Optical fiber ultrashort pulse laser system based on flexible transmission output and assembly method of system

A technology of ultra-short pulse laser and flexible transmission, which is applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problem that ultra-fast laser light sources are difficult to achieve flexible transmission output, and achieve easy chassis structure design and avoid nonlinearity Accumulation, volumetric weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

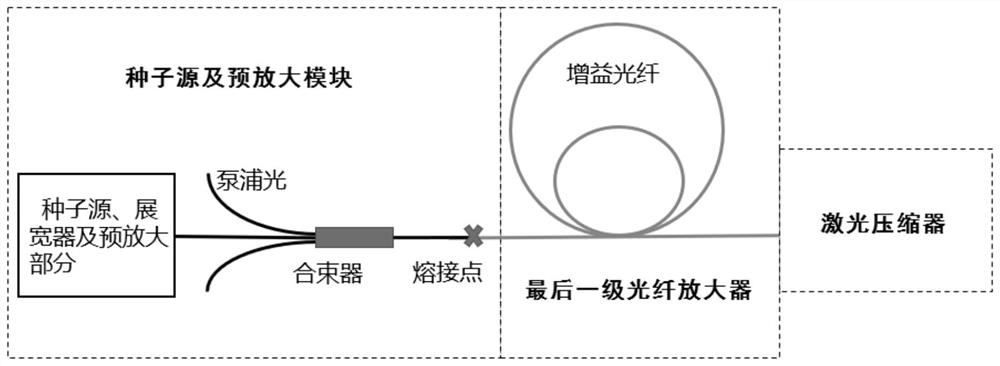

[0024] Fiber ultrashort pulse lasers usually use chirped pulse amplification (CPA), that is, the high repetition rate seed source signal is first stretched by a chirped fiber grating stretcher for pulse time domain stretching, and then injected into a multi-stage fiber amplifier for energy amplification. The modulator reduces the repetition frequency of the laser, and the amplified low-repetition-frequency high-power laser has a large single-pulse energy. The laser signal is finally injected into the laser compressor to compress the pulse width in the time domain, and finally obtain high-power, large-scale Energy, high peak power ultrashort pulse laser output. The entire optical path of the system is usually integrated in a laser head, and the laser is output through an output window through spatial transmission.

[0025] The optical fiber u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com