Strip-shaped feed processing device

A technology of feed processing and strips, which is applied in the field of strip feed processing devices, can solve the problems of affecting the capacity of feed bags, bending, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

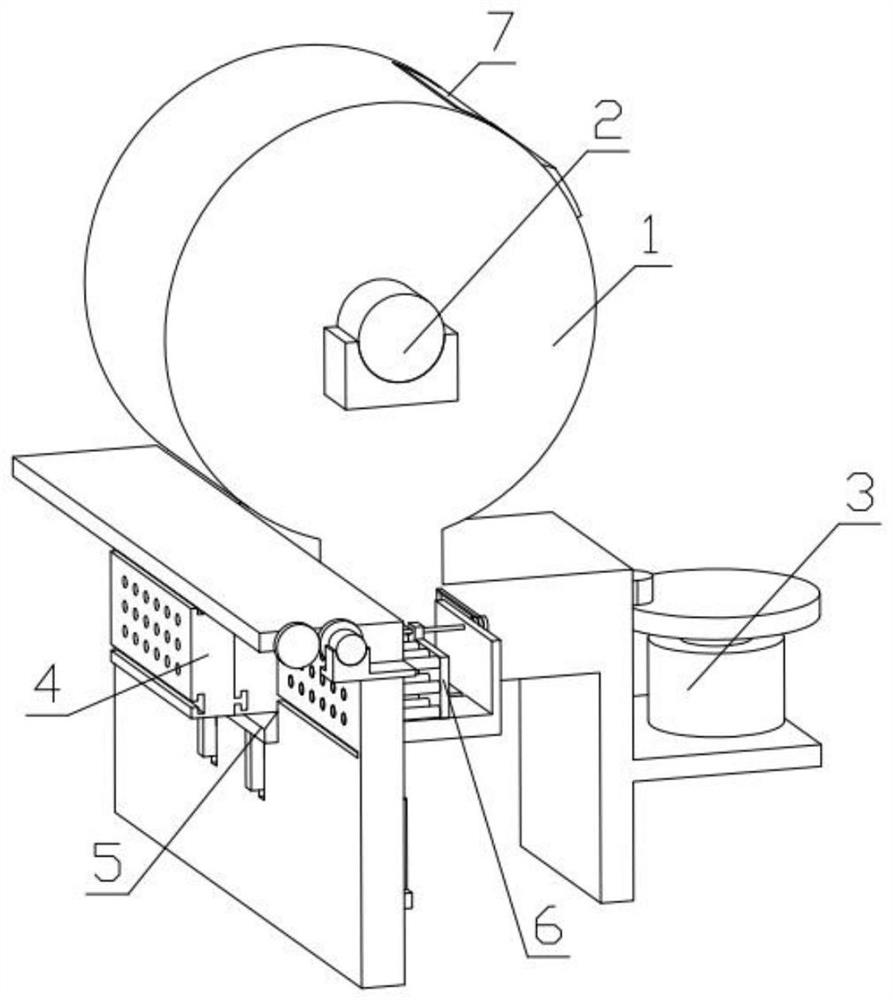

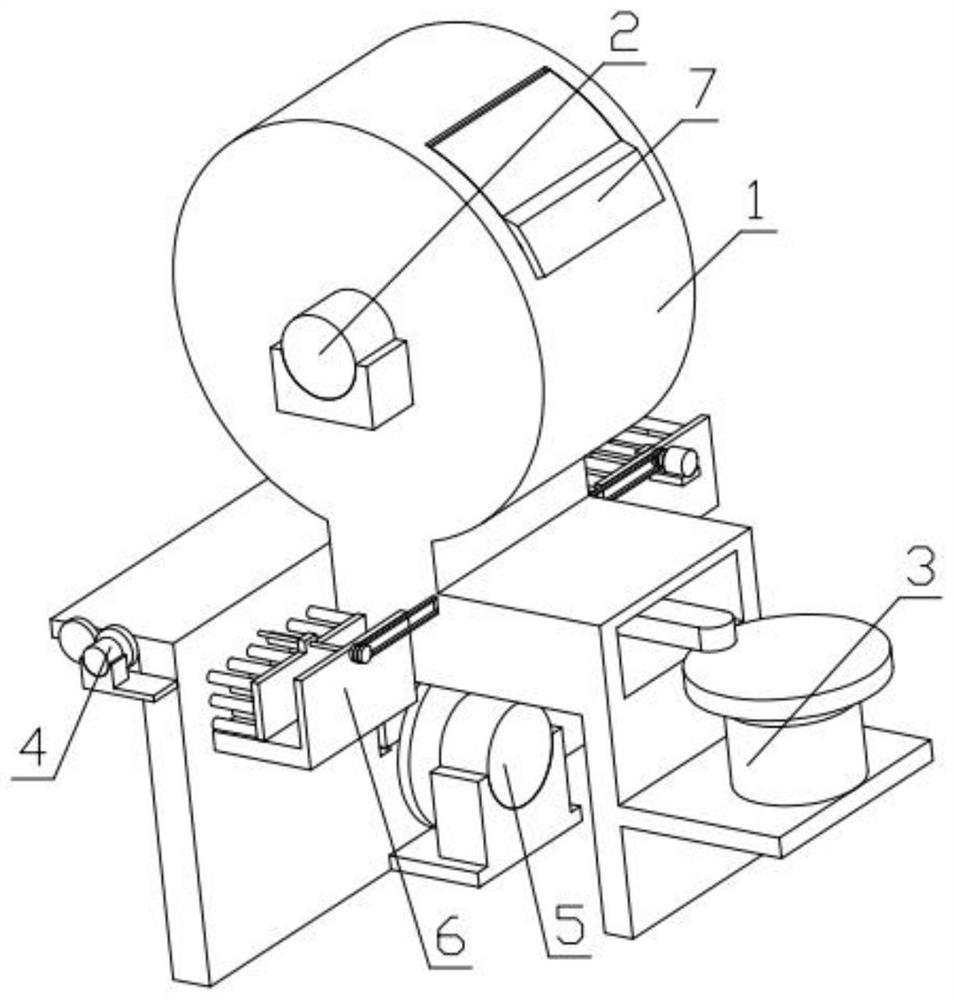

[0033] Combine below Figure 1-12Describe this embodiment, a strip feed processing device, including a main frame 1, a stirring and wall cleaning mechanism 2, a material pushing mechanism 3, a misalignment adjustment mechanism 4, a conventional cutting mechanism 5, a long grain anti-bending mechanism 6 and a sealed door 7 , the airtight door 7 is installed on the main frame 1, the stirring and wall cleaning mechanism 2 is fixedly installed on the main frame 1, the pushing mechanism 3 is fixedly installed on the main frame 1, and the misalignment adjustment mechanism 4 is fixedly installed on the main frame 1 , the conventional cutting mechanism 5 is fixedly installed on the main frame 1, and the long-grain anti-bending mechanism 6 is fixedly installed on the main frame 1.

