Heating plant core and smoking product comprising same

A technology of plants and plant materials, applied in food science, cigar manufacturing, application, etc., can solve the problems of poor aroma stability and coordination of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

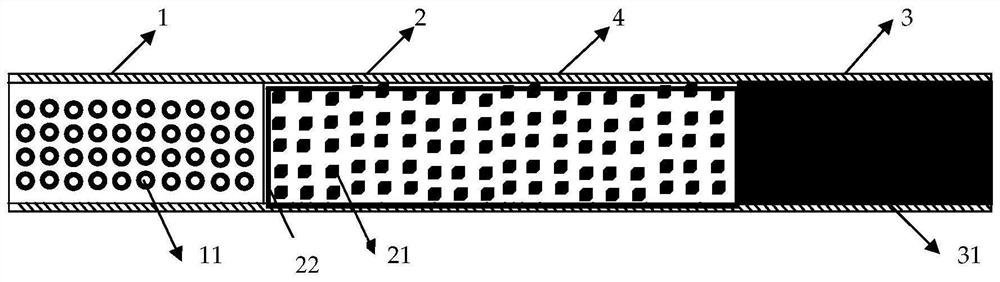

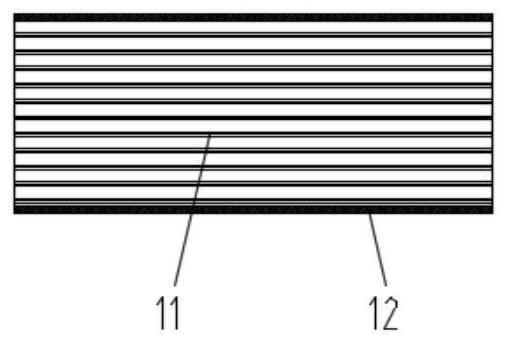

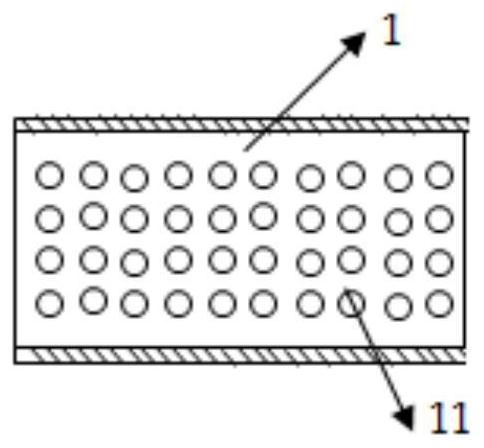

[0067] Plant core structure hollow tube 4 is molding paper (gram weight 45g / m 2 ordinary paper), the inner diameter is 8mm, and the length is 50mm; the filter unit 3 is polylactic acid fiber tow, and the length is 15mm; , the tea stalk particles are loaded with 25% (percentage is based on the total weight of tea stalks) low-boiling limonene essence (boiling point 177°C); the wrapper 22 is a paper tube with openings at both ends of the paper tube (gram weight 80g / m 2 white paper), the length is 15mm, and the outer diameter is 8mm. The tea stem particles are wrapped by paper tubes, and the two ends are sealed with non-woven fabrics; and high-boiling-point flavanone flavor (boiling point 386.2°C) as raw materials to prepare and process a shaped cylinder with an outer diameter of 8mm, and the forming paper 12 wrapped with the fuming mixture 11 is food-grade tipping paper with a grammage of 40g / m 2 . A heating plant core is obtained by ternary composite assembly of the above unit...

Embodiment 2

[0069] It is basically the same as in Example 1, the only difference is that the essence added in the aroma producing unit 1 is replaced with the boiling point ambergol essence (boiling point is 495.3°C)

Embodiment 3

[0071] It is basically the same as Example 1, the only difference being that the essence added in the aroma-enhancing product 1 is replaced with a boiling point of citronellol essence (boiling point is 108° C.)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com