Efficient working and automatic heating forging device based on servo motor

A technology of servo motor and automatic heating, applied in the field of servo motor, can solve the problems of wasting manpower, poor forging effect, scalding staff, etc., and achieve the effect of labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

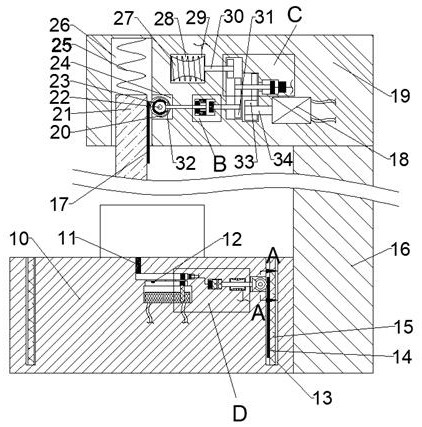

[0017] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

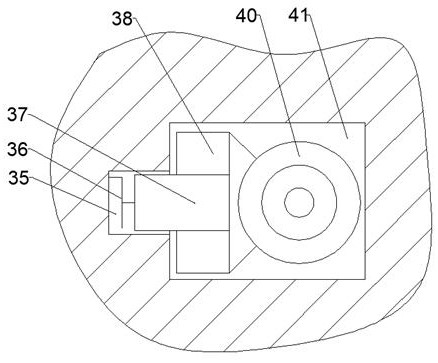

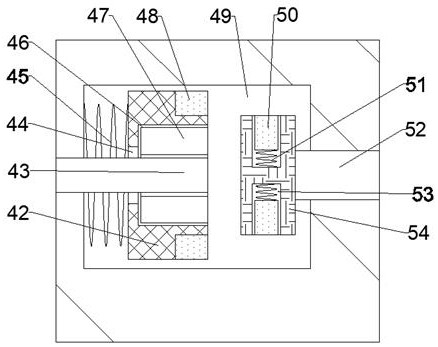

[0018] A high-efficiency and automatic heating forging device based on a servo motor described in conjunction with accompanying drawings 1-5 includes a main box 10, and the main box 10 is provided with an electromagnetic heating cavity 13 with an upward opening and a ring arrangement. The inner side of the electromagnetic heating chamber 13 is communicated with a rack and pinion chamber 41, the rear side of the rack and gear chamber 41 is communicated with a rack and pinion shaft chamber 35, and the left side of the rack and gear chamber 41 is provided with an auxiliary wire wheel chamber 83 The left side of the auxiliary wire wheel chamber 83 is provided with a limiting wheel chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com