A large-span liftable variable deflection cantilever throwing device

A cantilever rod, large-span technology, applied in the direction of the spray device, etc., can solve the problems of small coating space, poor coating quality stability, low coating efficiency, etc., to achieve small cantilever deflection deformation, light weight, and offset extrusion damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in conjunction with the examples.

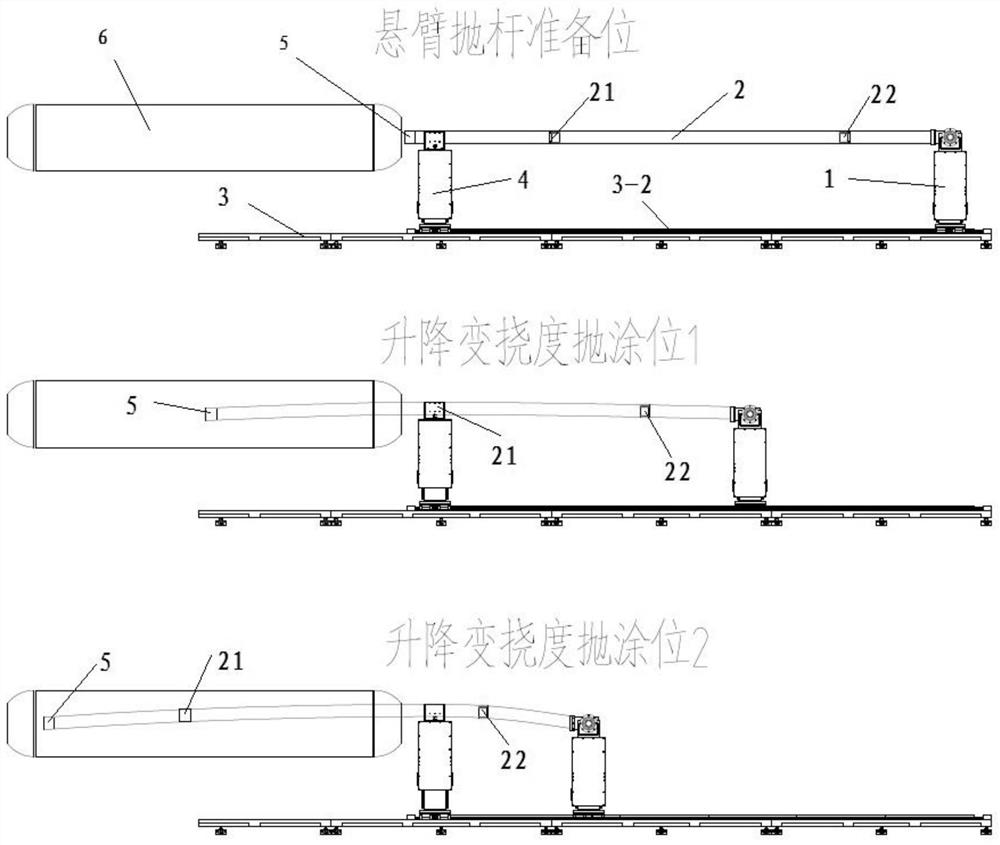

[0026] In order to overcome the shortcomings of the existing manual ultra-long rod coating process in terms of poor coating quality and low coating efficiency, and to solve the contradiction between the size of the coating device itself and the size of the engine casing to be coated, the present invention designs a A large-span liftable variable deflection cantilever throwing device, which can flexibly expand and contract in small spaces of different lengths and different diameters of engine casings while taking into account the coating quality and efficiency, thereby solving the problem of the prior art. problems in .

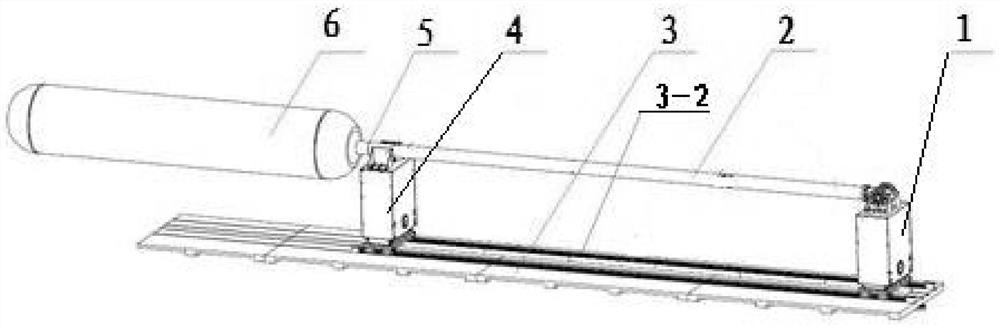

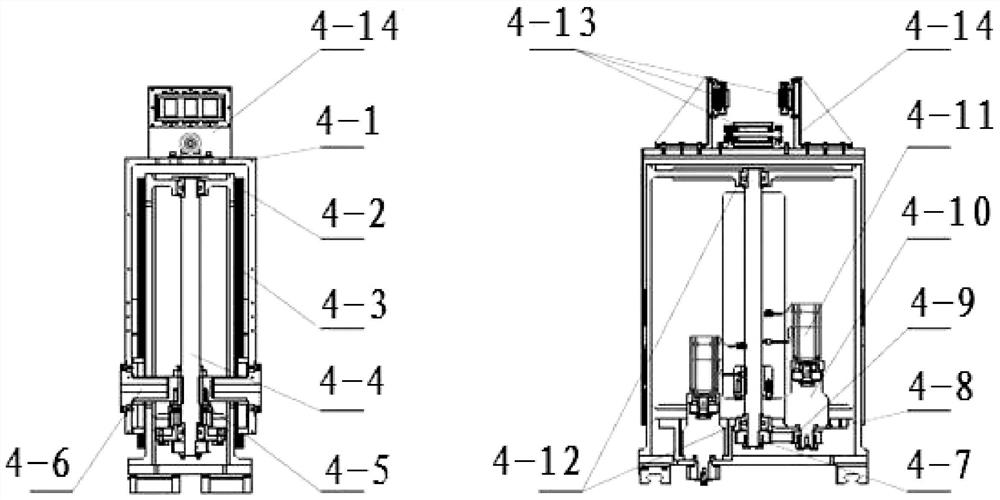

[0027] Large-span liftable variable-deflection cantilever throwing device, such as figure 1 As shown, it specifically includes a mobile end lifting group module 1, a cantilever rod 2, a platform base 3, a fixed end lifting group module 4, an end coating device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com