Feed processing device

A technology for feed processing and transportation, which is applied in feed, household refrigeration equipment, cooling fluid circulation equipment, etc., and can solve problems such as cracks on the surface of pellets, environmental pollution, and indigestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

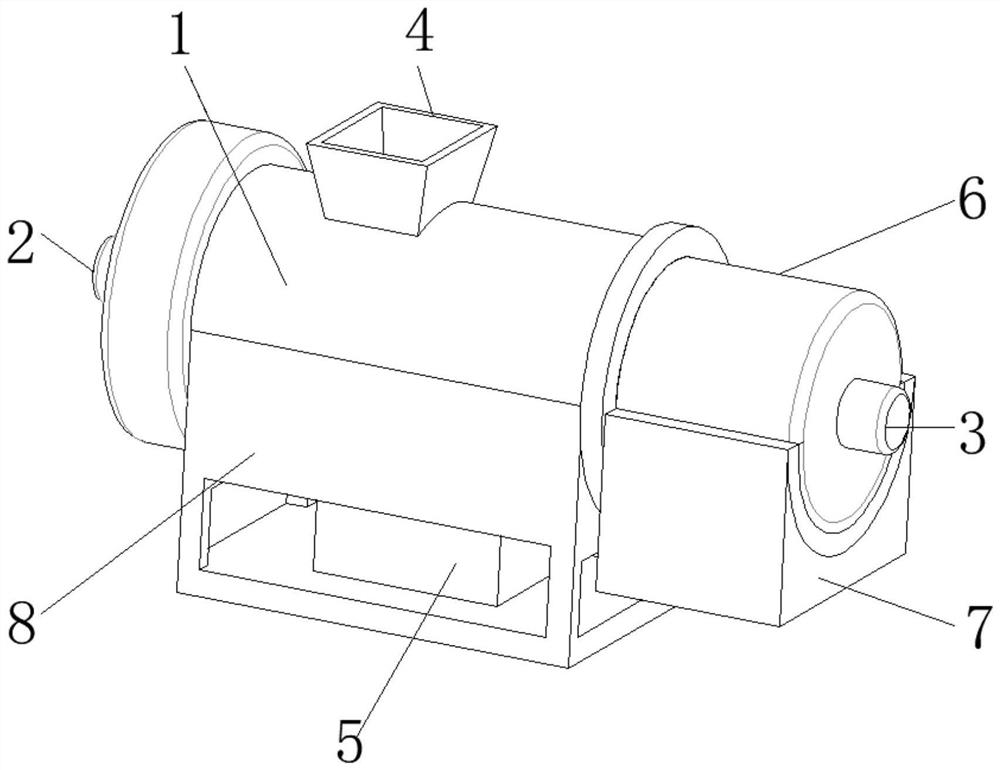

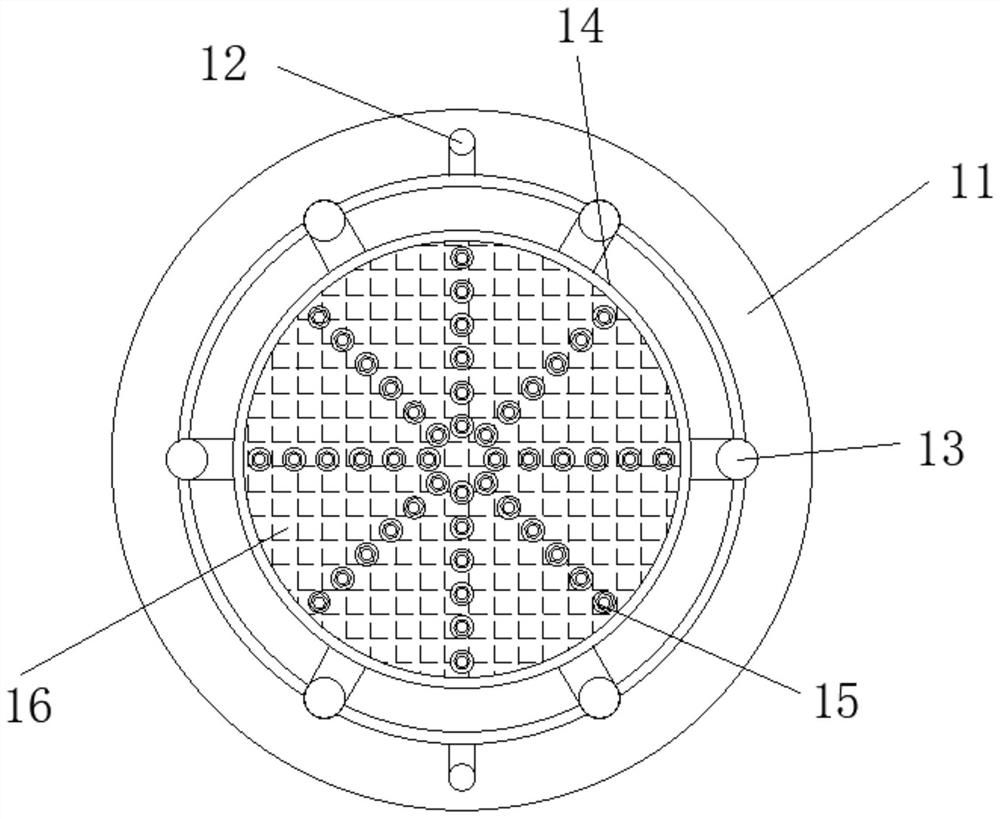

[0029] like Figure 1-6 As shown, the embodiment of the present invention provides a feed processing device, including a feeding pipe 1, a motor a2, a motor b3, a feed hopper 4, a water tank 5, an extruding pipe 6, a pressing mechanism 7 and a support frame 8, and the feeding pipe The outer wall of the top end of 1 is provided with a feeding trough, and the inner wall of the feeding trough is welded to the feeding hopper 4, and the outer wall of one end of the feeding pipe 1 is provided with a motor a2, and the output shaft of the motor a2 is connected with a helical twister through a coupling. Long a9, the outer wall of the bottom end of the feeding pipe 1 is fixedly connected with the support frame 8 by screws, the outer wall of one side of the support frame 8 is movably connected with the water tank 5, the extruding pipe 6 is welded with the feeding pipe 1, and the motor b3 is arranged on the extrusion Press the outer wall of one side of the tube 6, and the output shaft of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com