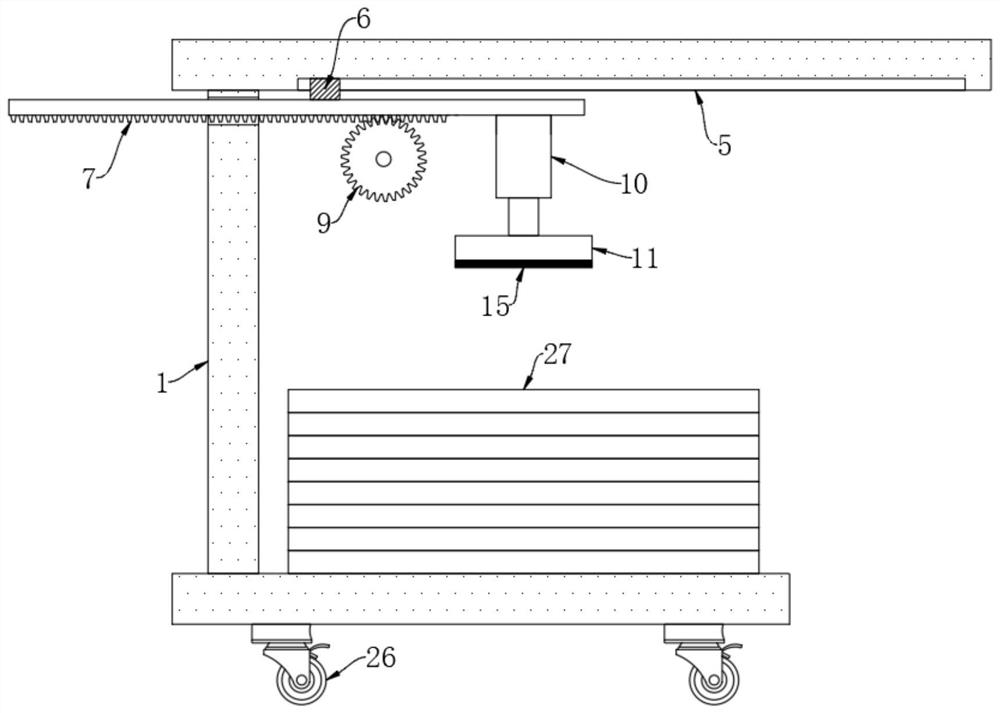

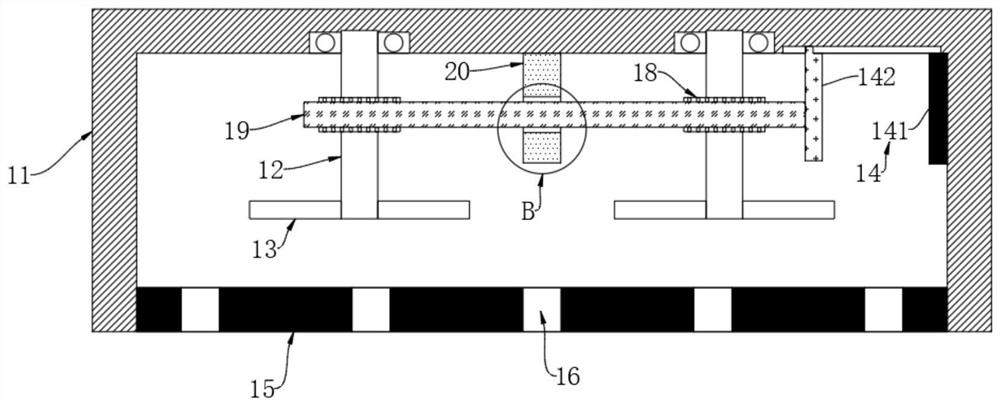

[0032] Such as Figure 1-5 As shown, a storage and transportation integrated device for plate processing includes a storage rack 1, a plurality of universal wheels 26 are fixedly connected to the lower end side wall of the storage rack 1, and the universal wheels 26 are self-locking, and the setting of the universal wheels 26 , which is convenient for the user to move the whole device. The storage rack 1 is slidably connected with the backing plate 2, and the storage rack 1 is provided with a stabilizing mechanism 3 matched with the backing plate 2. The stabilizing mechanism 3 includes a threaded sleeve 31 and a screw rod 32. The threaded sleeve 31 is rotatably connected to the storage rack 1, the screw rod 32 is threadedly connected in the threaded sleeve 31, and one end of the screw rod 32 is fixedly connected with the abutment plate 2, and the movement of the abutment plate 2 can be regulated through the set threaded sleeve 31 and the screw rod 32, so that the abutment plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com