Detachable positioning tool suitable for fabricated building embedded part

A technology for positioning tooling and embedded parts, applied in the processing of building materials, construction, building structure, etc., can solve problems such as the difficulty of ensuring verticality, height, separation distance, horizontal deflection, and large area of anchor bolts , to achieve the effect of stable and reliable overall structure, improved precision assembly and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

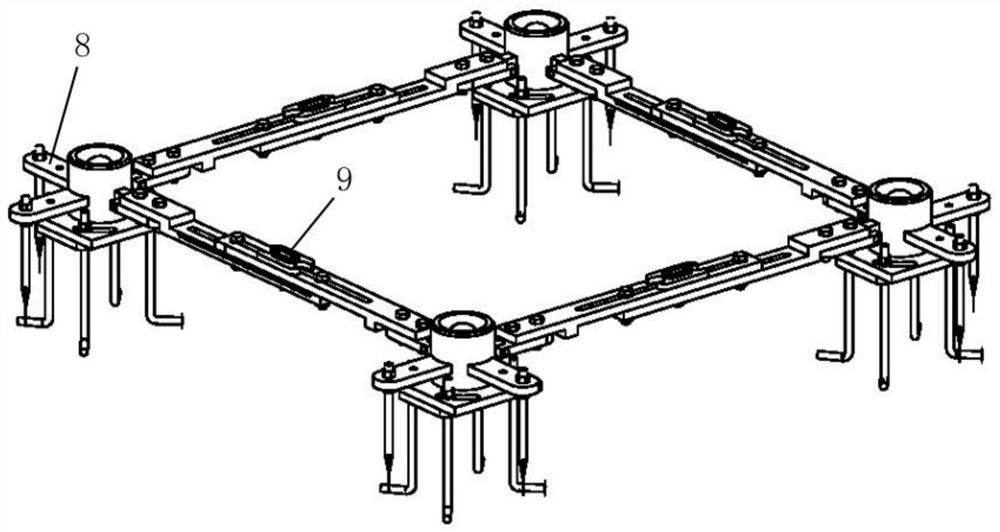

[0033] image 3 and Figure 4 It shows the second embodiment of the detachable positioning tooling suitable for the prefabricated building embedded parts of the present invention, the positioning tooling is basically the same as the first embodiment, the only difference is: in this embodiment, the positioning sleeve 4 is provided with There is a height adjustment mechanism 8. The height adjustment mechanism 8 can adjust the height of the positioning sleeve 4 at each node position, and the positioning sleeve 4 drives the guide plug-in column 1 to realize the height adjustment of the embedded parts at each node position, thereby ensuring the consistency of the height of all embedded parts.

[0034] In this embodiment, the height adjustment mechanism 8 includes a ground screw 81, an adjustment nut 82, and an adjustment ear 83 fixed on the positioning sleeve 4. The ground screw 81 is threaded on the adjustment ear 83 and inserted vertically in the pre-embedded area. On the other...

Embodiment 3

[0040] Figure 5 and Figure 6 It shows the third embodiment of the detachable positioning tooling suitable for the prefabricated building embedded parts of the present invention, the positioning tooling is basically the same as the embodiment 2, the only difference is: in this embodiment, the top of each positioning sleeve 4 All are provided with the air bubble instrument 7 that is used for detecting its perpendicularity. The positioning sleeve 4 at each node position is adjusted by using the air bubble meter 7 on the top of the positioning sleeve 4, and the positioning sleeve 4 is used to drive each guide plug-in column 1 to be adjusted to be vertical, thereby improving the adjustment accuracy of verticality.

Embodiment 4

[0042] Figure 7 and Figure 8 It shows the fourth embodiment of the detachable positioning tooling suitable for the prefabricated building embedded parts of the present invention. There are a plurality of positioning holes 51, and the pre-embedded screw rod 3 is penetrated in the positioning holes 51 and locked by the positioning nut 52. The top of each positioning sleeve 4 is provided with a bubble meter 7 for detecting its verticality. Through the mutual cooperation of the embedded screw 3, the positioning hole 51 and the positioning nut 52, the horizontal deflection of the embedded part can be prevented to ensure the precise assembly with the superstructure; The positioning sleeve 4 is used to drive each guide plug-in column 1 to be adjusted to be vertical by using the positioning sleeve 4, which improves the adjustment accuracy of the verticality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com