A kind of preparation method of prestressed basalt fiber board composite wooden beam

The technology of basalt fiber board and basalt fiber cloth is applied in the field of preparation of composite wood beams, which can solve the problems of low utilization rate of short wood materials, unreasonable use of wood, large amount of wood, etc., and achieves good environmental protection benefits, easy control of application precision, large span effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

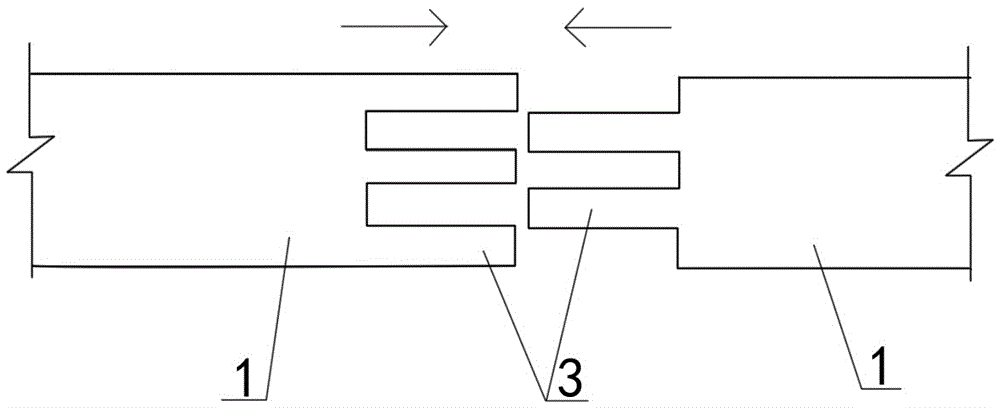

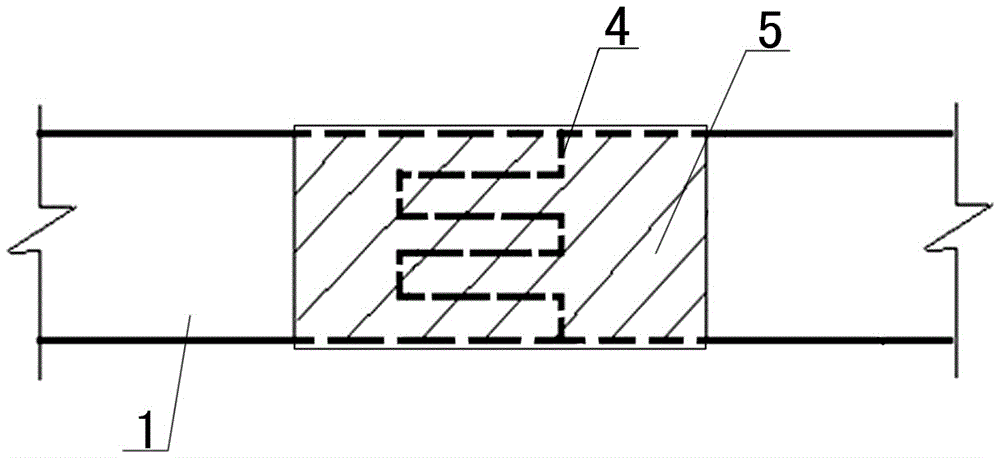

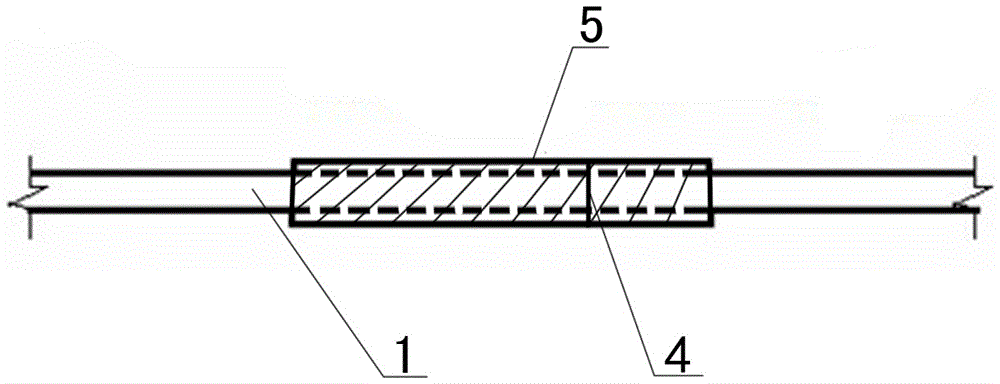

[0037] Examples see Figure 1~2 As shown, a prestressed basalt fiberboard composite wooden beam is a composite beam formed by bonding multi-layer boards, including a wooden board 1 and a basalt fiberboard 2, and the same-layer wooden boards of the composite beam are spliced along the length direction of the wooden boards to form a In one piece, two layers of wood boards adjacent to each other along the thickness direction of the wood boards are spliced by adhesive glue, and the splicing parts need to be staggered, see image 3 As shown, a basalt fiber cloth 5 is bonded outside the joint.

[0038] see Figure 4~5 As shown, the basalt fiber board 2 is arranged along the length direction of the composite beam, and is bonded to both sides of the outermost wood board 1.1 of the composite beam, which are respectively the first basalt fiber board 2.1 on the inside of the board and the second basalt fiber board on the outside of the board 2.2,

[0039] The second basalt fiber b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com