specific Embodiment approach 2

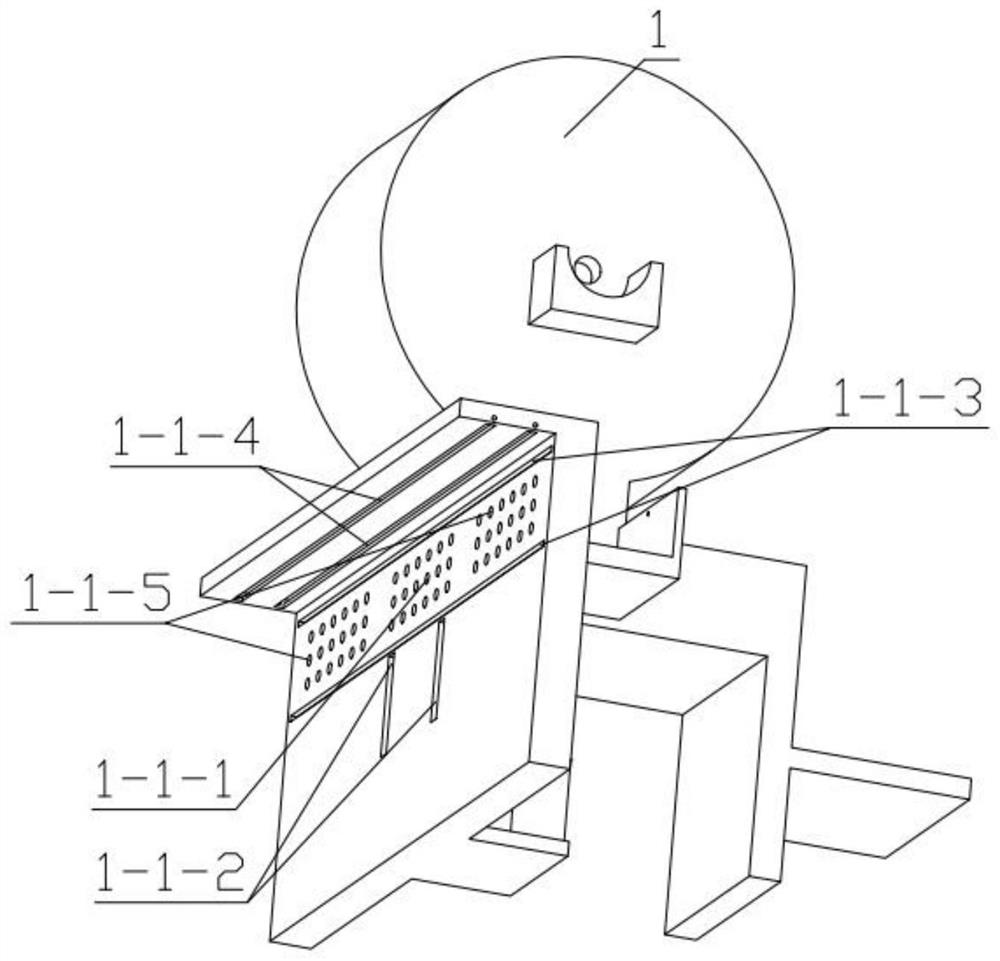

[0035] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the main frame 1 includes the installation of the main frame 1-1, the folding door 1-2, the triangular scraper 1-3, and the installation on the main frame 1-1 A triangular scraper 1-3 is fixedly installed, and a folding door 1-2 is rotatably installed on the main frame 1-1;

[0036] The main frame 1-1 is equipped with discharge holes 1-1-1, longitudinal rails 1-1-2, transverse rails 1-1-3, top rails 1-1-4, side row holes 1-1- 5.

specific Embodiment approach 3

[0038] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain Embodiment 2. The described stirring and wall cleaning mechanism 2 includes a motor 2-1, a motor shaft 2-2, a side slat 2-3, and an apron pad 2- 4. Rubber triangle 2-5, stirring rod 2-6, two-way output motor 2-7, one end of motor one 2-1 is fixedly installed on the installation main frame 1-1, and the output end of motor one 2-1 is fixedly installed There is a motor shaft 2-2, and the other end of the motor shaft 2-2 is rotatably installed in the groove provided on the main frame 1-1, and a bidirectional output motor 2-7 is fixedly installed in the groove of the motor shaft 2-2, The output end of the bidirectional output motor 2-7 is fixedly equipped with a stirring rod 2-6, the motor shaft 2-2 is fixedly equipped with a side slat 2-3, and the side slat 2-3 is rotatably equipped with a rubber triangle 2-5 , rubber ring pads 2-4 are arranged at the junction of the rubber triangle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com